Discharging structure of chemical raw material breaking machine

A technology of chemical raw materials and crushers, which is applied in the direction of grain processing, etc., and can solve problems such as difficult raw material dispersal, difficult raw material diversion and transportation, and easy blockage of discharge openings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

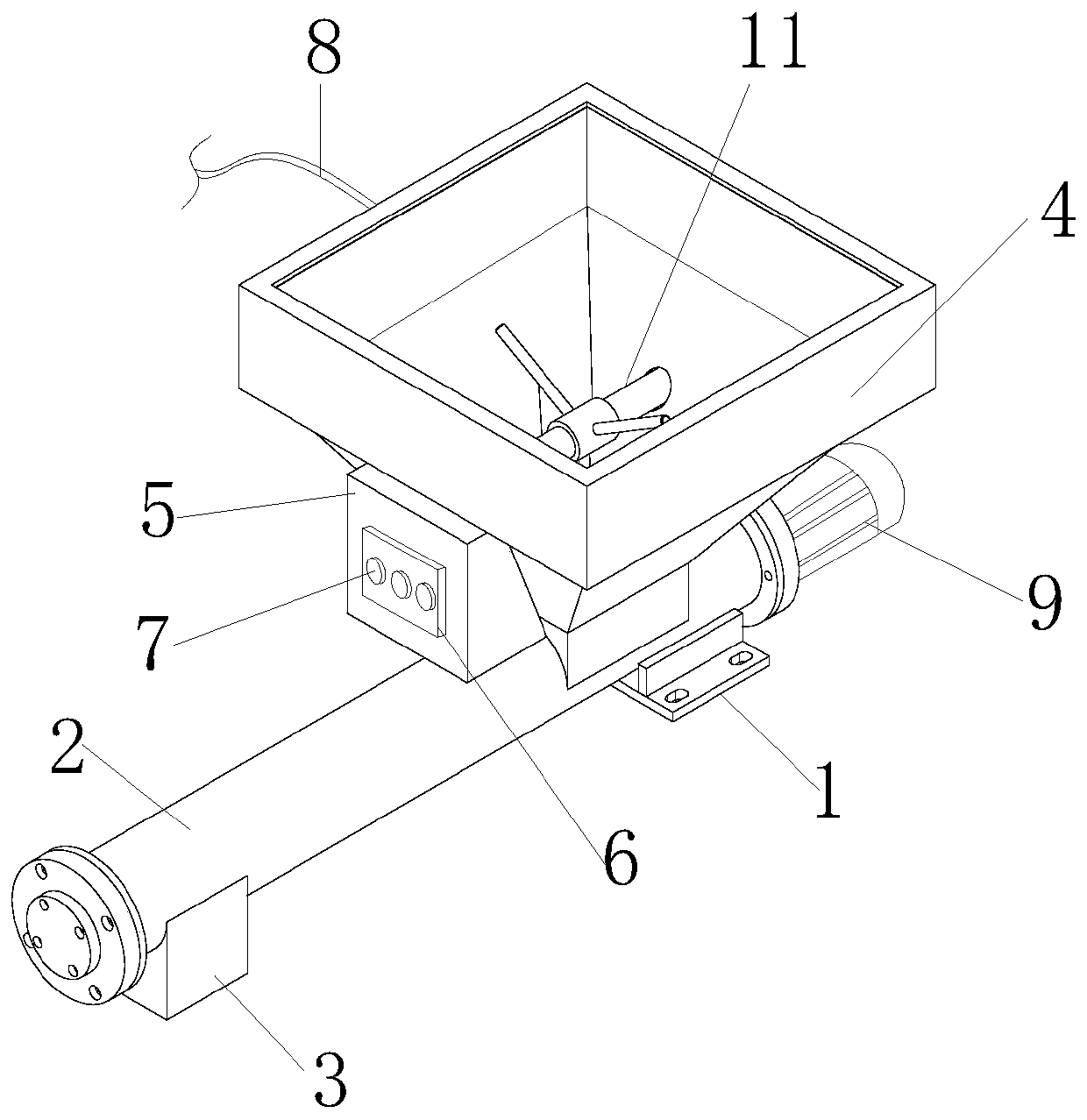

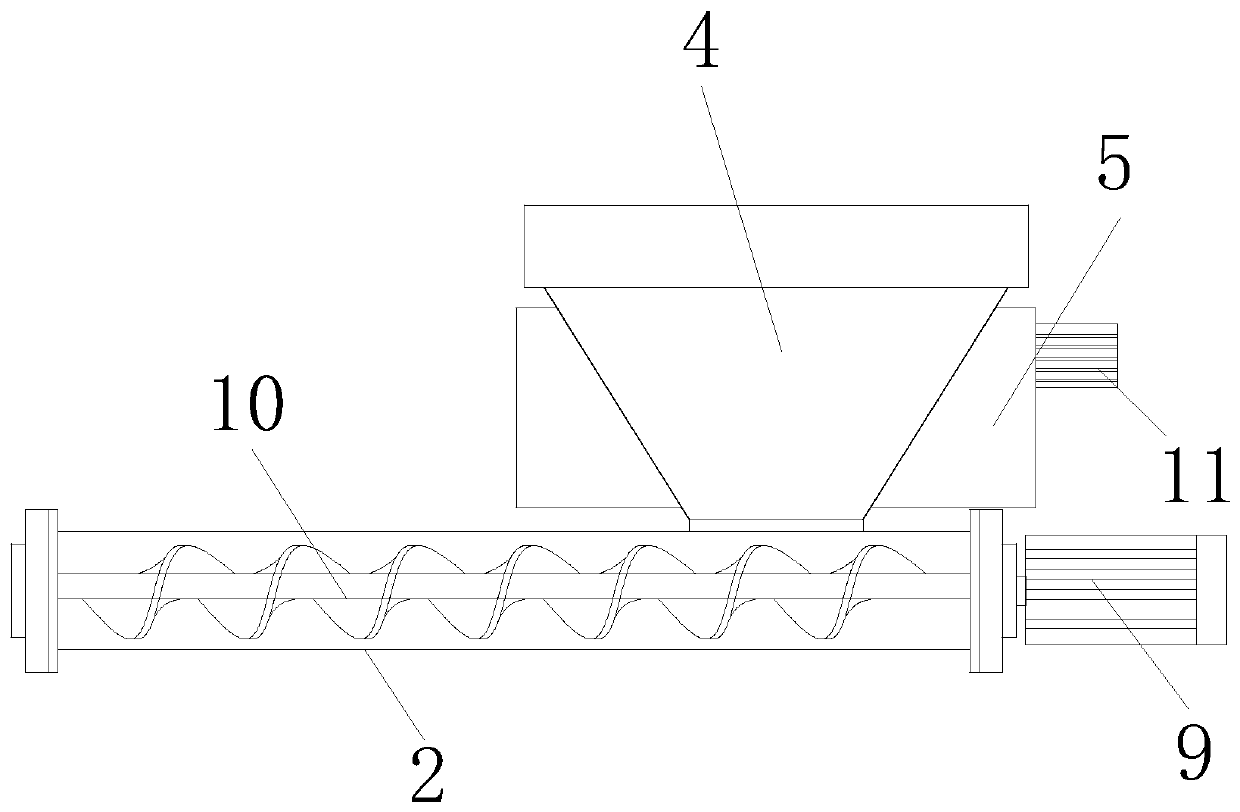

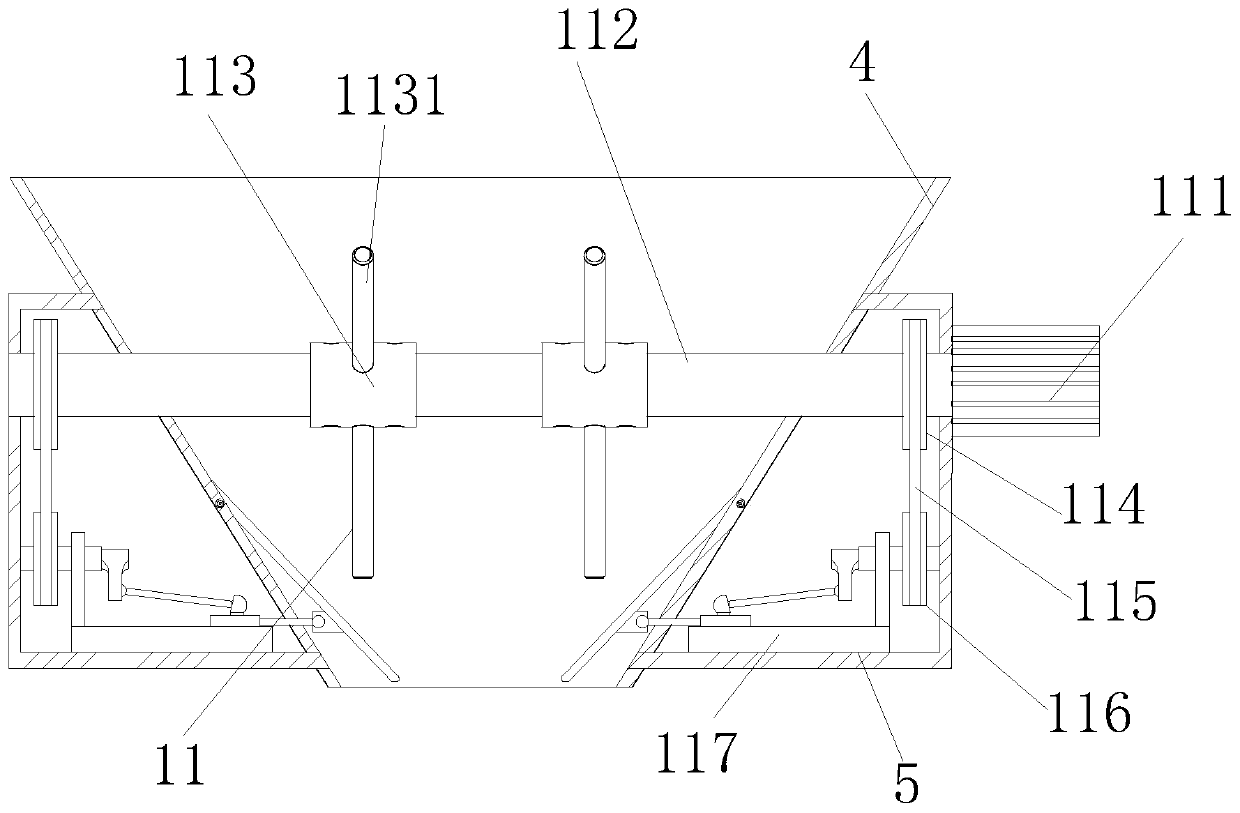

[0028] see figure 1 and figure 2 , the present invention provides a discharge structure of a chemical raw material crusher through improvement, including a base 1, a discharge cylinder 2, a discharge hopper 3, a feed hopper 4, a feeding auger 10 and a bulk feeding mechanism 11, the base 1 It is fixedly connected with the right end of the