Composite waste gas purification mechanism based on spray absorption and photo-oxygen decomposition

A kind of exhaust gas purification and composite technology, which is applied in gas treatment, separation method, dispersed particle separation and other directions, can solve the problems of low exhaust gas purification efficiency, reduced exhaust gas purification effect, and increased labor input, etc., and achieves high treatment efficiency and exhaust gas treatment. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

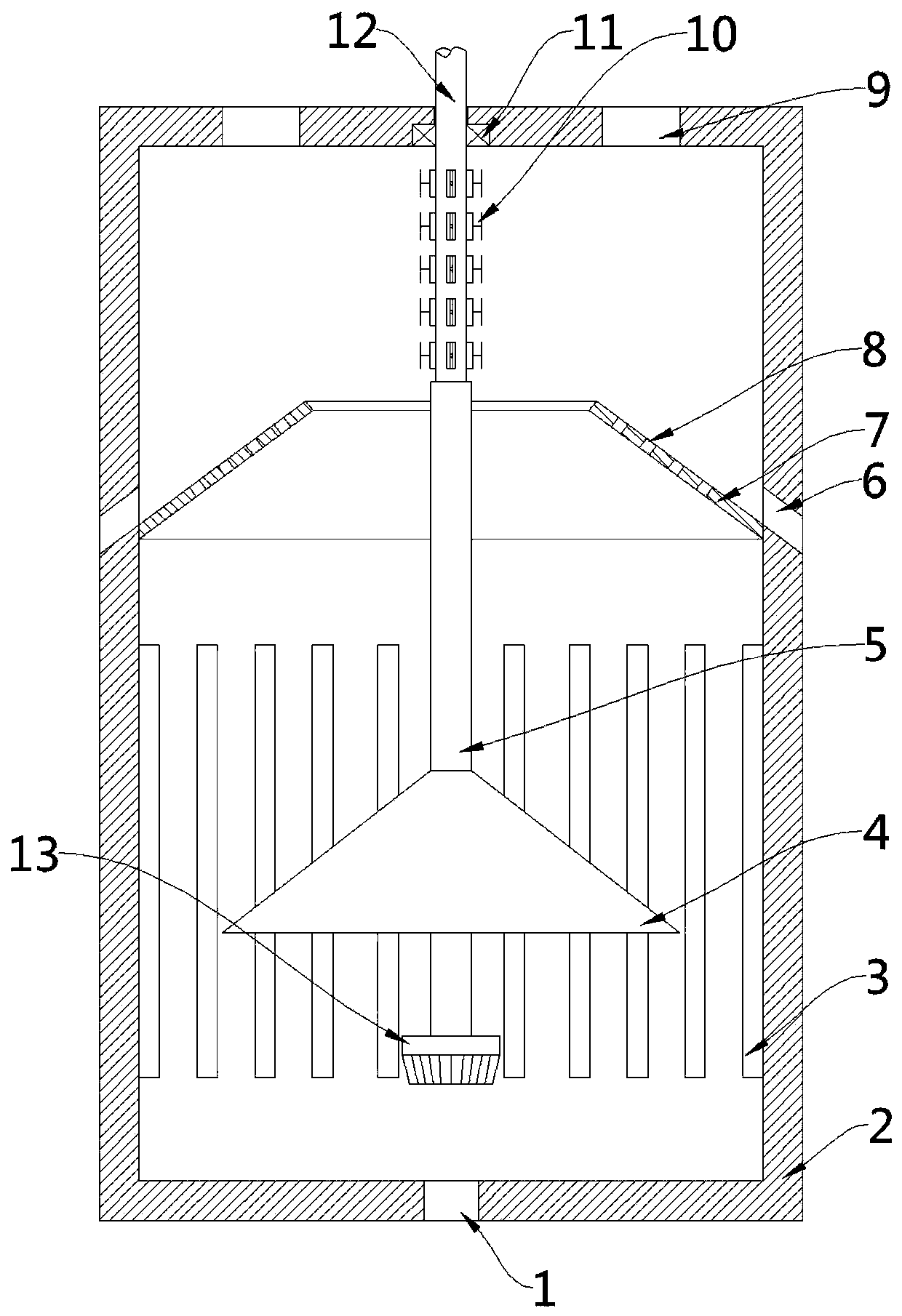

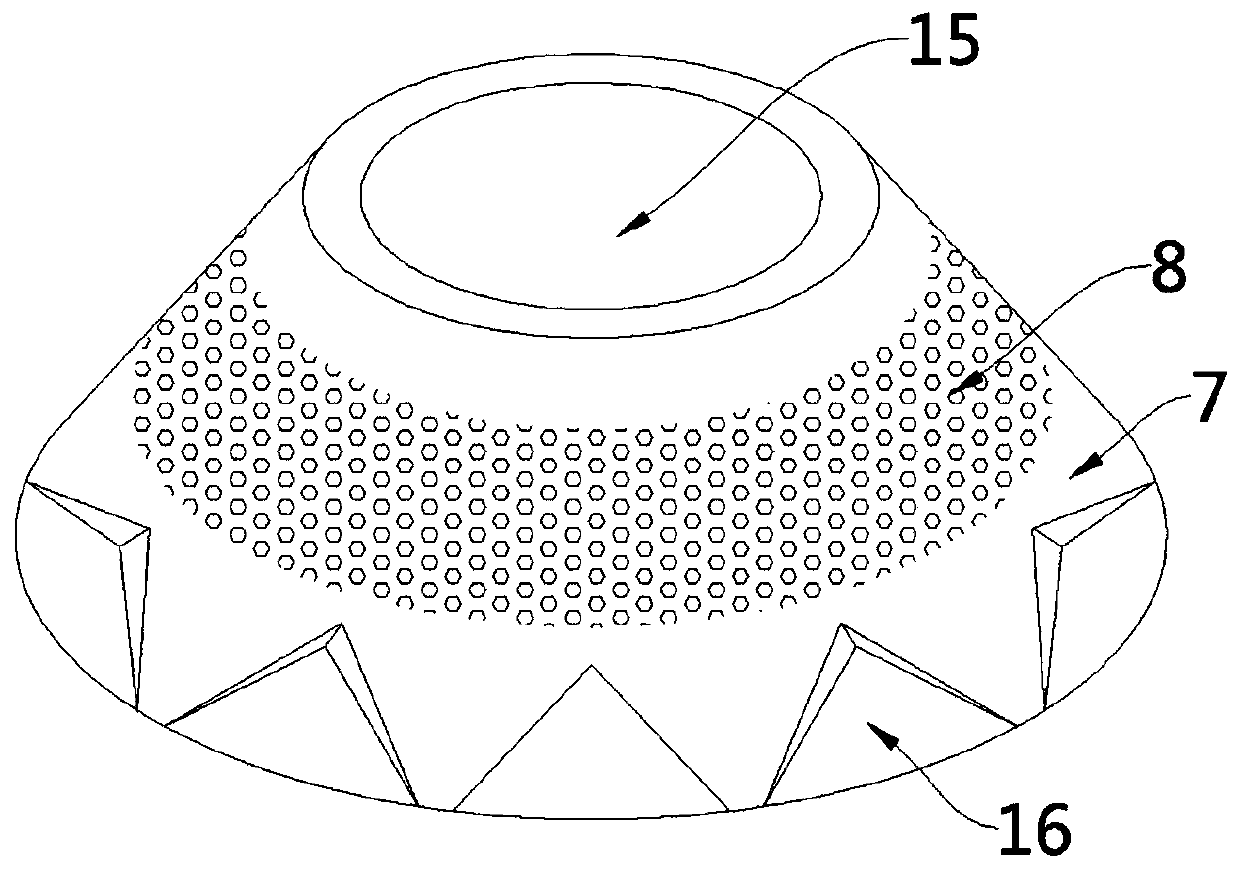

Embodiment 1

[0024] see Figure 1-2 , this embodiment provides a composite exhaust gas purification mechanism based on spray absorption and photo-oxygen decomposition, including a box body 2, an air inlet 1 is opened at the bottom of the box body 2, and an exhaust port is opened at the top of the box body 2 9. The inside of the box body 2 is provided with a photolysis component and a spray absorption component sequentially from bottom to top. Specifically, the photolysis component is a number of UV ultraviolet lamp tubes 3 evenly arranged along the inner wall of the box body 2. The spray absorption component The assembly includes a water pipe 12 extending from the top of the box body 2 to the inside of the box body 2 and several nozzles 10 arranged on the outer wall of the water pipe 12. The nozzles 10 are located inside the box body 2. A diversion cover 7 in a conical structure is provided, the diversion cover 7 is fixedly connected to the inner wall of the box body 2, the water pipe 12 i...

