A rare gas adsorption and trapping device and its adsorption and trapping process and application

A rarefied gas and process technology, applied in measurement devices, separation methods, instruments, etc., can solve problems such as difficulty in analysis and detection, inability to use industrial production, etc., and achieve the effect of improving efficiency, increasing regeneration depth, and uniform gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

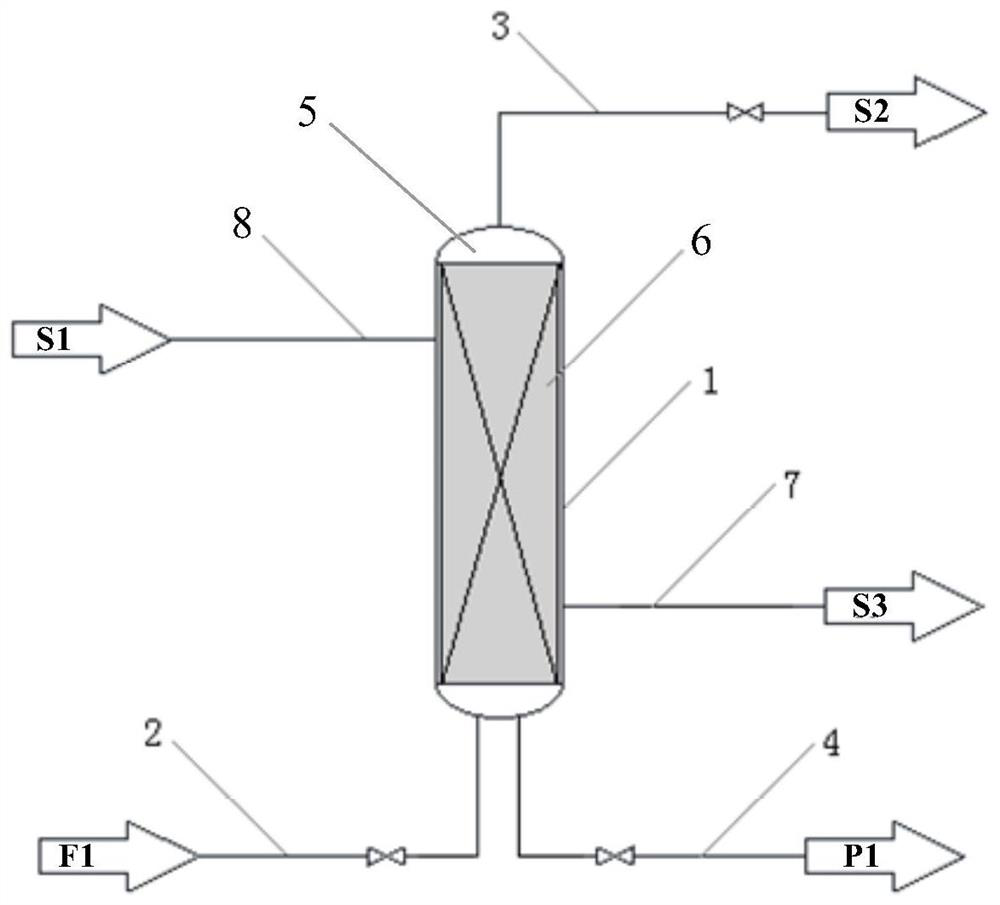

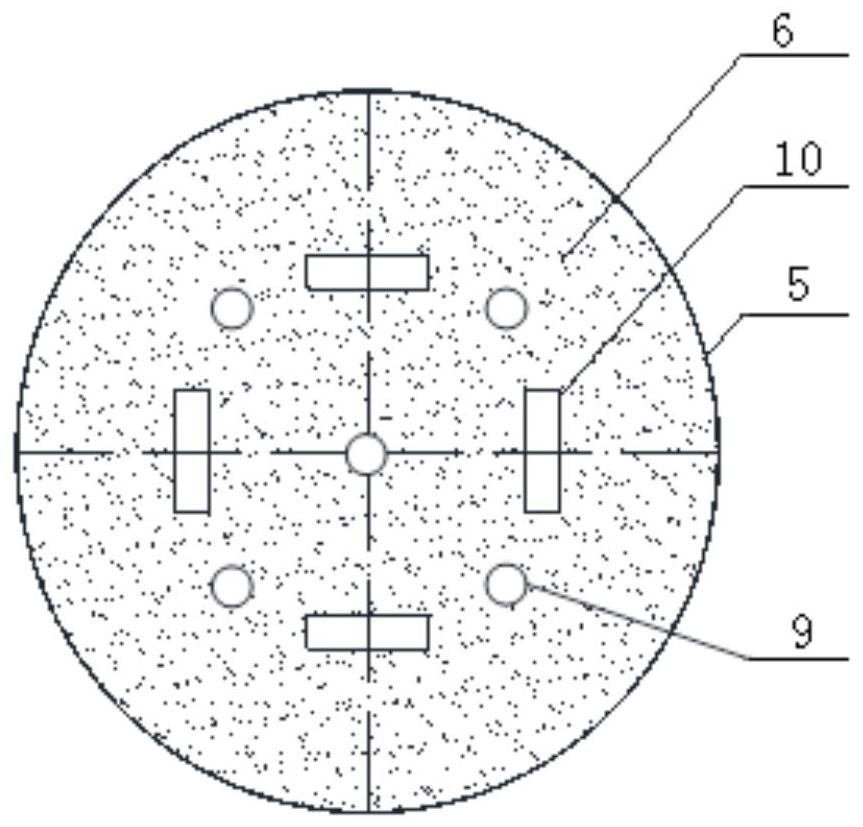

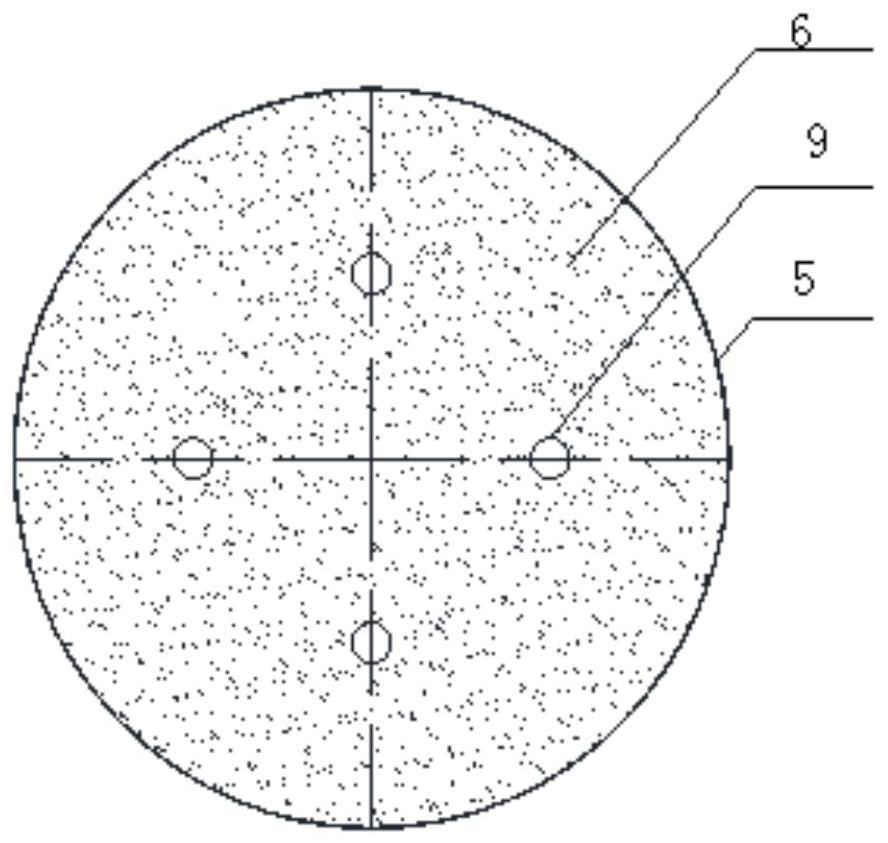

[0053] The volume of the adsorption bed is 5L, the loading of granular carbon molecular sieve is 2.5kg, the temperature of the feed gas (F1) is 25°C, the content of xenon is 0.001‰ (1ppm), the oxygen is 21%, the rest is nitrogen, and the adsorption space velocity is 0.1m / s. like figure 1 and figure 2 As shown, the adsorption cycle process is as follows: the raw gas (F1) enters the adsorber from the bottom, the unadsorbed gas (S2) flows out from the gas outlet at the top of the adsorber, and is adsorbed for 12 minutes at an adsorption temperature of 30 °C and an adsorption pressure of 0.3 Mpa, and then stops. Feed the raw material gas (F1); decompress in the forward direction for 30 seconds to -0.06Mpa, close the outlet of the unadsorbed gas (S2); then open the outlet of the product gas (P1), heat the adsorption bed by microwave to 50 ℃ and vacuumize in the reverse direction for 10 Minute to -0.08Mpa to collect the product gas (P1), then close the product gas (P1) outlet; ope...

Embodiment 2

