Gas-liquid separator for separating at least one liquid component from gaseous component

A gas-liquid separator, liquid technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve problems such as component separation, and achieve the effect of improving efficiency, saving costs, and reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

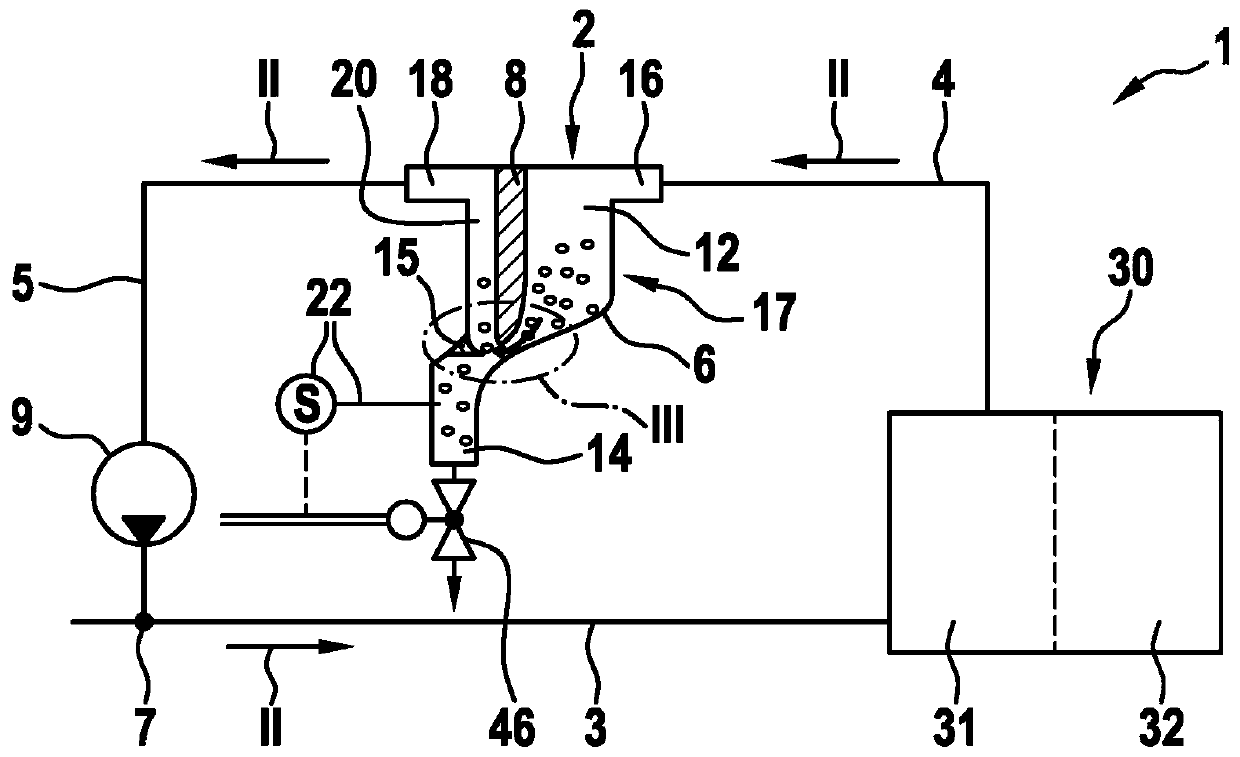

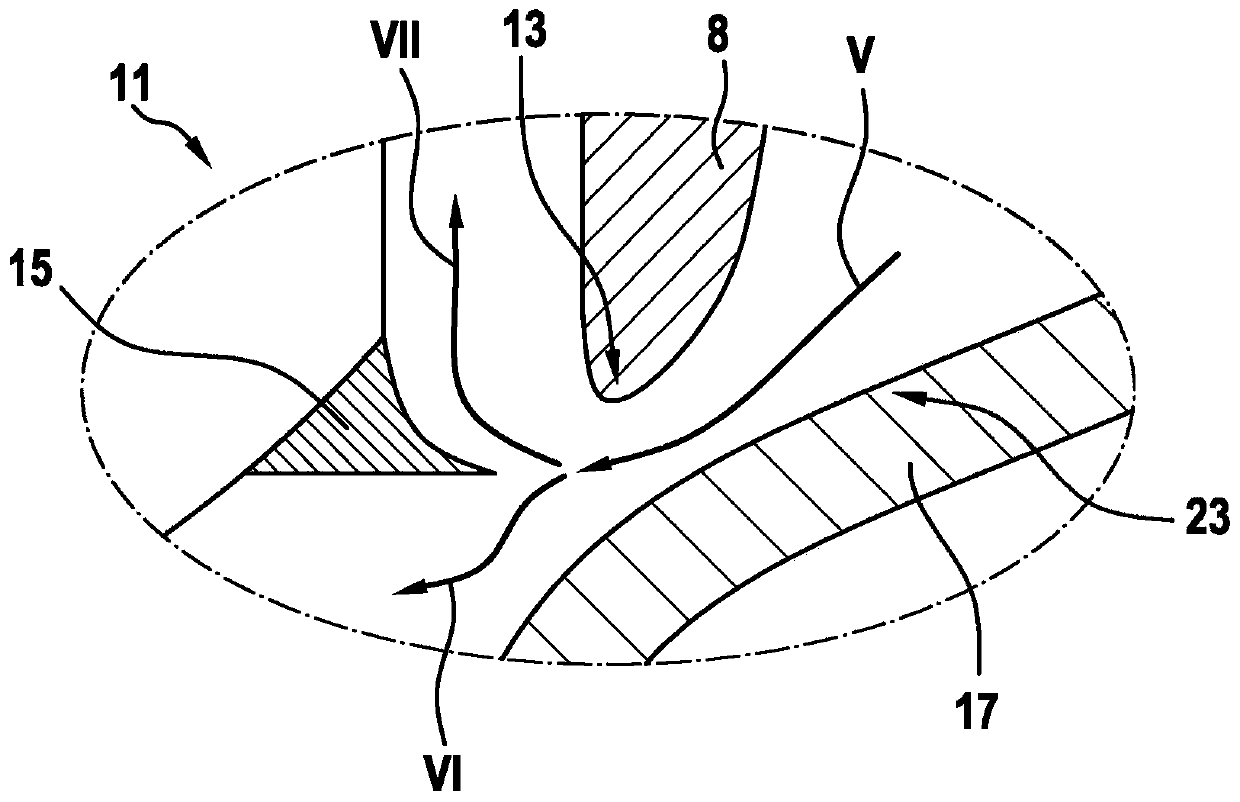

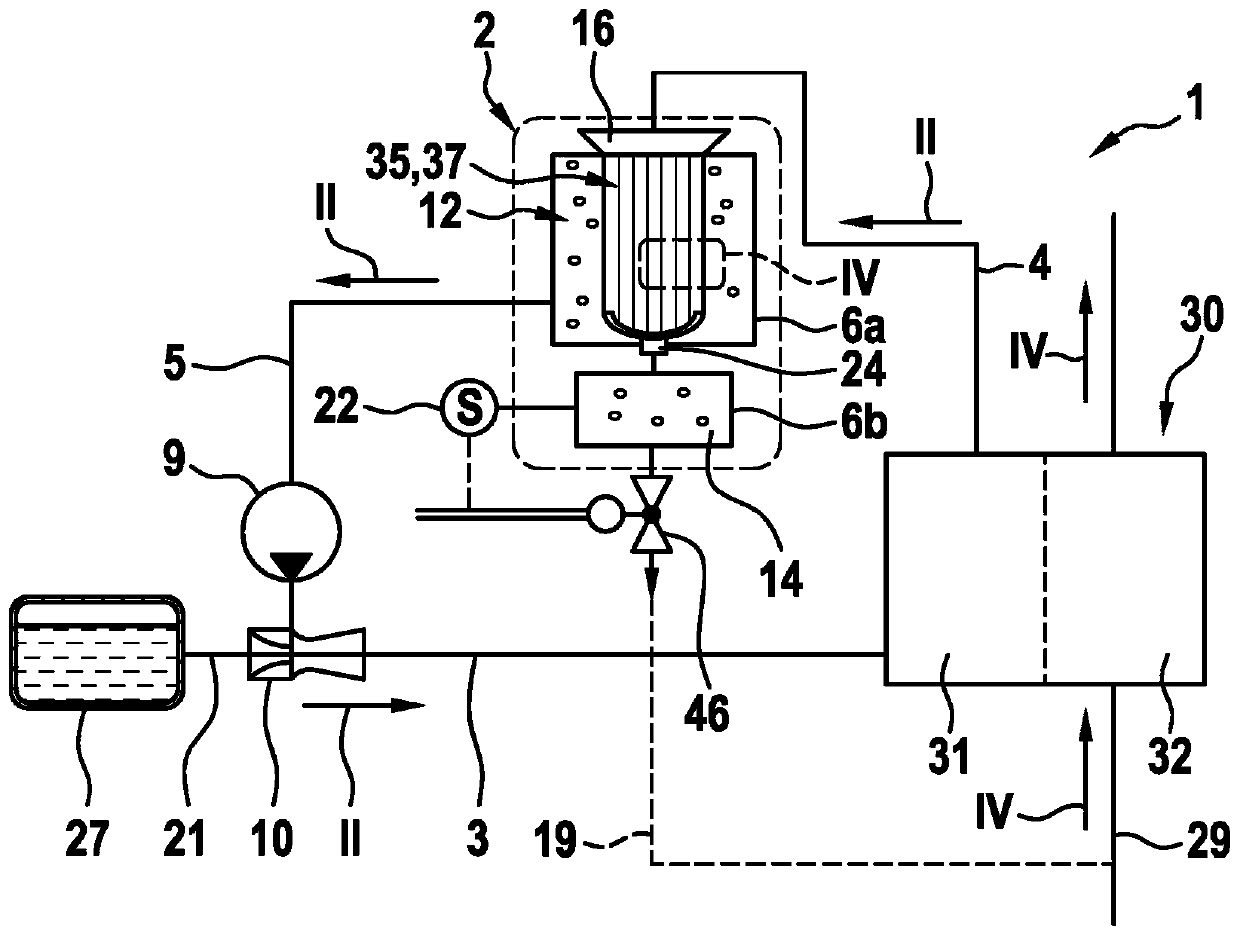

[0022] according to figure 1 and figure 2 The diagram of shows a fuel cell system 1 with a first embodiment of a gas-liquid separator 2 according to the invention, wherein the gas-liquid separator 2 removes liquid components, especially H 2 O addition to the gaseous component N 2 Separate from medium. Here, component H 2 O and N 2 By means of the centrifugal principle and the medium, especially the component H of the medium 2 The separation is carried out by means of the gas-liquid separator 2 according to the invention.

[0023] exist figure 1 shows a fuel cell system 1 in which a fuel cell 30 , a gas-liquid separator 2 and an optional recirculation pump 9 are fluidically connected to one another by means of lines. The fuel cell 30 has an anode region 31 and a cathode region 32 and is used, in particular in vehicles, to 2 and oxygen, ie O 2 reaction to generate energy. Here, energy can be generated in the form of electrical energy. In this case, the gas-liquid sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com