Embodiment 2

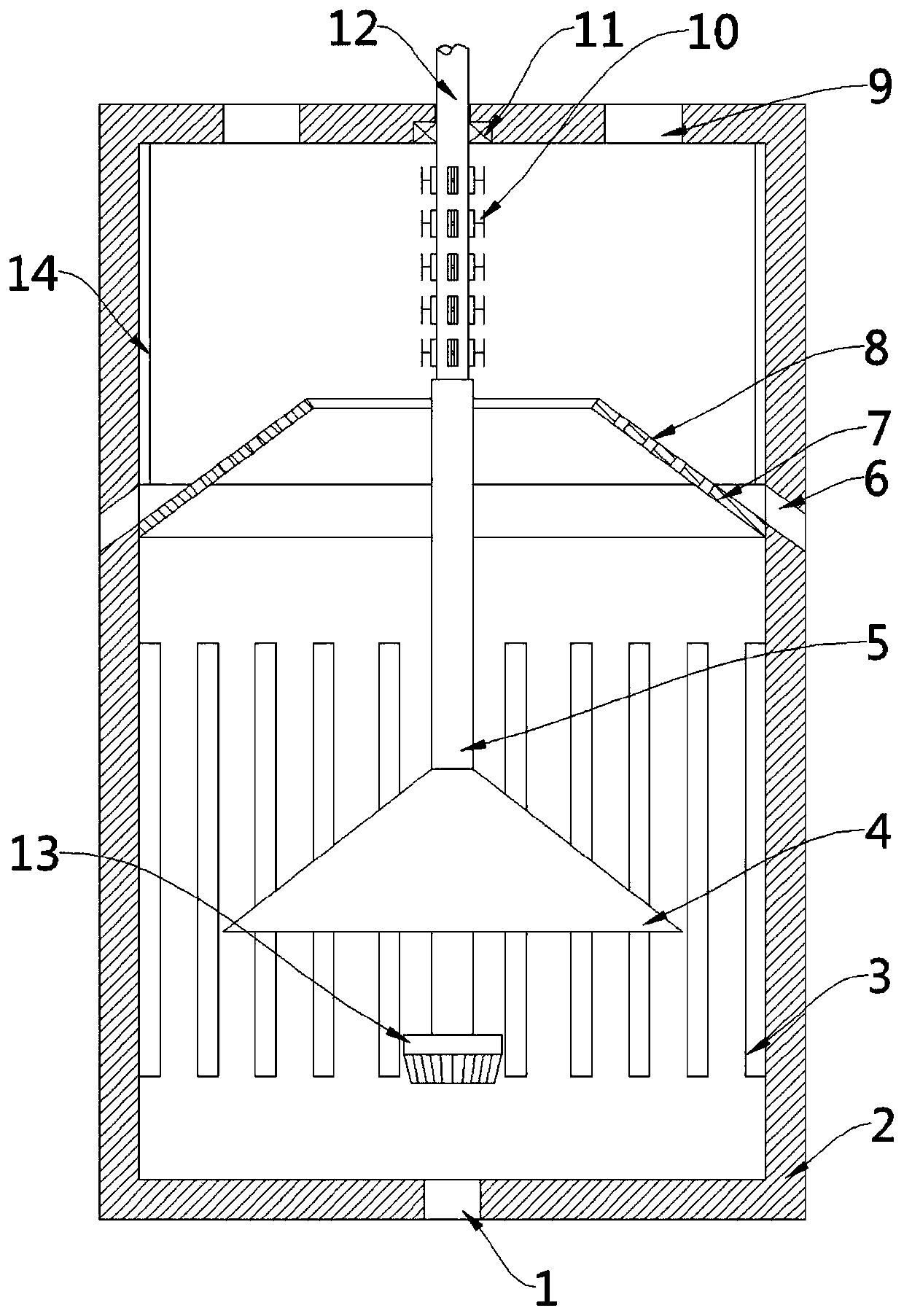

[0033] see image 3 , a composite exhaust gas purification mechanism based on spray absorption and photo-oxygen decomposition. Compared with Embodiment 1, this embodiment is provided with a water-retaining soft layer 14 attached to the inner wall of the box 2 above the inside of the box 2 , through the setting of the water-retaining soft layer 14, it can prevent the water ejected from the shower head 10 from directly hitting the inner wall of the casing 2, thereby causing a rebound phenomenon, so that the spray water carrying miscellaneous dust splashes everywhere.

[0034] Specifically, the water-blocking soft layer 14 is a sponge layer or a fleece layer.

[0035] In the embodiment of the present invention, through the combined application of the photolysis component and the spray absorption component, the waste gas generated in the rubber processing and drying production line can be effectively deodorized and dust-removed, which has the advantages of good waste gas treatment...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap