Improved bearing disc and bearing device

An improved technology for carrying trays, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as pollution and affecting processing effects, and achieve pollution and damage avoidance, simple structure, and obvious effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

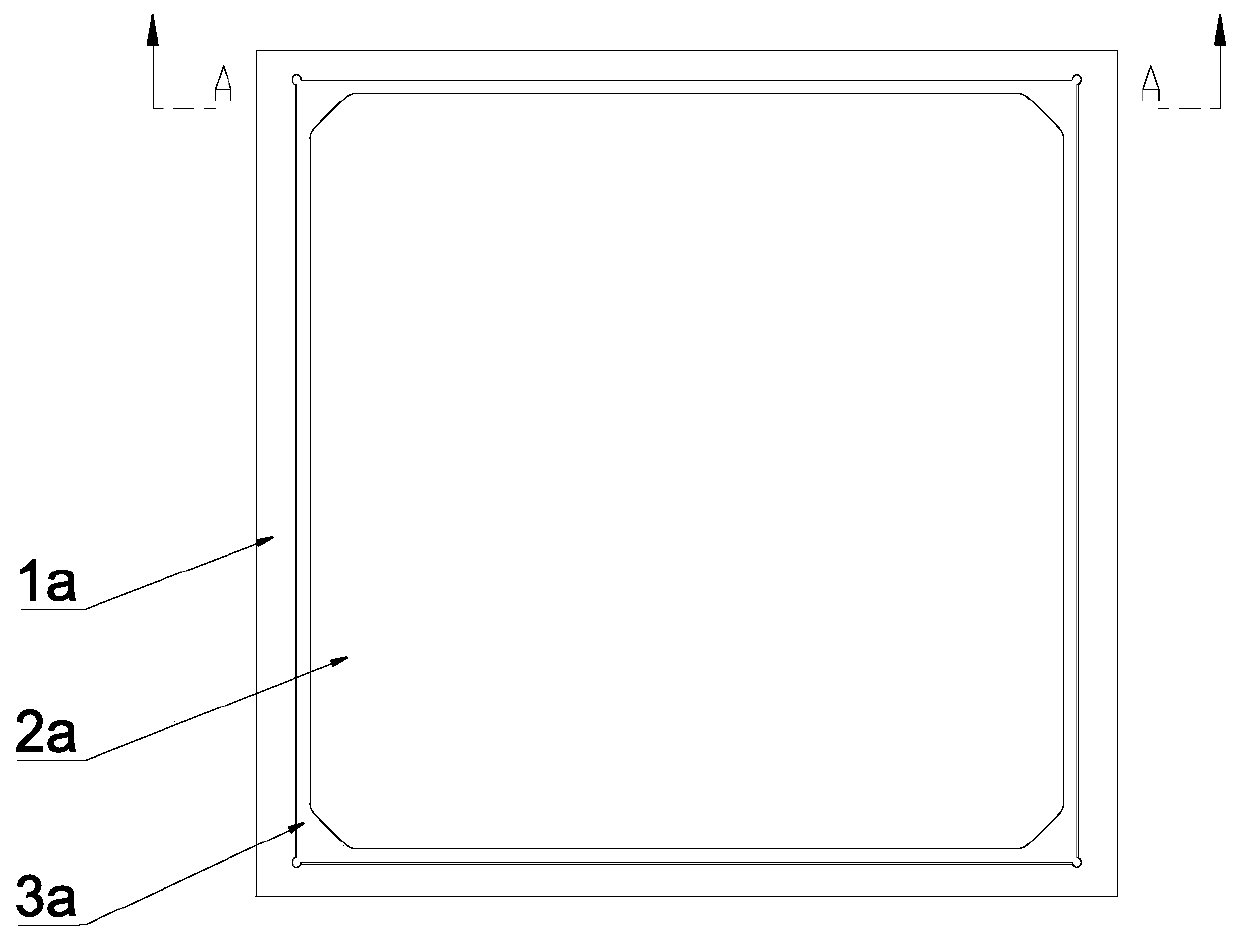

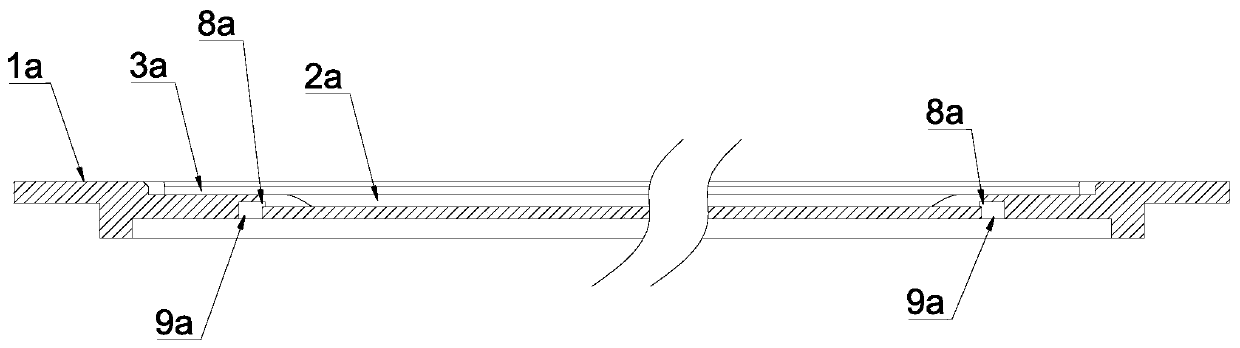

[0026] see Figure 1-Figure 5 , the improved carrying tray of this embodiment includes a main body plate 1a and a limiting member for matching and installing with the bearing frame; wherein, the limiting member is arranged on the bottom surface of the main body plate 1a, and the outer The contour is set corresponding to the inner contour of the bearing groove 15 on the bearing frame; the storage groove 2a is provided with a right-angle vent hole 10a, and the right-angle vent hole 10a includes a horizontal section 8a and a vertical section 9a, and the outlet of the horizontal section 8a It is arranged on the inner wall of the storage tank 2a, and the outlet of the vertical section 9a is arranged at the bottom of the main body plate 1a. In this embodiment, the horizontal section 8a is rectangular, and the vertical section 9a is oblong.

