Low-temperature anti-degradation manufacturing method for small-particle-diameter suspending agent

A manufacturing method and suspending agent technology, which are applied in the fields of botanical equipment and methods, biocides, animal repellents, etc., can solve the problems of low production cost, reduce sanding time and times, reduce load, and reduce temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

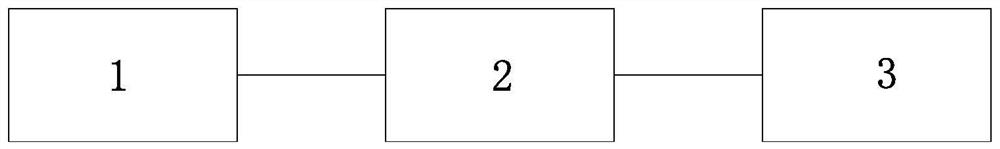

[0033] like figure 1 Shown, a kind of low-temperature anti-degradation manufacturing method of small particle size suspending agent comprises the following steps:

[0034] Step 1: adding the original drug to be ground into the jet mill 1, and after the grinding is completed, the original drug powder is obtained;

[0035] Step 2: Transfer the original drug powder obtained in step 1 to the pipeline crushing pump 2, and add auxiliary agents and water, wherein the auxiliary agents can be made of dispersants, wetting agents, thickeners, antifreeze agents, preservatives and One or more components in the defoamer, start the pipeline pulverizing pump 2 to pulverize, after the pulverization is completed, the original drug mixture is obtained, preferably, a screen is also provided between the pipeline pulverizing pump 2 and the sand mill 3 , the pore size of the sieve is less than or equal to 15 microns, that is, the raw drug mixture obtained by pulverization is filtered by a sieve wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com