[0055] The conditions of the adsorption bed and the feed gas are the same as those of Example 1. like figure 1 and figure 2 As shown, the adsorption cycle process is as follows: the feed gas (F1) enters the adsorber from the bottom, the unadsorbed gas (S2) flows out from the gas outlet at the top of the adsorber, and is adsorbed for 15 minutes under the conditions of adsorption temperature 30 °C and adsorption pressure 0.3 Mpa, and then stops. Feeding of raw material gas (F1); decompressing in the forward direction for 30 seconds to -0.06Mpa, closing the outlet of unadsorbed gas (S2) at the top of the adsorber; then opening the outlet of product gas (P1), heating the adsorption bed by microwave to 75°C and reversed Vacuum for 8 minutes to -0.08Mpa to collect the product gas (P1), then close the product gas (P1) outlet; open the feed gas (F1) inlet and the unadsorbed gas (S2) outlet; carry out the feed gas (F1) purge for 20 minutes Cool down to 30°C; then increase the pressu...

Embodiment 3

[0057] The conditions of the adsorption bed and the feed gas are the same as those of Example 1. like figure 1 and figure 2 As shown, the adsorption cycle process is as follows: the feed gas (F1) enters the adsorber from the bottom, the unadsorbed gas (S2) flows out from the gas outlet at the top of the adsorber, and is adsorbed for 15 minutes under the conditions of adsorption temperature 30 °C and adsorption pressure 0.3 Mpa, and then stops. Feed the raw material gas (F1); decompress in the forward direction to -0.06Mpa for 40 seconds, close the outlet of the unadsorbed gas (S2); then open the outlet of the product gas (P1), heat the adsorption bed by microwave to 90 ℃ and vacuumize in the reverse direction for 5 Minute to -0.08Mpa to collect the product gas (P1), then close the product gas (P1) outlet; open the feed gas (F1) inlet and the unadsorbed gas (S2) outlet; carry out the feed gas (F1) purge for 30 minutes and cool down to 30 ℃; then increase the pressure with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com