Sea cucumber treatment equipment

A technology for processing equipment and sea cucumbers, which is applied to fish workbenches, slaughtering, and processing fish, etc., can solve the problems of unclean removal of sediment inside sea cucumbers, lowering the grade and quality of sea cucumber products, and autolysis of sea cucumbers. Large range of speed and size, preventing the effect of cutting out of place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

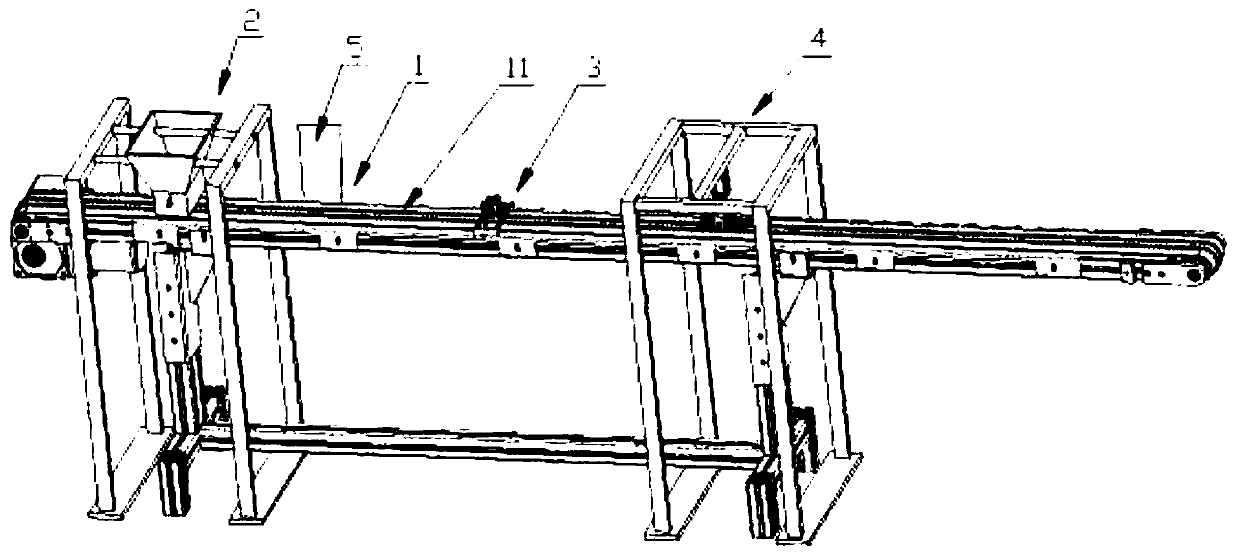

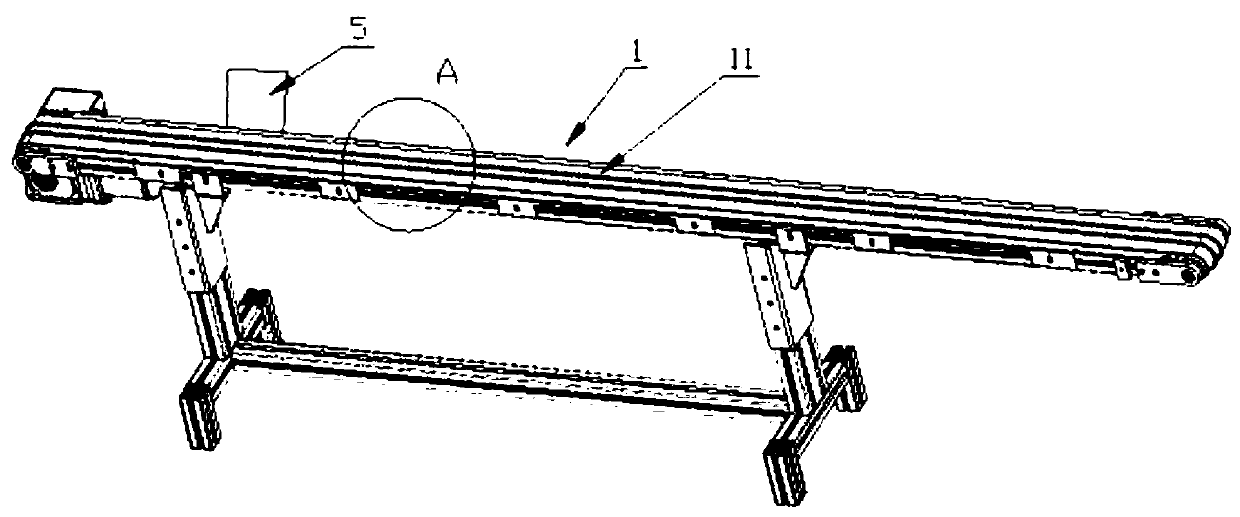

[0059] see Figure 1 to Figure 3 , the present invention is a sea cucumber processing equipment, comprising a conveying mechanism 1, the conveying mechanism 1 includes a left end, a middle part and a right end, the left end of the conveying mechanism 1 is provided with a discharge mechanism 2, and the right end of the conveying mechanism 1 is provided with a viscera processing mechanism 4 , the viscera processing mechanism 4 includes a pressing assembly 41 and a cutting assembly 42 , and the cutting assembly 42 is arranged on the pressing assembly 41 .

