Composite material front floor single bottom plate of passenger vehicle and preparation method

A composite material and front floor technology, which is applied to vehicle components, superstructure sub-assemblies, transportation and packaging, etc., can solve the problems of reduced product size accuracy, poor appearance integrity, and large number of inspection tools, so as to reduce assembly and manufacturing costs , low linear expansion rate, and the effect of reducing the weight of the bottom plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

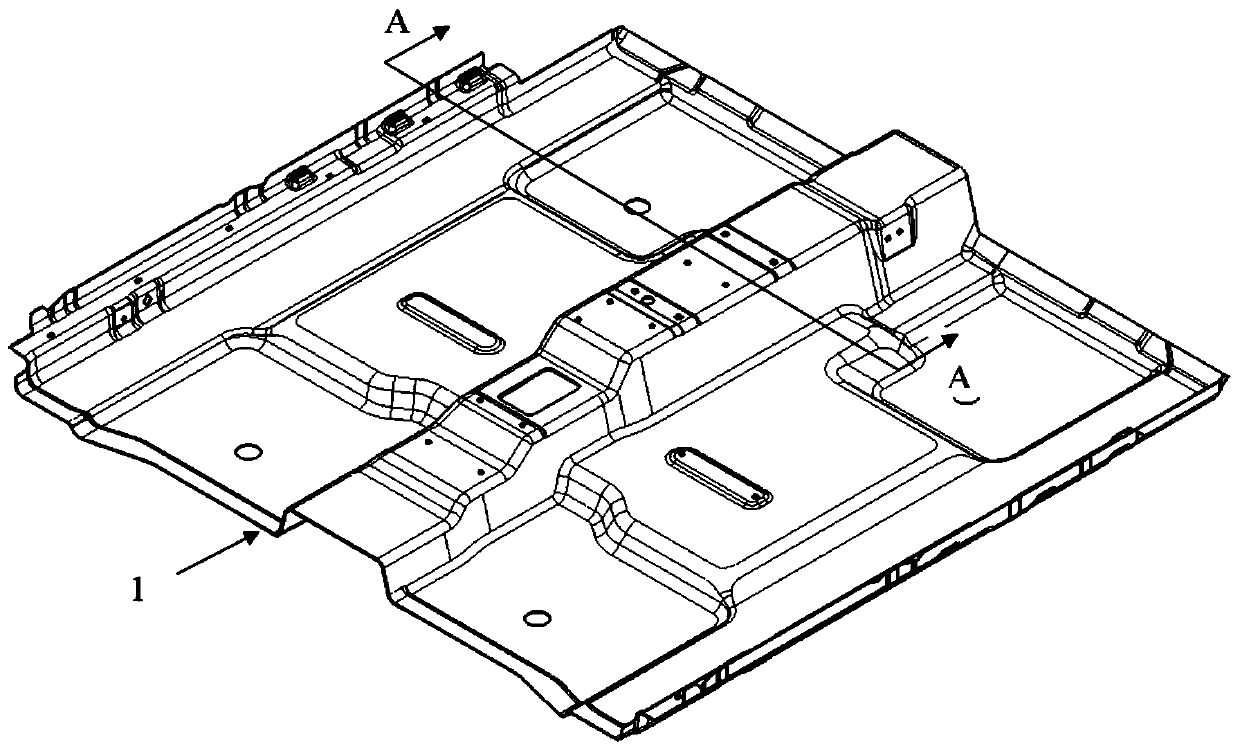

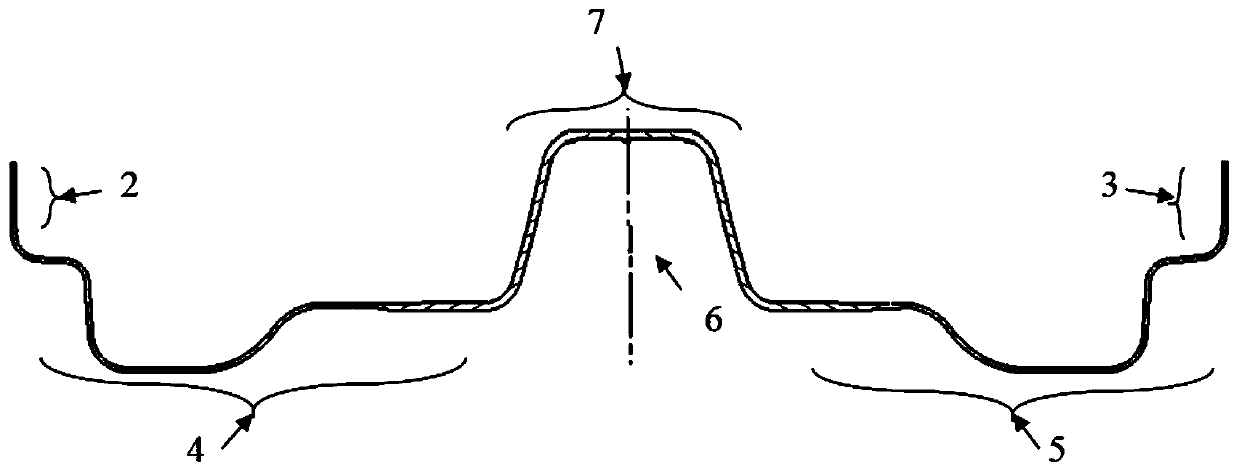

[0021] A passenger car composite material front floor single base plate, the single base plate 1 is a variable thickness base plate of composite material, wherein figure 1 is a schematic diagram of the overall structure of the single bottom plate 1, figure 2 It is a schematic diagram of the variable thickness structure of the single bottom plate 1 ( figure 1 Section A-A), the passenger car composite front floor is formed by a monolithic floor 1, which will be described in detail below.

[0022] The single bottom plate 1 integrates the left sill inner plate 2, the right sill inner plate 3, the left bottom plate 4, the right bottom plate 5, the central channel 6 and the central control box installation plate 7 into a single integral bottom plate, which improves the dimensional accuracy and Appearance integrity, reducing the number of molds, tooling and inspection tools, thereby reducing assembly and manufacturing costs.

[0023] In this embodiment, the left side sill inner pa...

Embodiment 2

[0025] This embodiment also provides a method for preparing a composite material front floor monolithic bottom plate of a passenger car, and the monolithic bottom plate 1 is manufactured by a composite material molding process.

[0026] In this embodiment, the composite material is a carbon fiber epoxy resin prepreg (ACTECH1201 / SYT45, manufactured by AVIC Composite Materials Co., Ltd.), and the carbon fiber epoxy resin prepreg has the advantages of easy integration, large-scale manufacturing, and low curing shrinkage. With the characteristics of low linear expansion rate, through the variable thickness structure design, it is solidified and formed on a single molding mold at one time, which saves the welding process, improves the manufacturing efficiency, and greatly reduces the weight of the bottom plate.

[0027] Among them, the carbon fiber epoxy resin prepreg is made by the following method: after adding 6% of the curing agent and 6% of the accelerator to the liquid epoxy r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com