[0027] see Figure 4 with Figure 5 , The corners of the storage tank 2a are provided with chamfers 5a. Through the setting of the chamfer 5...

Embodiment 2

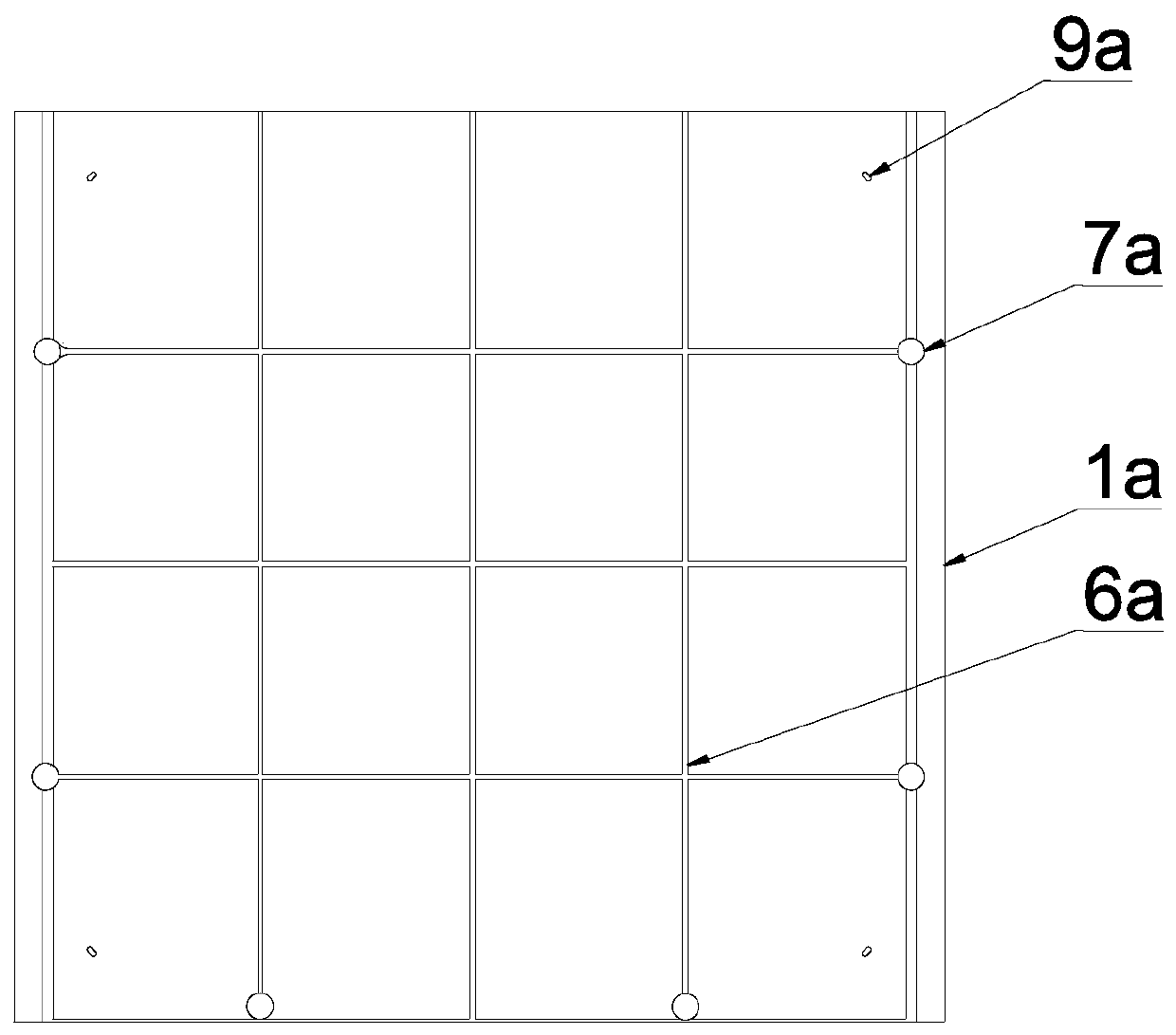

[0040] see Figure 6-Figure 9 The difference between the improved carrying tray of this embodiment and Embodiment 1 is that the width of the main body plate 1a is set corresponding to the lateral dimension of the carrying frame, and the main body plate 1a is provided with a plurality of storage slots 2a As well as the access slot 3a, the plurality of storage slots 2a and the access slot 3a are arranged along the transverse direction, and the plurality of storage slots 2a are all provided with the right-angled ventilation holes 10a. By arranging a plurality of storage slots 2a on the main body plate 1a, multiple silicon chips can be loaded, which simplifies the installation process of the carrier plate and facilitates the operation; meanwhile, the width of the main body plate 1a matches the lateral width of the carrier frame to form a rectangle or The elongated carrier plate is convenient for plate selection during processing, and there is no need to cut the plate into a single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com