bottom of the discharge cylinder 2, the discharge cylinder 2 is seamlessly connected with the top edge of the discharge hopper 3, the discharge cylinder 2 is connected with the bottom of the feed hopper 4, and the breaking and feeding mechanism 11 is installed and fixed on the inside of the fixed frame 5, The left and right sides of the feed hopper 4 are relatively fixed with a fixed frame 5, the left end of the fixed frame 5 is provided with a control panel 6, the left end of the control panel 6 is equipped with a button 7, the rear end of the feed hopper 4 is fixed with a power wire 8, and the discharge cylinder 2 passes through the The sc...

Embodiment 2

[0032]The present invention provides a discharge structure of a chemical raw material crusher through improvement. The upper end of the breaking roller 113 is provided with a breaking rod 1131, and there are three breaking rods 1131, which are equidistantly distributed along the surface of the upper end of the breaking roller 113. Of course, the number of dispersing rods 1131 can also be more, and the specific number is designed according to the actual situation. The inner side of the fixed seat 1172 is provided with a sliding groove 11721, and the sliding seat 1175 is slidably matched with the inner side of the sliding groove 11721, which is beneficial to make the sliding The seat 1175 moves smoothly, the lower right end of the deflector 1176 is provided with a fixed block 11761, and the sliding seat 1175 is movably nested inside the fixed block 11761, the upper end of the sliding seat 1175 is provided with a movable seat 11751, and the swing rod 1174 is movably nested in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com