Magnetic type robot charging pile and robot charging system

A technology of charging piles and robots, which is applied in battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of robot charging interface contact failure, increased cost and system complexity, and inaccurate positioning, so as to avoid undocking , Easy to promote and use, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

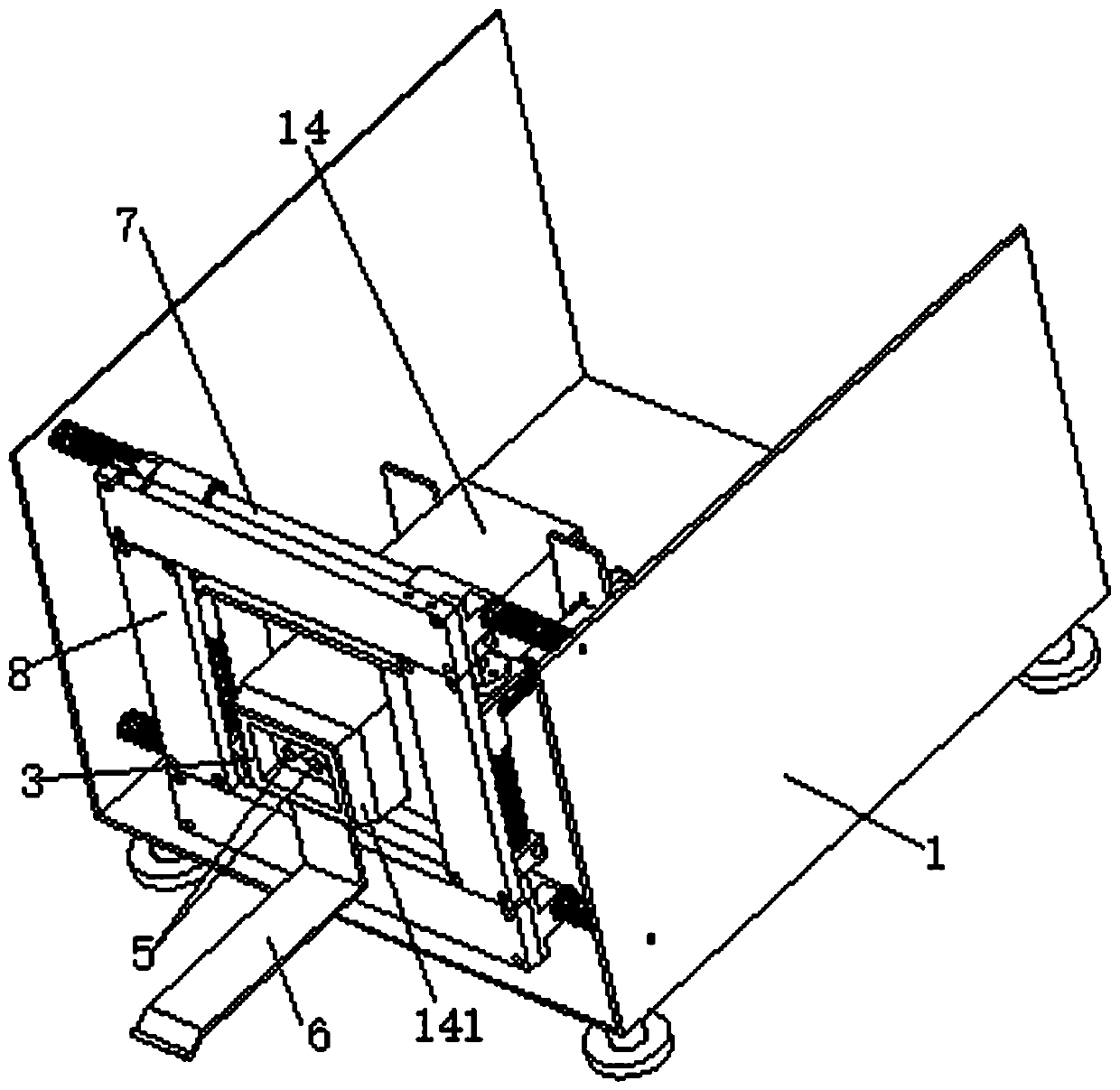

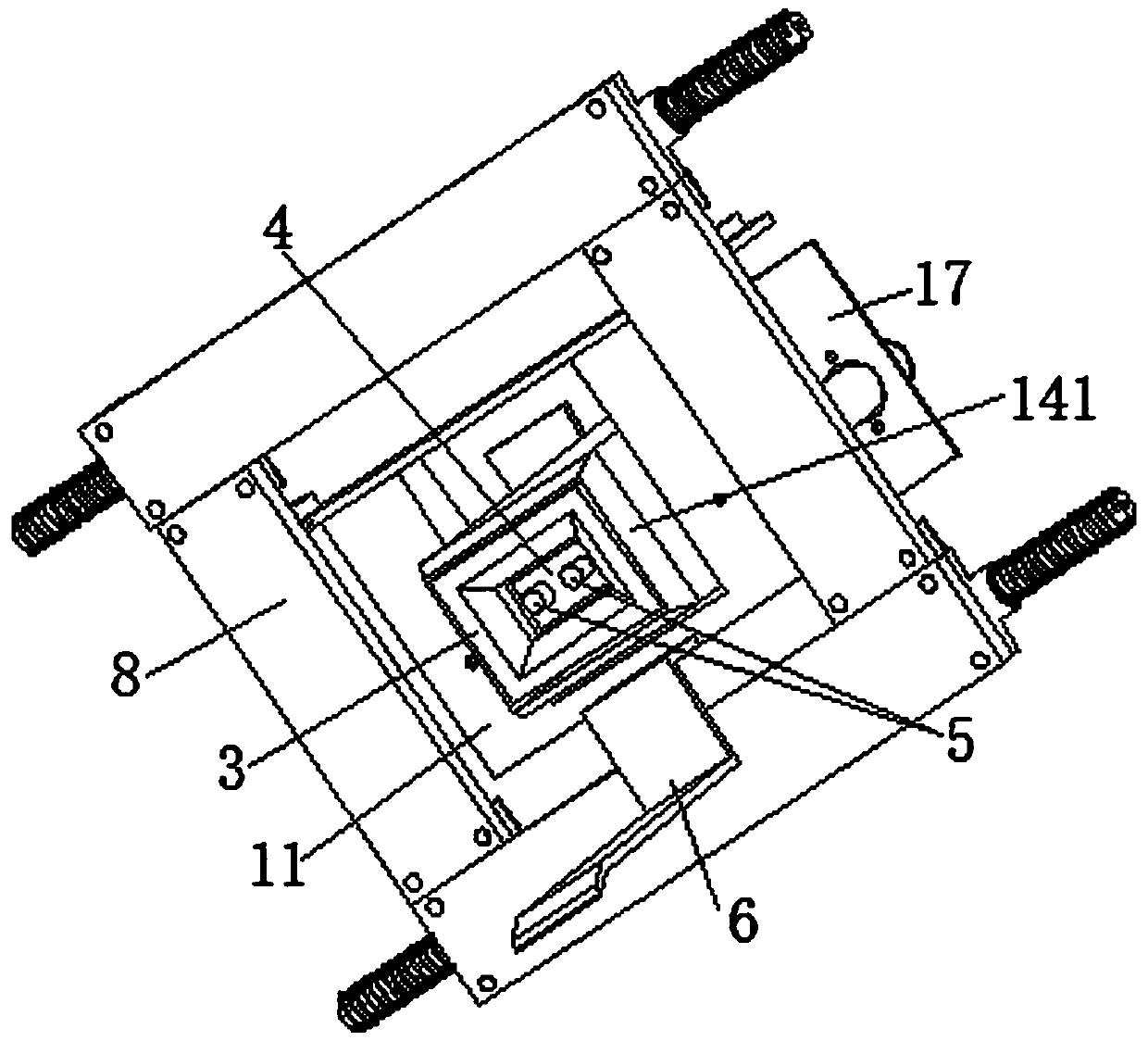

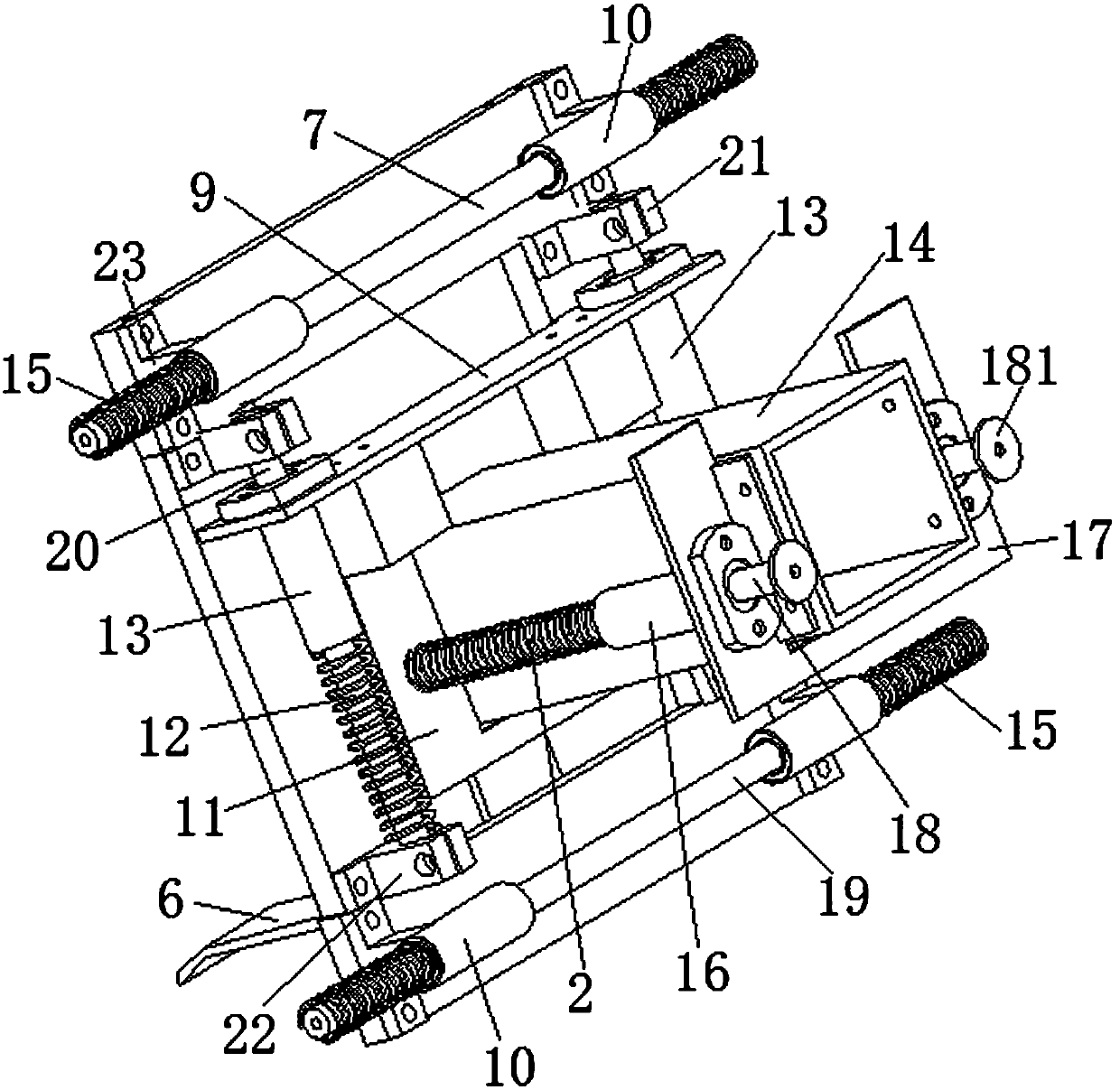

[0031] This embodiment provides a magnetic suction robot charging pile, such as Figure 1-3 As shown, charge the robot. The magnetic suction robot charging pile includes a housing 1. For the convenience of viewing the figure, only part of the housing 1 is shown in the figure. A pressing mechanism and a charging power supply module (not marked in the figure) are provided in the housing. The pressing mechanism is used to couple the charging connector with the charging power supply module after being squeezed and triggered by the charging connector of the robot. The charging power supply module is used to provide charging for the robot after the pressing mechanism is coupled by the charging connector of the robot. power supply.

[0032] In this example, if figure 1 with 2 As shown, the pressing mechanism at least includes a charging pile magnet 3 and a charging pile contact 5 fixed on the charging pile magnet, and the charging pile contact 5 includes two contacts of a positive...

Embodiment 2

[0045] This embodiment provides a robot charging system, such as Figure 4 As shown, a robot is included, and the robot includes a main controller, a rechargeable battery, a navigation module and a charging joint 24, the charging joint 24 is electrically connected to the rechargeable battery, and the rechargeable battery and the navigation module are all electrically connected to the main controller, and also includes In the above-mentioned magnetic suction robot charging pile, the charging connector 24 is provided with a charging connector magnet 25 opposite to the magnetic pole of the charging pile magnet 3, and the charging connector magnet 25 is provided with a charging connector magnet 25 that matches the charging pile contact 5. When charging, the positive pole and the negative pole on the charging joint magnet 25 correspond to the positive pole and the negative pole of the charging pile contact 5 respectively.

[0046] Further, the robot also includes a power monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com