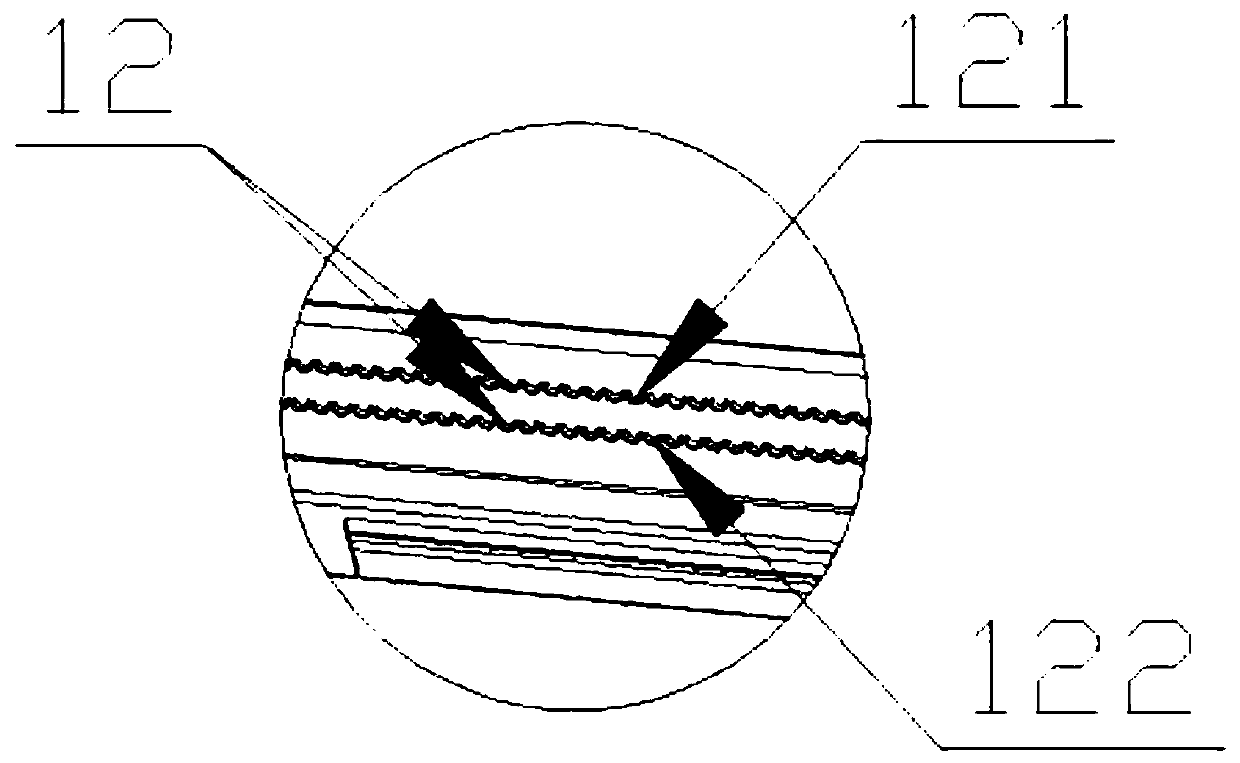

[0060] The conveying mechanism 1 is a belt conveyor, the conveyor belt 11 is set on the frame of the conveying mechanism 1, and the lower supporting plate 12 is arranged on the conveying belt 11 of the conveying mechanism 1, and the lower supporting plate 12 is arranged in a linear array on the conveying belt, and the array Direction is parallel with conveyer belt 11 moving directions, and lower supporting plate 12 is rubber l...

Embodiment 2

[0080] Others are the same as in Embodiment 1, the difference is that the cleaning assembly is improved and does not need to be hand-held manually.

[0081] see Figure 17 : The viscera processing mechanism 4 also includes a cleaning assembly 43, and the cleaning assembly 43 is arranged between the cutting assembly 42 and the pressing assembly 41;

[0082] The cleaning assembly 43 includes a water tank 431, a steam generator 432 and a spray pipe 433. A liquid level sensor 434 is arranged in the water tank 431. A first pipeline is arranged between the water tank 431 and the steam generator 432. A high-pressure water pump 435 is arranged on the first pipeline. A pipeline is divided into two branches, wherein a steam generating device 432 is arranged on one branch, a limit temperature sensor 436 is arranged in the steam generating device 432, a second pipeline is arranged between the steam generating device 432 and the spray pipe 433, and a second pipeline is arranged on the seco...

Embodiment 3

[0085] Others are the same as in Embodiment 2, the difference is that in order to meet different customer needs, the opening on the back of the sea cucumber is reduced and a turning mechanism is added.

[0086] see Figure 8 and Figure 9 : The middle part of the conveying mechanism 1 is provided with an overturning mechanism 3, and the overturning mechanism 3 is used to control the setting of the abdomen of the sea cucumber upward. The overturning mechanism 3 includes a base 31, one end of the base 31 is fixedly arranged on the frame of the conveying mechanism 1, and the other end sticks out The frame is arranged on the upper side of the conveyor belt 11, and one end of the base 31 arranged on the frame is provided with a visual sensor 32, the visual sensor is a 3D visual sensor, model WuKong-0230B, and the visual sensor 32 is used to detect the tube feet of sea cucumbers, set A support 33 is provided on the base 31 at the upper end of the conveyor belt 11, a motor C34 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com