Method and apparatus for removing sulfur oxides and/or nitrogen oxides from catalytic cracking regeneration flue gas

A technology of sulfur oxides and nitrogen oxides, which is applied in the field of removing pollutants in industrial flue gas and removing sulfur oxides in industrial flue gas, and can solve the problem of the amount of sulfur transfer agent failure transfer aids, and the ineffective reduction reaction. Complete and other problems to achieve the effect of saving equipment investment, improving the utilization rate of heat energy and pressure, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0040] A method for removing sulfur oxides and / or nitrogen oxides in catalytic cracking regenerated flue gas provided by the present invention comprises:

[0041] (1) In the catalytic cracking regenerator, at a temperature of 650°C to 750°C, the desulfurization and denitrification additives and the catalytic cracking catalyst are in contact with the regenerated flue gas, and the sulfur oxides in it are adsorbed and removed, and the sulfur oxides in it are decomposed and removed. Nitrogen oxides, the desulfurization and denitrification additives are modified magnesium aluminum spinel and / or modified hydrotalcite;

[0042] (2) introducing the raw desulfurization and denitrification auxiliary agent and the regenerated catalytic cracking agent after the reaction in step (1) into the catalytic cracking reactor, contacting with catalytic cracking raw materials, and performing catalytic cracking reaction;

[0043] (3) Introduce the raw desulfurization and denitrification auxiliary ag...

