Thermal shrinkage soldering tin ring

A solder ring and heat shrinkable technology, which is applied in the direction of welding/welding connection, electrical components, circuits, etc., can solve the problems of solder contact mixing, solder welding effect and hot melt adhesive effect, etc., to achieve simple and convenient processing and manufacturing, and improve Practicality, the effect of tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

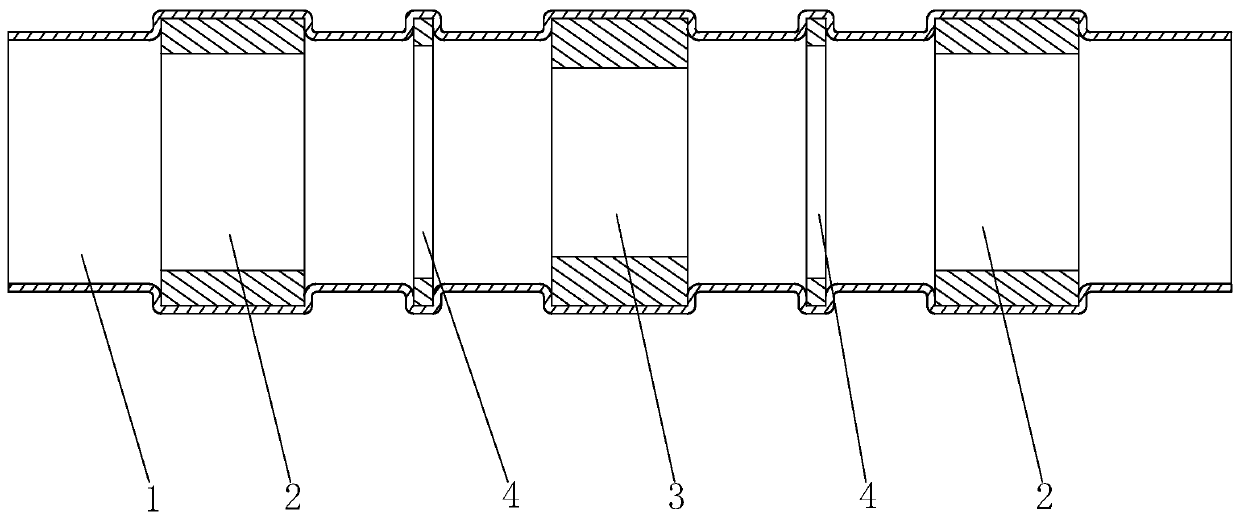

[0034] refer to figure 1 , is a heat-shrinkable solder ring disclosed in the present invention, including a heat-shrinkable tube 1, which is arranged as a sleeve with two ends open and a hollow inside. The heat-shrinkable tube 1 is provided with two rubber rings 2, the rubber rings 2 is tightened in the heat-shrinkable tube 1, and the rubber ring 2 is located on both sides of the heat-shrinkable tube 1 along its axial direction. The heat-shrinkable tube 1 is provided with a solder ring 3, and the solder ring 3 is stretched tightly in the heat-shrinkable tube 1, and the solder ring 3 is located in the middle of the heat-shrinkable tube 1 along its axial direction, that is, the solder ring 3 is located between the two plastic rings 2 between. A spacer 4 is provided between the solder ring 3 and the rubber ring 2, that is, there are two spacer rings 4, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com