Seed bud recognition sensor of sugarcane cutting machine

A sensor and sugarcane technology, applied in instruments, measuring devices, metal processing, etc., can solve the problems of lack of intelligent identification of sugarcane seed buds, lack of automatic mechanical cutting equipment, etc., to achieve standardized production, improve cutting efficiency, and diameter change gentle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

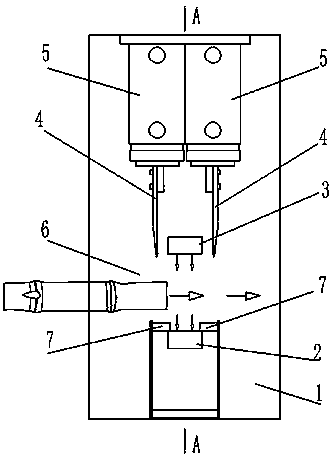

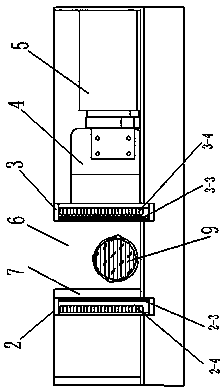

[0025] The seed bud recognition sensor of the sugarcane cutting machine includes a transmitting mechanism 3 and a receiving mechanism 2, which are respectively installed on both sides of the sugarcane cutting channel 6, and the transmitting mechanism 3 is provided with a light source transmitting unit A3- 1 and the light source transmitting unit B3-2, the receiving mechanism 2 is provided with a signal receiving unit A2-1 and a signal receiving unit B2-2 installed in parallel.

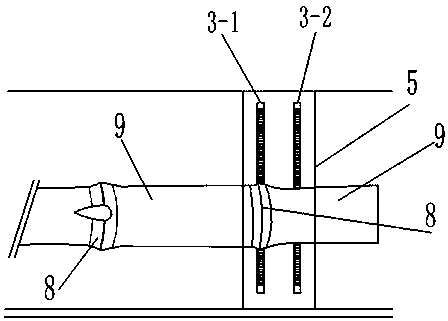

[0026] The parallel installation distance between the light source emitting unit A3-1 and the light source emitting unit B3-2 is 5mm to 10mm, and the two light source emitting units are equipped with a fixed grating 3-3 and a light source 3-4, and the fixed grating of the light source emitting unit A3-1 It is misaligned with the fixed grating of the light source emitting unit B3-2 by half a grid gap.

[0027] The parallel installation distance between the signal receiving unit A2-1 and the signal recei...

Embodiment 2

[0033] Both sides of the sugarcane cutting passage 6 are respectively provided with cutting knives 4 and chopping boards 7, and the launch mechanism 3 is installed on the center of the two cutting knives 4 or on the left of the center, and the direction of the light source rays is the same as the cutting direction of the cutting knives 4. At an angle of 90 degrees or close to 90 degrees with the sugarcane moving direction, the receiving mechanism 2 is installed in the middle of the two chopping boards 7, and the transmitting mechanism 3 and the receiving mechanism 2 can also be installed at the sugarcane entrance outside the double cutter, or at the same time in the above positions A plurality of launching mechanisms 3 and receiving mechanisms 2 are installed.

Embodiment 3

[0035] The light source of the transmitting mechanism 3 is an LED, and the detection element of the receiving mechanism 2 is a photodiode, which may also be a through-beam laser sensor or a diffuse reflection laser sensor.

[0036] When the present invention works, the seed bud identification sensor automatically recognizes the position of the sugarcane node containing the sugarcane seed bud. When the sugarcane node is at the center of the double cutting knives, the cylinder pushes the cutting knife to cut the sugarcane into sections, and then proceeds to the next sugarcane node. Identify and cut segments, and cycle in turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com