Embodiment 1

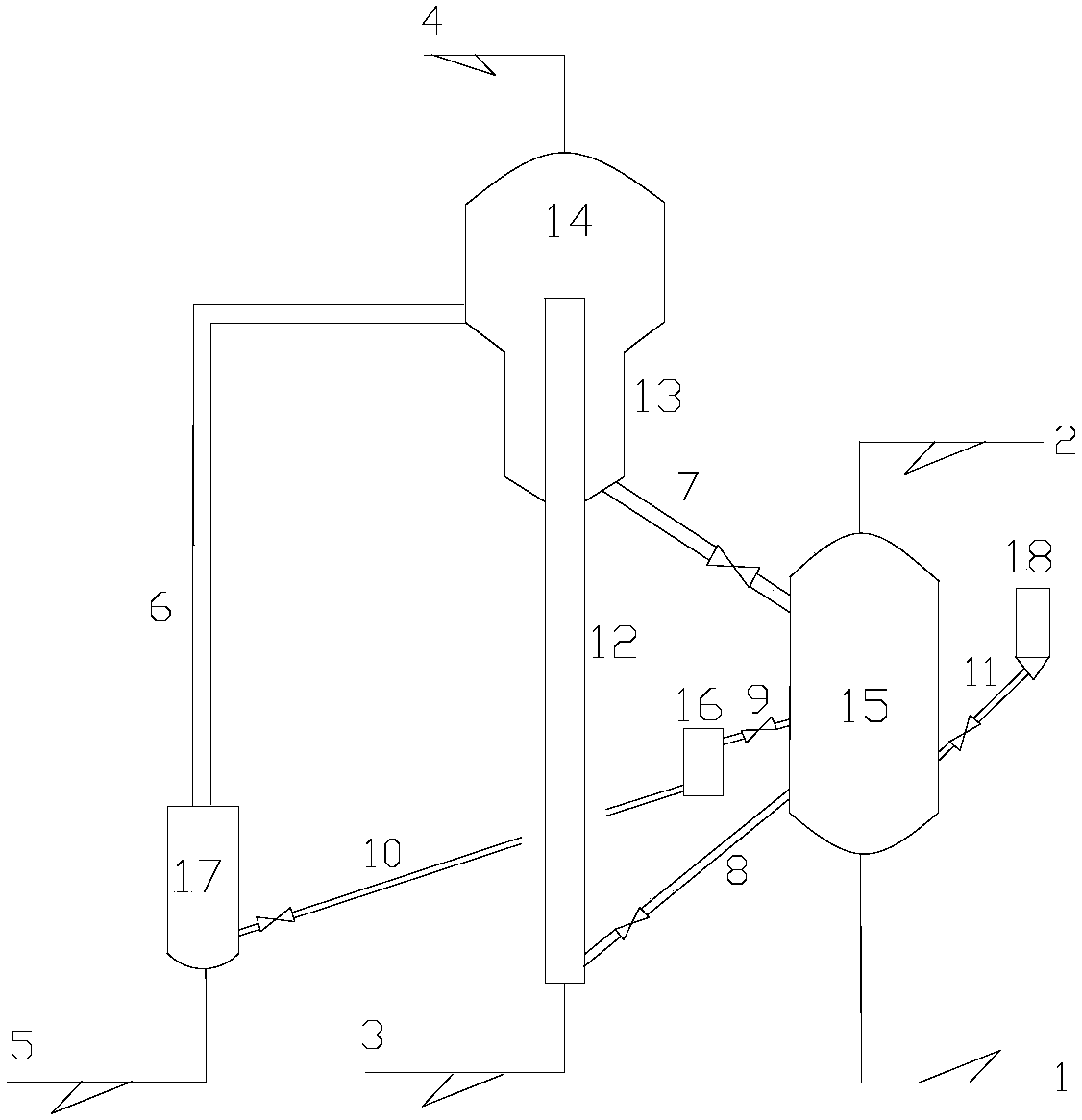

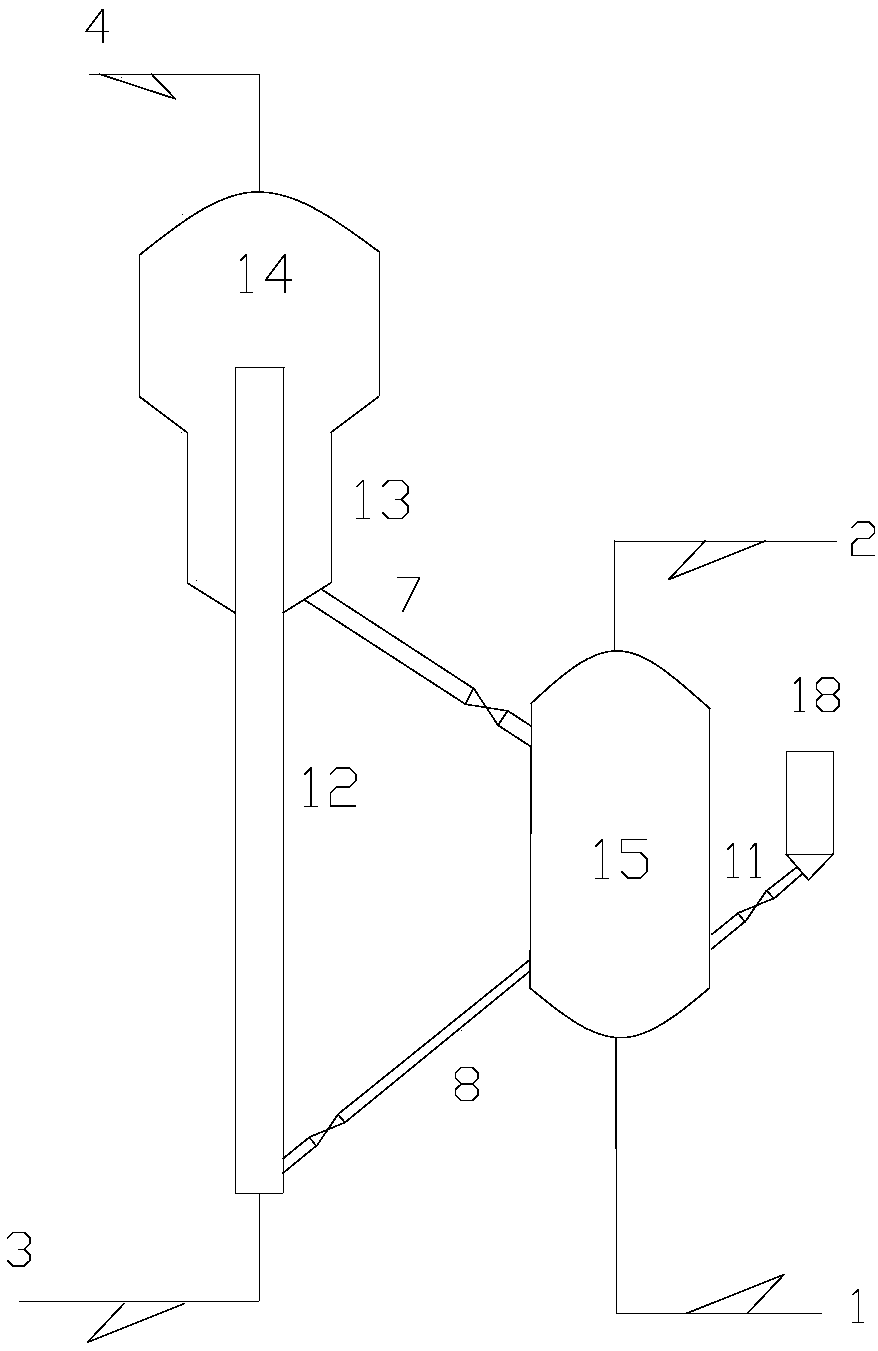

[0094] Adopt the catalytic cracking test device that the present invention provides with auxiliary agent regenerator, process flow chart is as attached figure 1 shown. The catalytic cracking reaction raw materials are the same as in Example 1, and the catalyst is an industrial balancer for catalytic cracking catalyst CGP-C.

[0095] In the catalytic cracking test device, the catalytic cracking reaction and regeneration conditions are the same as those of Comparative Example 1. The auxiliary agent regenerator adopts a riser reactor, and the packing density of the catalyst in the riser is 20kg / m 3 , the reaction time is 2.5s, the reaction temperature is 520°C, the reducing gas fed into the auxiliary agent regenerator is the dry gas from the catalytic cracking unit, and the regenerated catalytic cracking catalyst is directly returned to