Low-cost ultra-wide automobile shell plate and preparation method thereof

A low-cost, wide-width technology, applied in the field of steel production and manufacturing, can solve the problems of unreasonable interaction between plate shape and process system, great difficulty brought by the process control of the whole process, and low thermal deformation resistance, so as to avoid normal Stable operation, improved market competitiveness, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

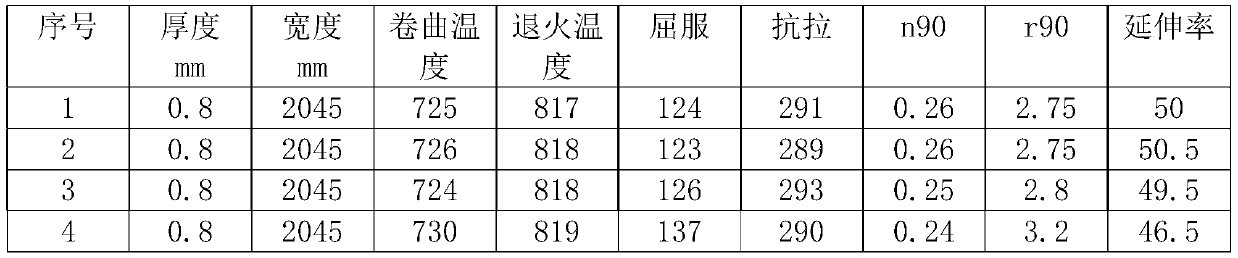

[0019] Embodiment: Taking the production of a conventional ultra-wide outer plate produced by a cold rolling plant of Benxi Iron and Steel as an example, the steel type DC06, the specification 0.8mm*2045mm, the production method of the present invention is illustrated.

[0020] A low-cost ultra-wide automobile outer plate, according to the composition weight percentage, the chemical composition of the control steel plate is: C: 0.0012%, Si: 9 0.01%, Mn: 0.1%, P: 0.008%, S: 0.009%, N: 0.0011, Ti: 0.06%, Nb: 0.005%, Als: 0.043%, and the balance is and other trace elements.

[0021] The above-mentioned preparation method of a low-cost ultra-wide automobile outer panel comprises the following steps:

[0022] Steelmaking process:

[0023] The blast furnace is used to provide high-quality molten iron, and the molten iron is pretreated for desulfurization. In order to obtain molten steel with moderate oxygen content in converter smelting, converter reblowing technology is adopted. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com