Construction device and method for integrated construction of small-diameter pipeline maintenance

A construction device and small-diameter technology, which is applied in the field of construction devices for integrated construction of small-diameter pipeline maintenance, can solve the problems of unsuitable small-diameter pipelines, scattered construction procedures, and low construction efficiency, so as to improve construction accuracy and construction efficiency, The effect of reducing manual operation, taking into account structural stability and installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

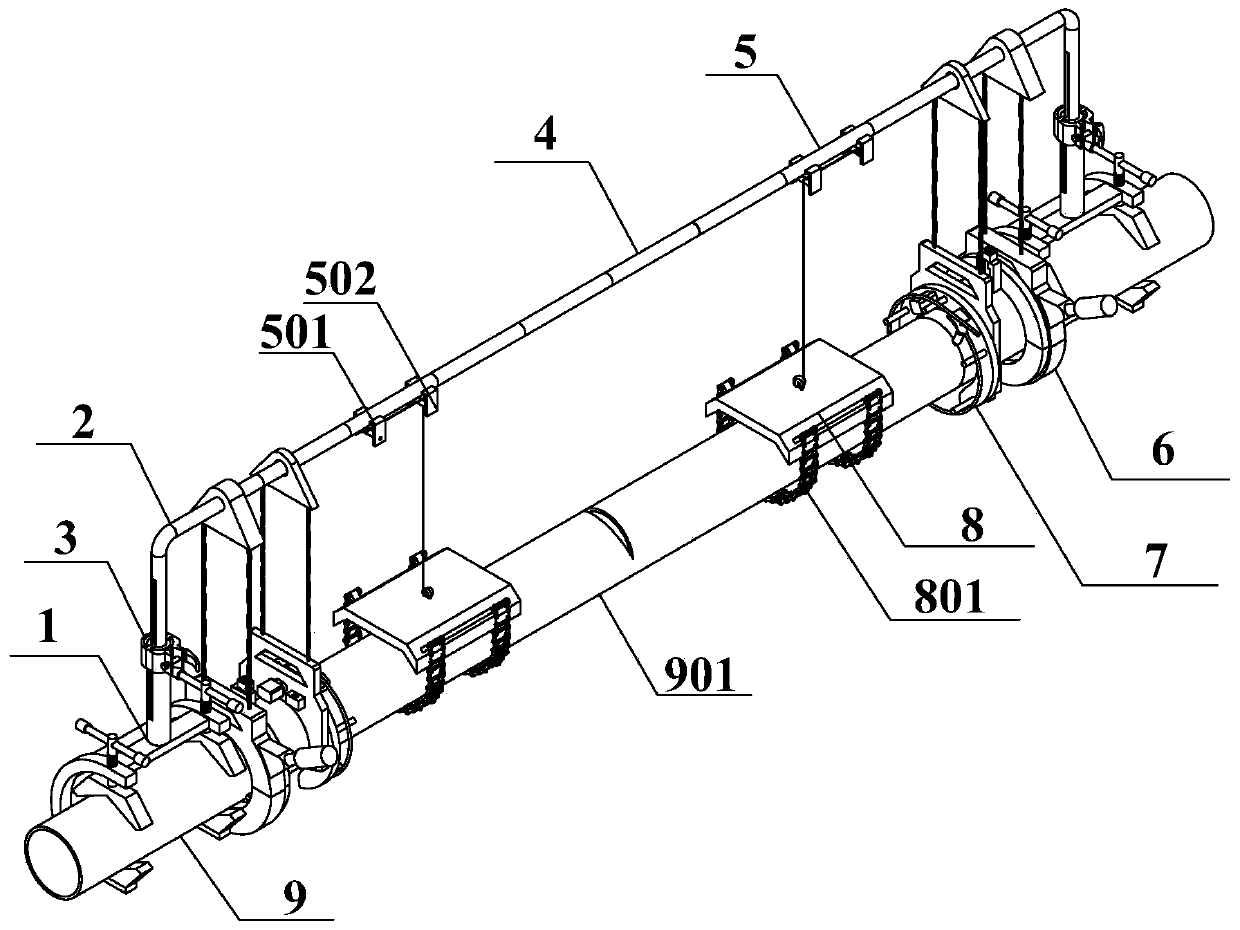

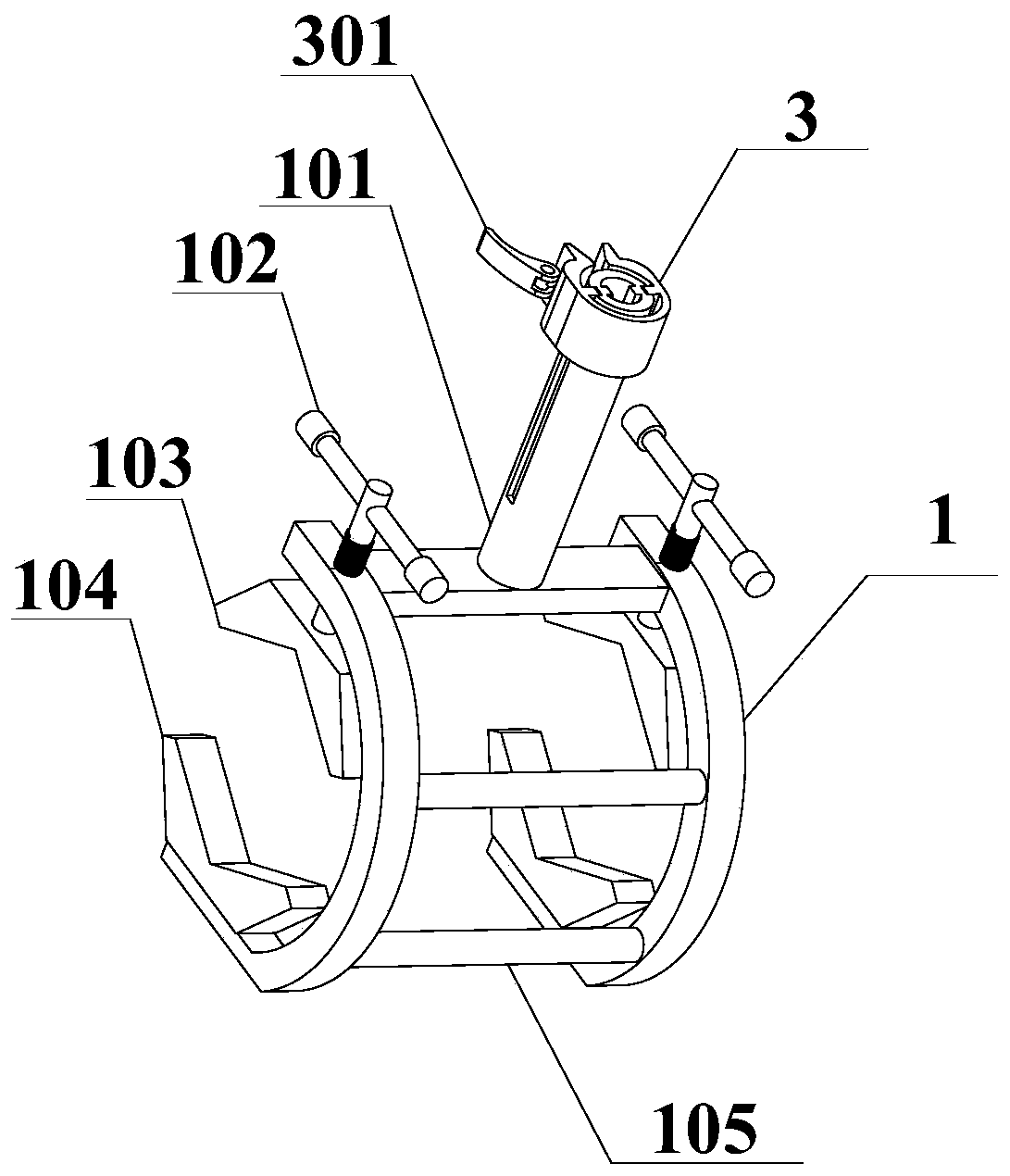

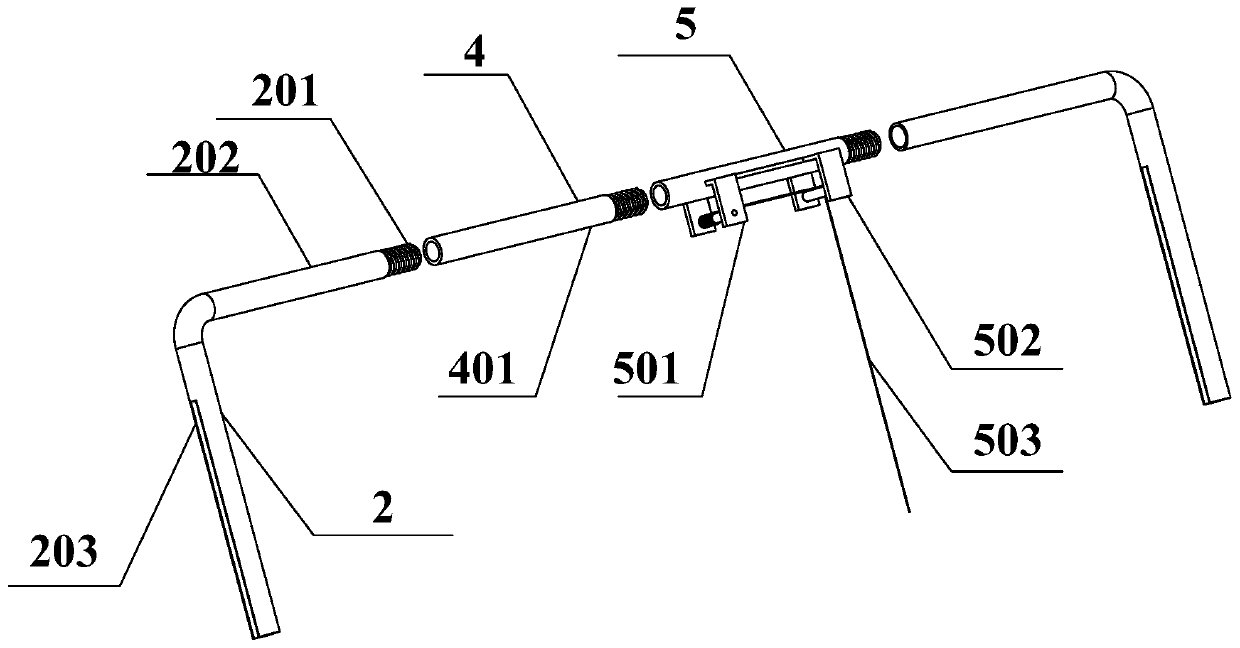

[0034] Figure 1 to Figure 6 As shown, a construction device for small-diameter pipeline maintenance integrated construction, including: a fixed frame 1, the main frame of the fixed frame 1 is roughly C-shaped, and there are a pair of V-shaped blocks on the left and right, and the V-shaped blocks are divided into V-shaped blocks. The upper block 103 of the shape block and the lower block 104 of the V-shaped block are screwed between the upper block 103 of the V-shaped block and the main body of the fixed frame 1, and the top of the upper block 103 of the V-shaped block is a rotary handle 102, which can be adjusted by turning the rotary handle 102. The vertical position of the upper block 103 is to clamp the pipeline; the lower block 104 of the V-shaped block is fixedly connected with the main body of the fixed frame 1; the left and right parts of the fixed frame 1 are connected by two cylindrical beams 105; the upper part of the fixed frame 1 It is a standpipe 101, the upper h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com