the stripping section of the catalytic cracking reaction part, The mass ratio of the catalyst entering the catalytic cracking reaction part to ...

Embodiment 2

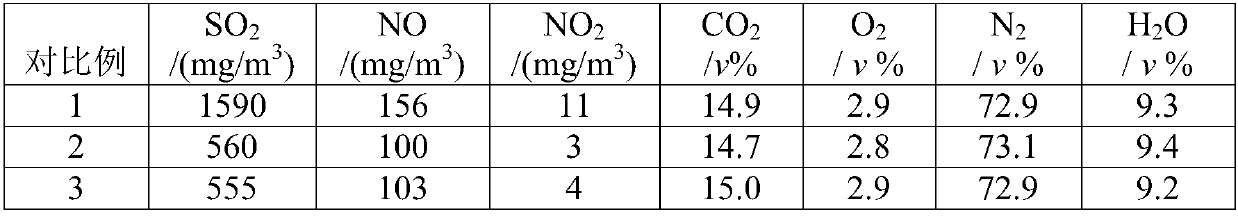

[0097] The catalytic cracking test device, catalytic cracking reaction raw material and method used are the same as in Example 1. The operating conditions of auxiliary agent regenerator and catalytic cracking reaction regeneration part are the same as embodiment 1.

[0098] The difference from Example 1 is that the catalyst is the industrial balancer of the catalytic cracking catalyst CGP-C and the desulfurization and denitrification auxiliary agent C-magnesium aluminum. The mass fraction of the desulfurization and denitrification auxiliary agent in the mixed catalyst is 3.0wt%, and the regeneration is measured after the operation is stable. The composition of the exhaust gas is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com