Design method of micro texture having flat wall surface drag reduction function

A design method and microtexture technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the problems of large amount of simulation, high cost, and no theoretical basis for design parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

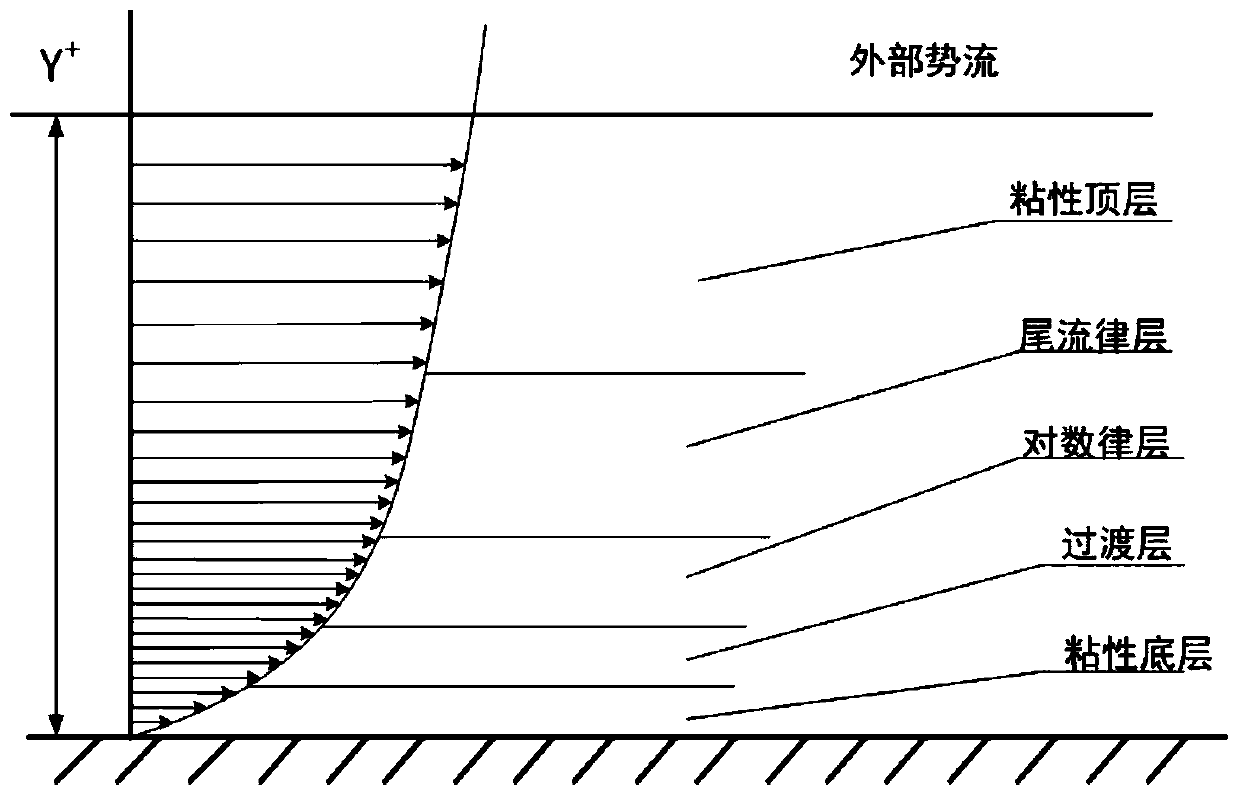

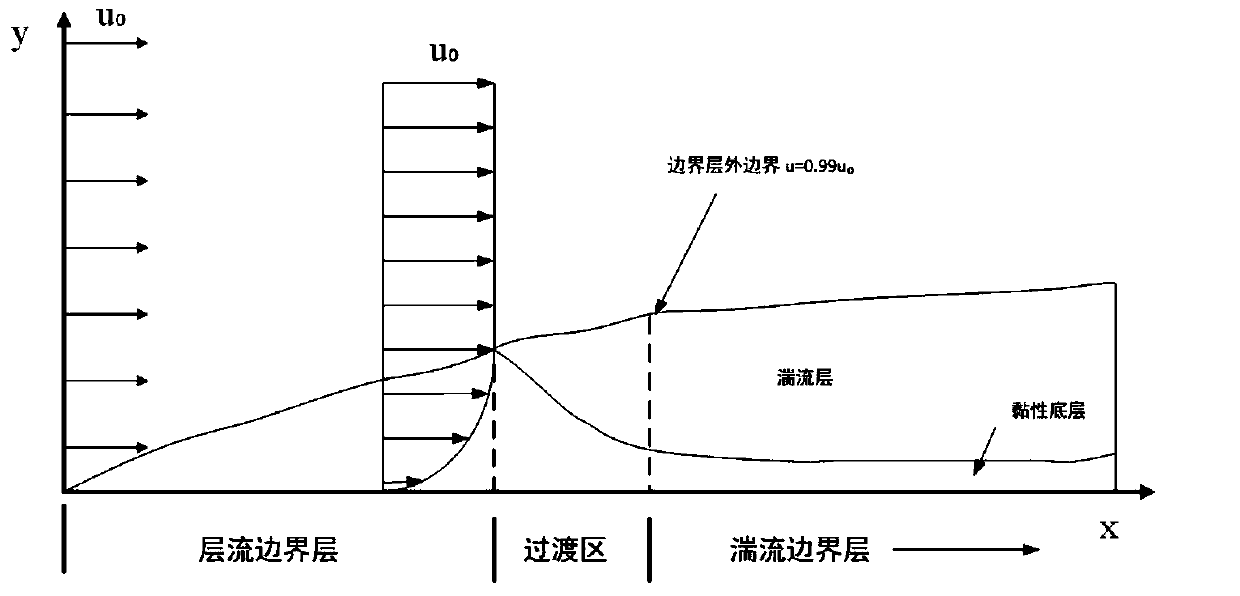

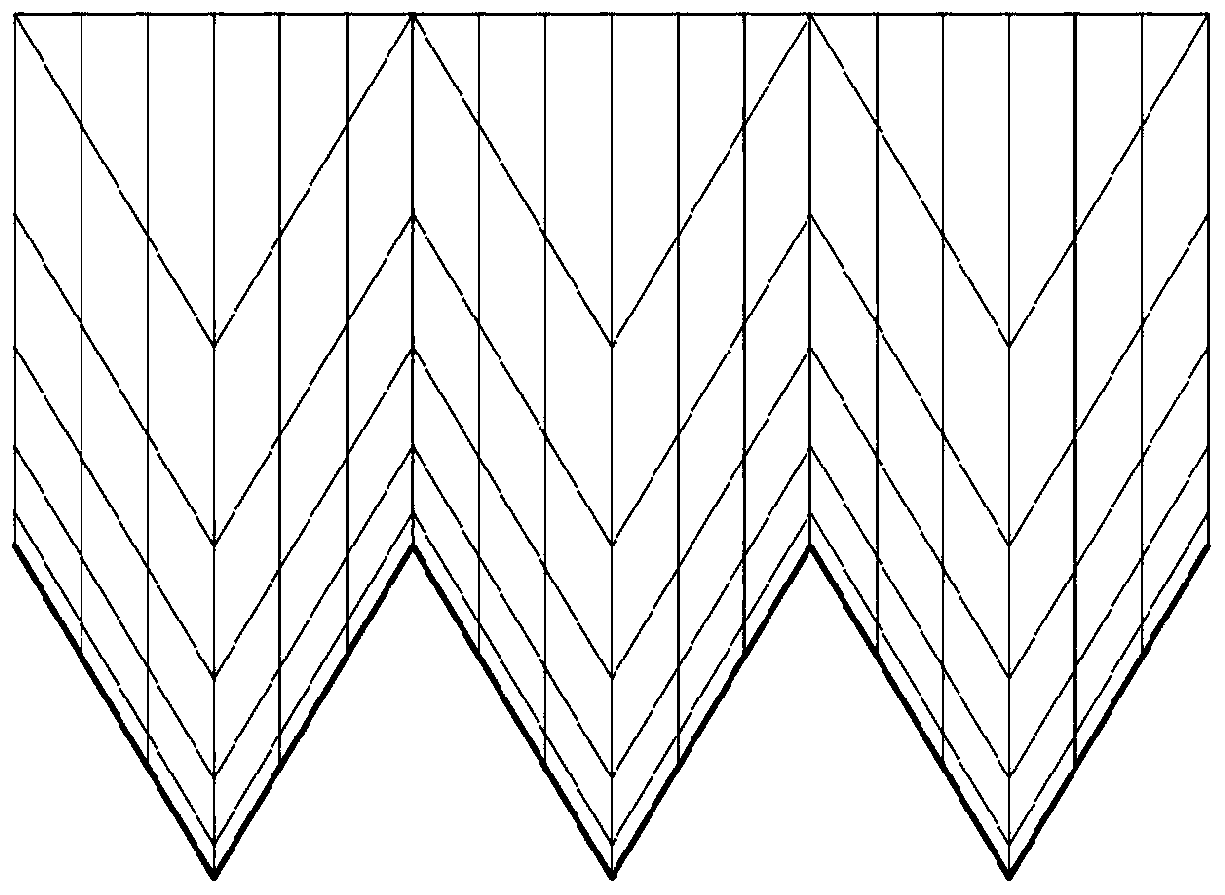

[0041] Designed for the drag-reducing micro-texture of the flat wall. First, the division of the boundary layer near the wall is analyzed to determine the action area of the microtexture and calculate the thickness of this area. Secondly, the design range of size parameters and position parameters of the drag-reducing micro-texture is determined according to the dimensionless equation. Finally, computational fluid dynamics calculations are realized through finite element simulation to verify and optimize microtexture parameters.

[0042] 1. Divide the boundary layer

[0043]According to Prandtl's boundary layer theory, in the flat wall turbulent flow, the boundary layer flow is laminar flow in front of the flat wall, and as the fluid continues to flow along the flat wall, the flow in the boundary layer transitions to turbulent flow . Divide the turbulent wall area into viscous bottom layer, buffer layer and logarithmic law layer, and make sure that the arrangement of tiny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com