Power device and preparation method thereof

A technology for power devices and light modulation, which can be used in electrical components, cold cathode manufacturing, electrode system manufacturing, etc., and can solve problems such as low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

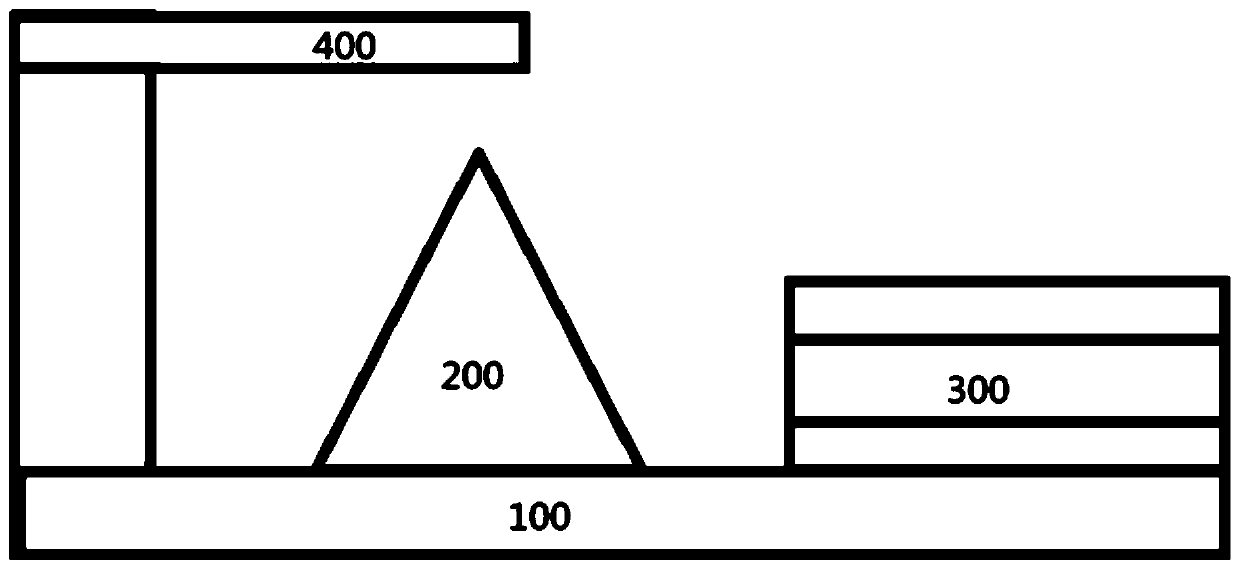

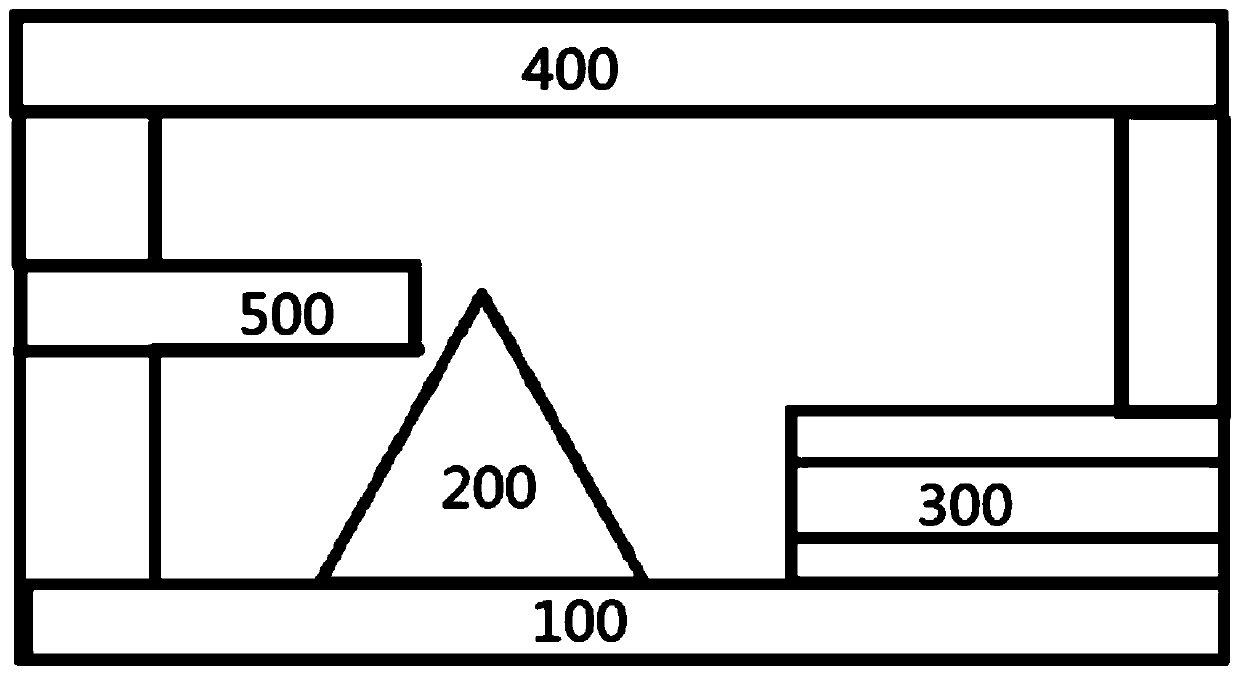

[0044] Such as figure 1 As shown, the present application provides a power device through an embodiment, including at least one vacuum-packaged unit structure; wherein, the unit structure includes:

[0045] Silicon substrate 100;

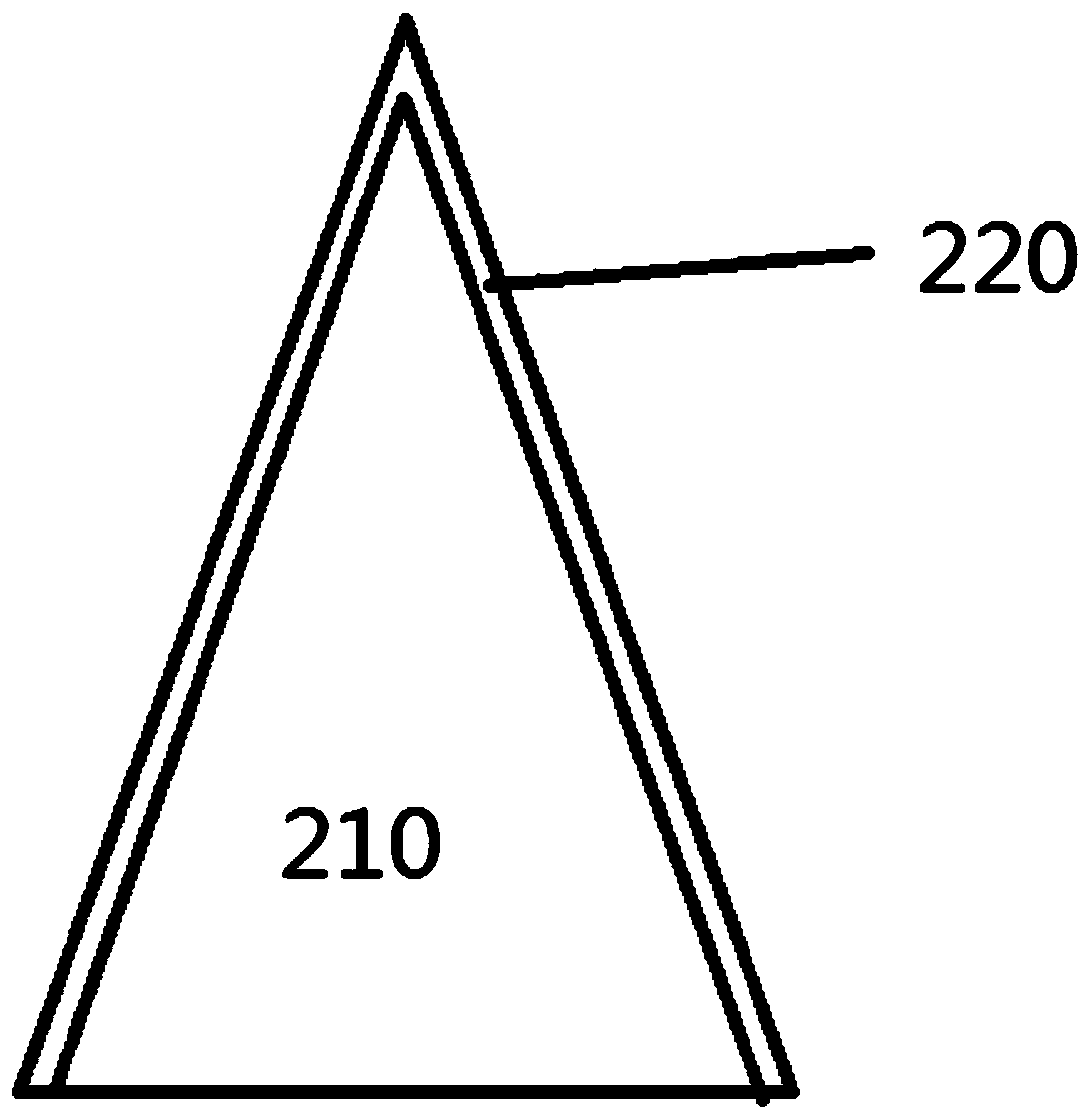

[0046] Forming the emitter 200 on the silicon substrate 100 using a silicon-based process;

[0047] A light modulator 300 formed on the silicon substrate 100 by a silicon-based process, the light modulator 300 is used to generate photons to excite the emitter 200 to emit electrons;

[0048] The collector 400 is formed on the silicon substrate 100 by using a silicon-based process, and the collector 400 is used to excite and receive electrons emitted by the emitter 200 .

[0049] It should be noted that the power device of this embodiment generally includes a plurality of integrated unit structures, and the internal structure of a single unit structure is firstly described here.

[0050] see figure 1, the silicon substrate 100 is located at the bo...

Embodiment 2

[0073] Based on the same inventive concept as in Embodiment 1, see Figure 5 , this embodiment provides a method for preparing a power device, the method is used to prepare the unit structure in Embodiment 1; the method includes:

[0074] S102, preparing and obtaining a silicon substrate;

[0075] S104. Epitaxially prepare an optical modulation electrode on a silicon substrate, the negative electrode of the optical modulation electrode is connected to the silicon substrate, and the positive electrode of the optical modulation electrode is drawn out as an optical modulation control electrode;

[0076] S106. Prepare an emitter on the silicon substrate next to the light modulation electrode;

[0077] S108 , combining the prepared collector with the silicon substrate through a silicon wafer bonding process to form a unit structure.

[0078] It should be noted that, for the specific implementation manner of this embodiment, please refer to Embodiment 1, which will not be repeated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com