A method for efficient hydrogen production based on biomineralization of chlorella cells

A cell biology, chlorella technology, applied in microorganism-based methods, biochemical equipment and methods, chemical instruments and methods, etc., can solve problems such as high cost, inability to achieve large-scale hydrogen production, cumbersome processes, etc., and achieve time The effect of short, high stability and high hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

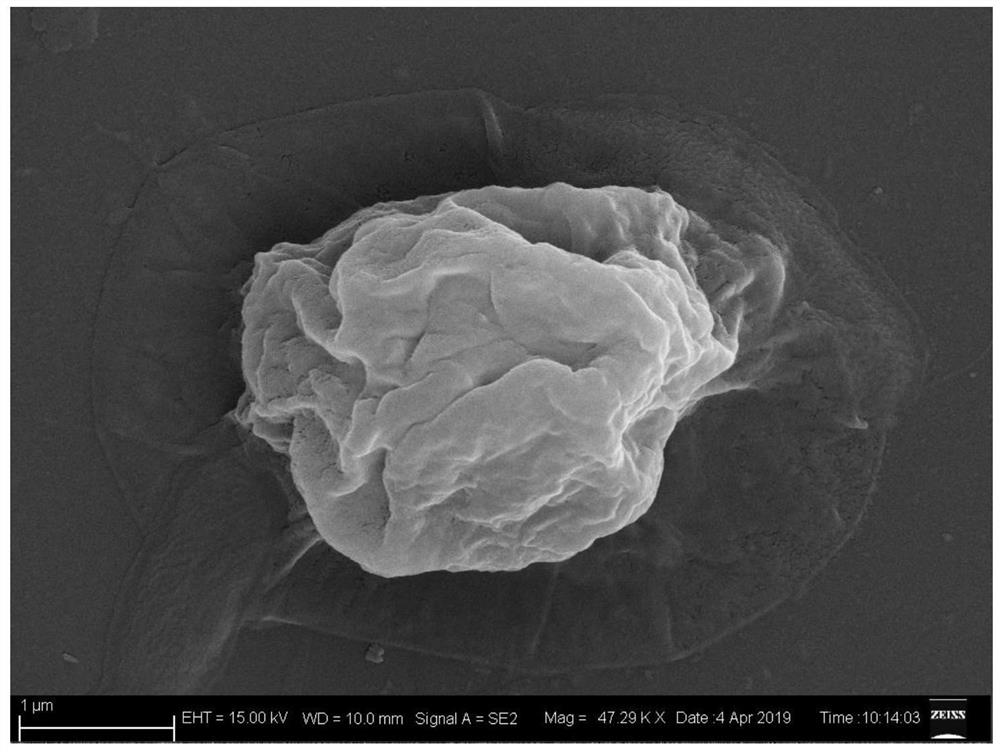

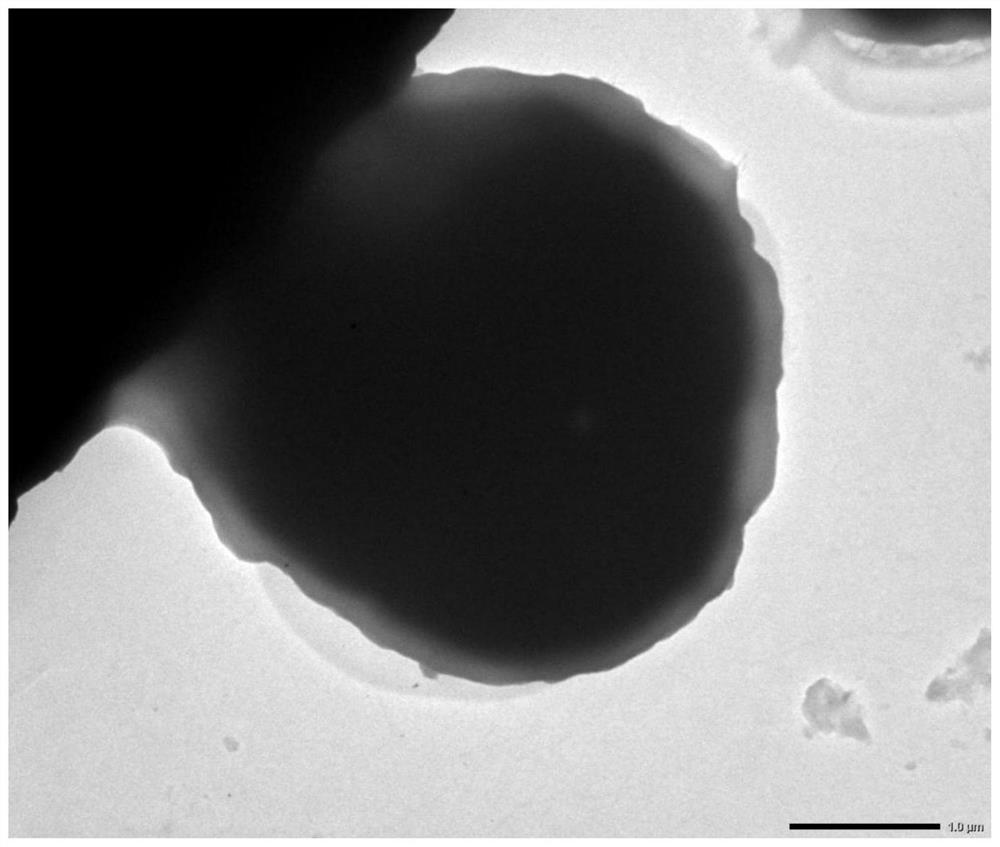

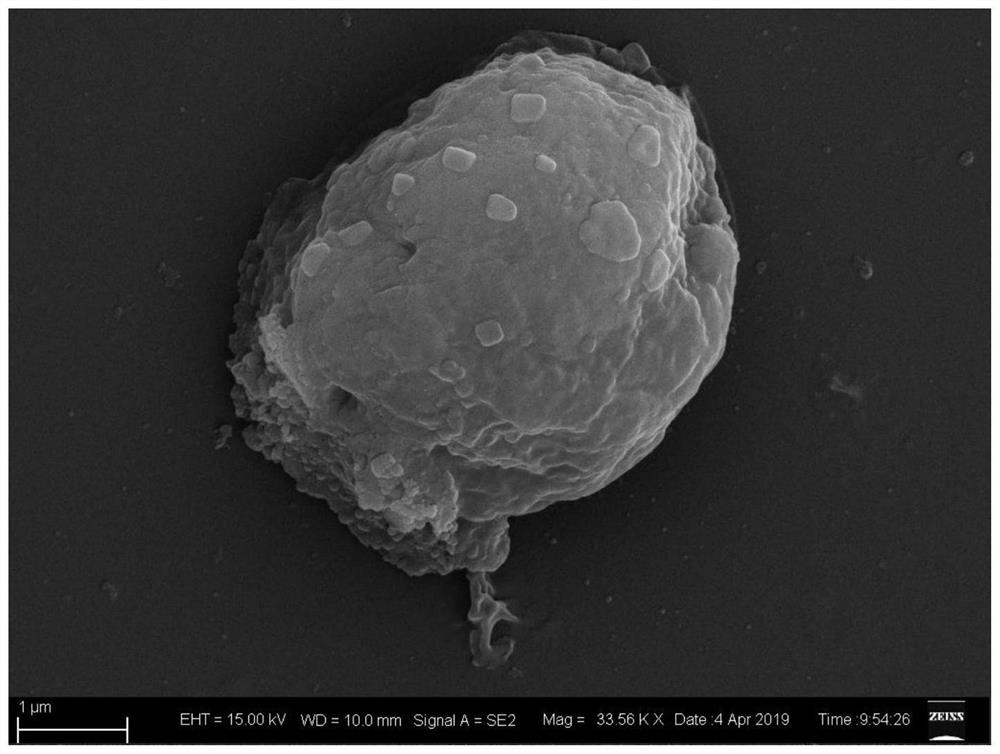

[0021] Embodiment 1: A method for realizing efficient hydrogen production based on Chlorella cell biomineralization of the present embodiment is specifically carried out according to the following steps:

[0022] 1. Using Chlorella pyrenoidosa as the substrate, use BG-11 medium to cultivate in a light incubator with a temperature of 25-30 °C for 1200-4800 LUX of continuous light. When the number of Chlorella pyrenoidosa cells reaches the logarithmic growth phase time to use;

[0023] 2. Wash the Chlorella pyrenoidosa cells first with sodium chloride solution, then with deionized water for 3 to 5 times, and collect by centrifugation to obtain the cleaned Chlorella pyrenoidea cells; Dissolving ammonium chloride in deionized water to obtain a polydiallyldimethylammonium chloride solution, adding the cleaned Chlorella pyrenoidosa cells dropwise, and stirring at a speed of 600-800 rpm for 30-40 min; using Washing with deionized water for 3 to 5 times, and collecting by centrifugat...

specific Embodiment approach 2

[0028]Embodiment 2: The difference between this embodiment and Embodiment 1 is that the concentration of the sodium chloride solution described in step 2 is 0.02 mol / L. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the concentration of the polydiallyldimethylammonium chloride solution in step 2 is 4-6 mg / mL. Other steps and parameters are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com