A Surface Grinding Robot for Special Steel Bars Based on Parallel Drive Mechanism

A driving mechanism and robot technology, which is applied to the parts of grinding machine tools, manipulators, program-controlled manipulators, etc., can solve the problems of uncontrollable quality of grinding operations and large cumulative errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

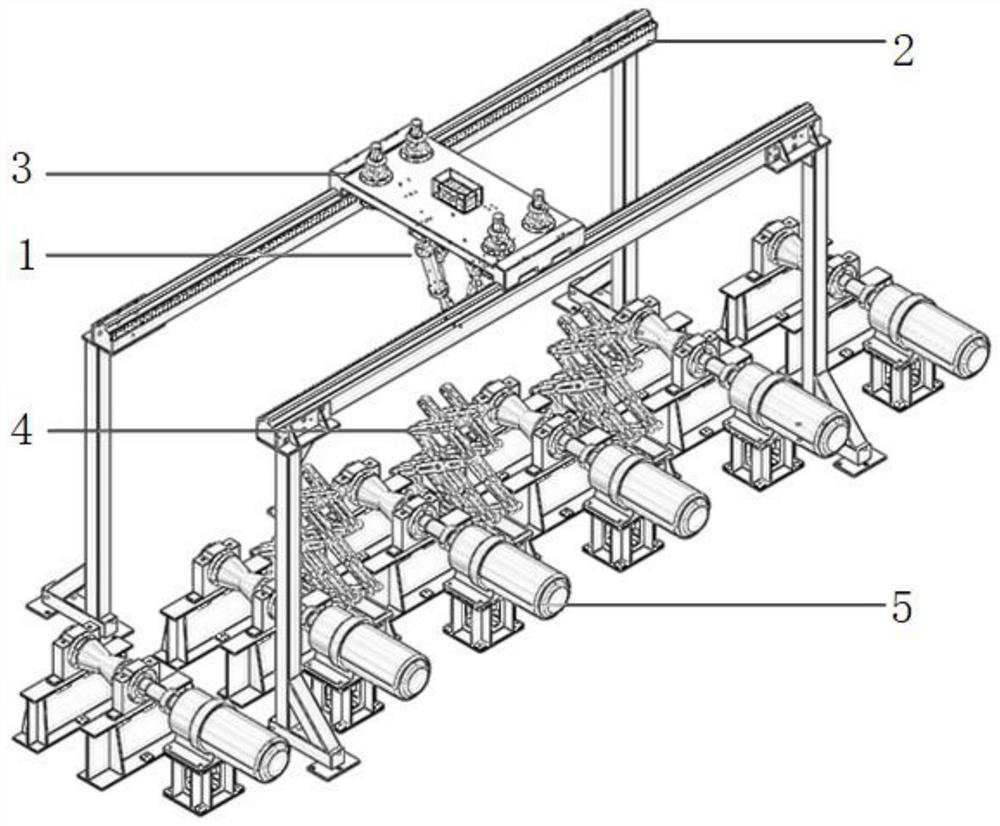

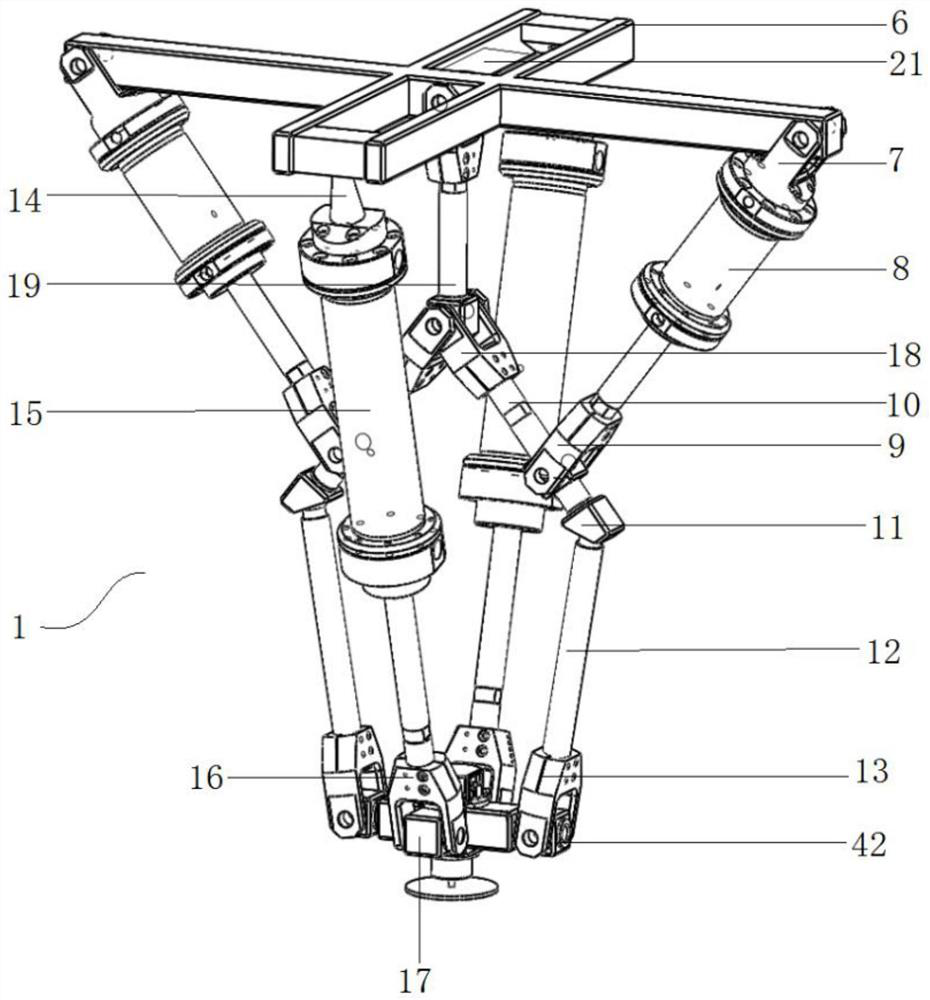

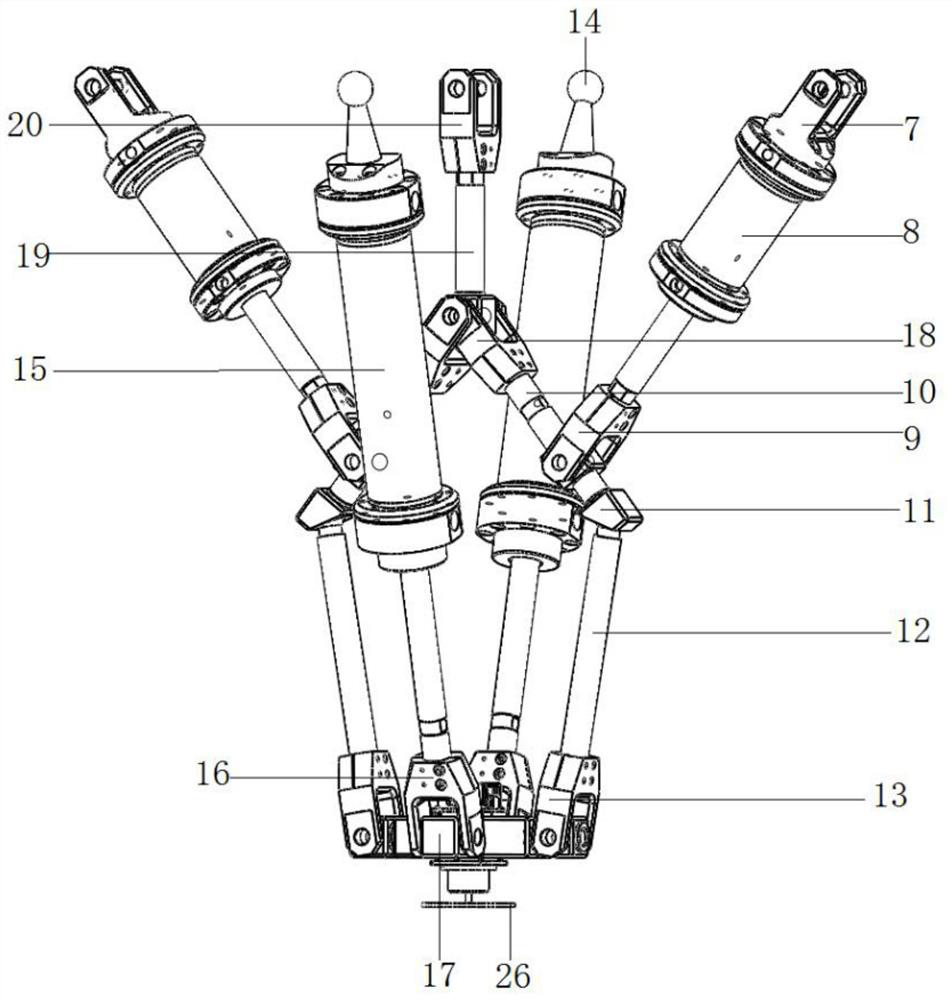

[0028] according to Figure 1-10 As shown, this embodiment provides a special steel bar surface grinding robot based on a parallel drive mechanism, including a five-degree-of-freedom grinding robot arm 1, a truss 2, a mobile platform and a controller 3, a bar lifting mechanism 4 and A roller table 5, a mobile platform and a controller 3 are movable on the truss 2, and a five-degree-of-freedom grinding mechanical arm 1 is installed below the mobile platform and the controller 3, and a bar is provided at the lower position of the truss 2 Lifting mechanism 4 and roller table 5, and there are multiple sets of bar lifting mechanism 4 and roller table 5;

[0029] The five-degree-of-freedo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com