Filter material and manufacturing method thereof

A filter material and production method technology, applied in the direction of filtration separation, membrane filter, separation method, etc., can solve the problems of high production cost and unsatisfactory filtration effect of air filter cloth, and achieve high adsorption, water absorption, and high water absorption Good performance and filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

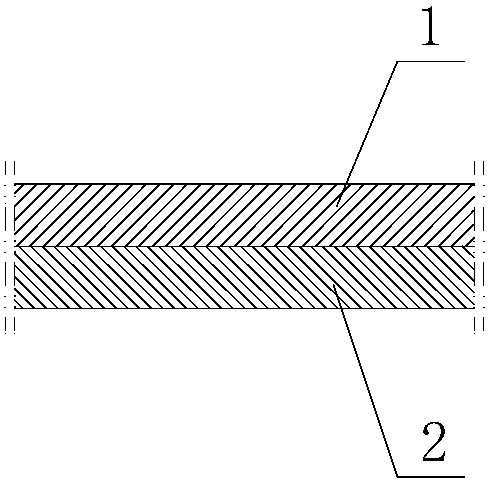

[0028] See figure 1 , The filter material includes the first mixed layer 1 obtained by mixing bamboo fiber with 4080 and hot pressing and forming, and also includes a polytetrafluoroethylene microporous film 2 attached to the first mixed layer 1 by hot pressing.

[0029] The thickness of the polytetrafluoroethylene microporous membrane 2 is less than or equal to 3 microns.

[0030] The thickness of the first mixed layer 1 is 0.35 cm to 0.52 cm.

[0031] A manufacturing method of filter material includes the following steps:

[0032] Step 1: Send one end of the rolled first mixed layer 1 between the upper roller and the lower roller of the hot press;

[0033] Step 2: Place one end of the rolled PTFE microporous membrane 2 on the surface of one end of the first mixed layer 1;

[0034] Step 3: Start the hot press, and with the rotation of the upper roller and the lower roller, the polytetrafluoroethylene microporous film 2 is closely attached to the surface of the first mixed layer 1.

[003...

no. 2 example

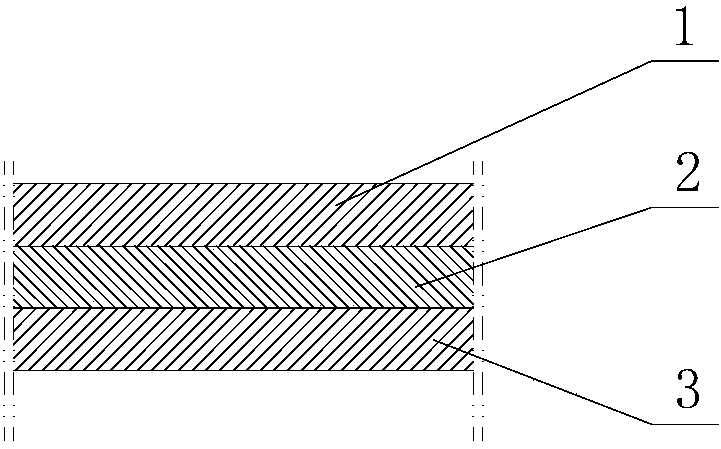

[0041] See figure 2 In this embodiment, the method for manufacturing the filter material further includes step four, sending one end of the first mixed layer 1 attached with the polytetrafluoroethylene microporous membrane 2 obtained in step three into the hot press Between the upper roller and the lower roller of the machine, one end of the second mixed layer 3 is sent between the upper roller and the lower roller of the hot press, and the PTFE microporous film 2 is located in the first mixed Between layer 1 and the second mixed layer 3; start the hot press, with the rotation of the upper and lower rollers, the PTFE microporous film 2 is closely attached to the surface of the first mixed layer 1 and the first Between the surfaces of the two mixed layers 3.

[0042] In this embodiment, a first mixed layer 1 and a second mixed layer 3 are respectively provided on both sides of the polytetrafluoroethylene microporous membrane 2. The first mixed layer 1 and the second mixed layer ...

no. 3 example

[0046] See figure 2 In this embodiment, the filter material also includes a second mixed layer 3 obtained by mixing bamboo raw fiber with 4080 and hot-press forming, and the polytetrafluoroethylene microporous membrane 2 is sandwiched between the first mixed layer 1 and the second mixed layer 3.

[0047] The thickness of the first mixed layer 1 and the thickness of the second mixed layer 3 are 0.35 cm to 0.52 cm, respectively.

[0048] A manufacturing method of filter material includes the following steps:

[0049] Step one, send one end of the first mixed layer 1 and one end of the second mixed layer 3 into the roll between the upper roller and the lower roller of the hot press; one end of the first mixed layer 1 and the second One end of the mixed layer 3 is crimped together;

[0050] Step 2: Insert one end of the rolled PTFE microporous membrane 2 between one end of the first mixed layer 1 and one end of the second mixed layer 3, and place one end of the PTFE microporous membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com