Double-hook tightener inspection and maintenance test device and use method

A technology of double hook thread tensioner and test device, which is applied in the direction of measuring device, testing of machine/structural parts, instruments, etc., can solve the problems of lack of mechanical test function, uneven oiling, large workload, etc., to improve efficiency And the effect of quality, saving manpower and material resources, easy operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

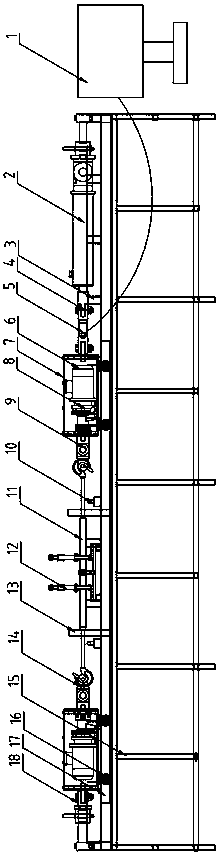

[0017] In the figure: 1. PC; 2. Hydraulic cylinder; 3. Cylinder bracket; 4. Piston rod connector; 5. Tension sensor; 6. Motor; 7. Moving seat; 8. Reducer; 10. Fuel injector; 11. Double hook tensioner; 12. Pipe vise; 13. Wire brush; 14. Hook; 15. Rack; 16. Roller; 17. Track groove; 18. External connection block.

[0018] Such as figure 1 A kind of inspection and maintenance test device for double hook thread tensioner is shown, which includes a frame, a fixing device, and a screw rotating device. A platform is installed on the upper surface of the frame, and the fixing device is fixedly installed on the platform, and the Two screw rotating devices are installed symmetrically on the left and right sides of the rod rotating device;

[0019] The fixing device includes two pipe vises symmetrically installed on the platform. The two pipe vises are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com