Brake separation type liquid metal grinding disc device

A liquid metal, braking device technology, applied in grinding devices, metal processing equipment, abrasives, etc., can solve the problems of waste materials, non-recyclable precision, complex processing technology, etc., achieve high flatness, ensure stability, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

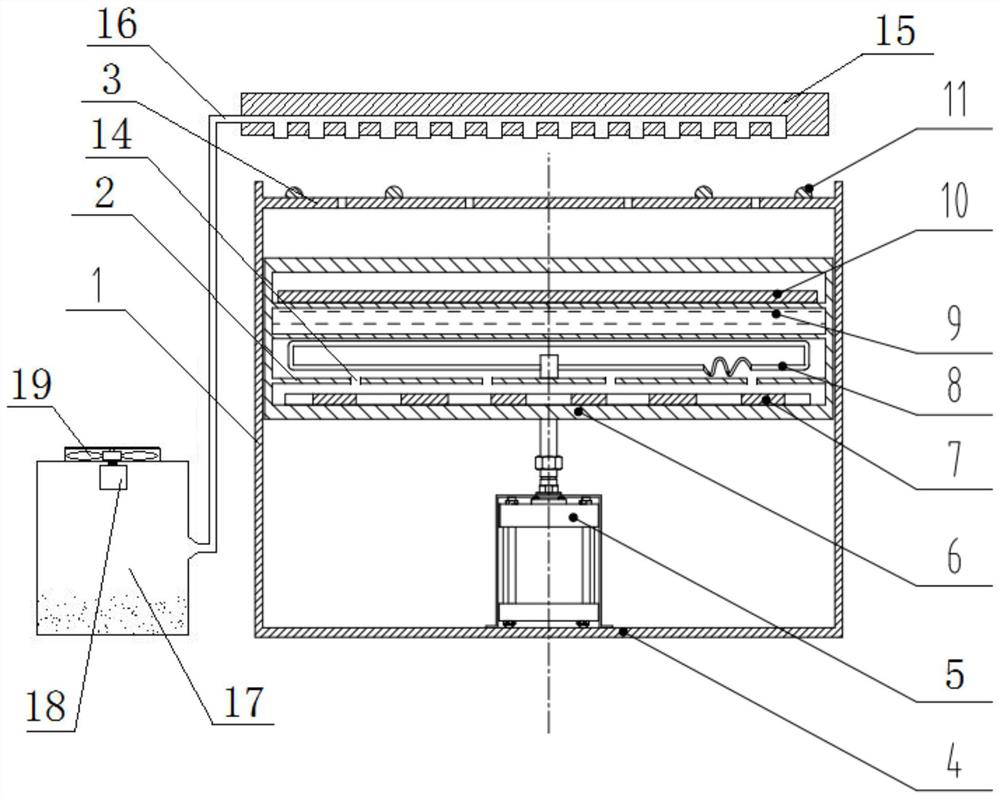

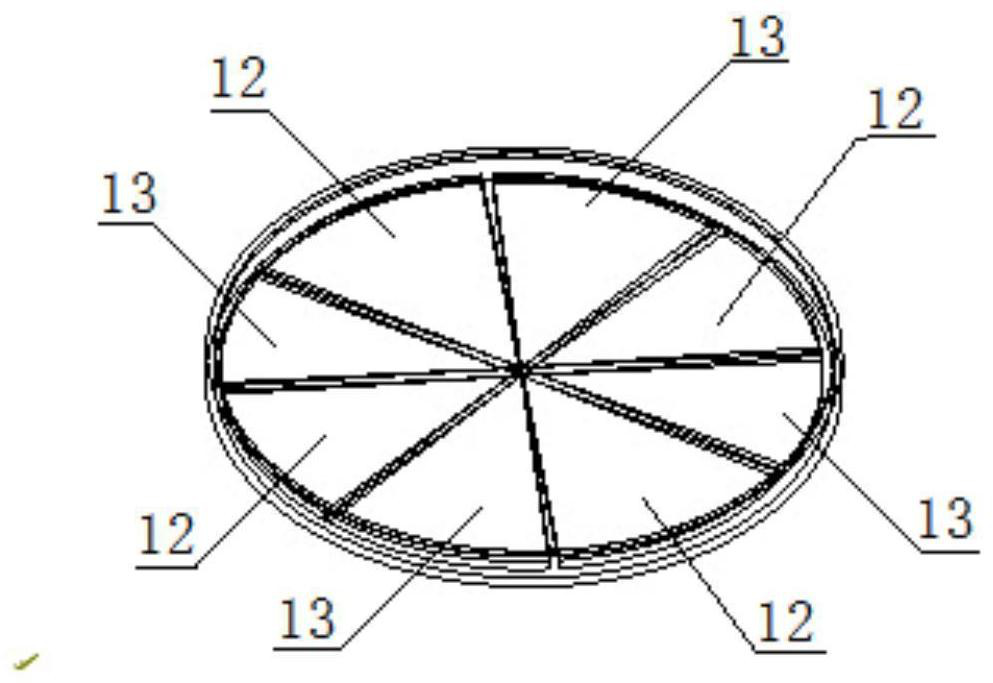

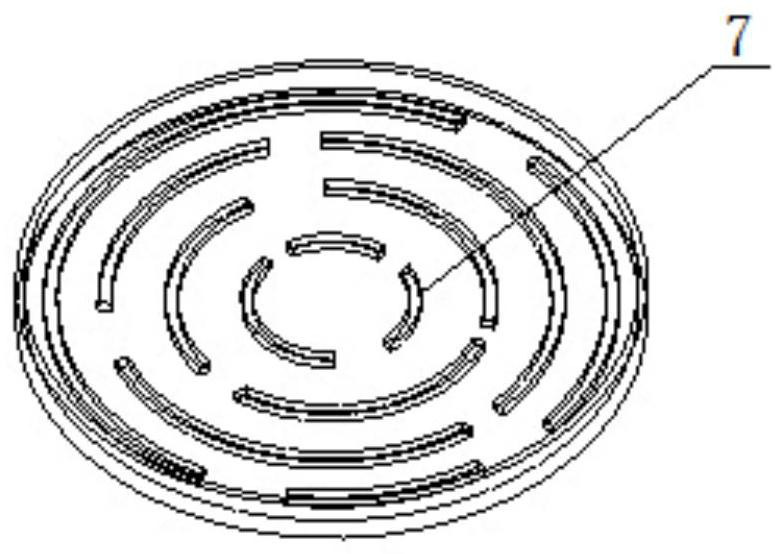

[0034] Such as Figure 1~3 As shown, a brake-separated liquid metal grinding disc device includes a cylinder barrel 1, a cylinder bottom plate 4, a cylinder top plate 3, a braking device and a driving cylinder 5, and the cylinder bottom plate 4 is fixed on a vertically arranged shaft. The bottom of the cylindrical cylinder 1, the braking device is in the shape of a cylindrical piston as a whole, the braking device is installed in the cylindrical cylinder 1, the driving cylinder 5 is vertically fixed on the cylinder bottom plate 4, and the movable end of the driving cylinder 5 is connected to The bottom of the brake device, when driving the cylinder 5 to move, pushes the brake device to move up and down along the inner wall of the cylinder barrel 1; the cylinder top plate 3 is installed on the cylinder barrel 1 inner wall near the upper end of the cylinder barrel 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com