Wind power equipment and electrostatic dust collection device thereof

A technology of electrostatic dust removal and wind power equipment, applied in the field of air purification, which can solve the problems of reducing the flow area of the air duct, large air pressure loss, and complicated manufacturing process, and achieves good dust removal effect, reduced pressure loss, and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

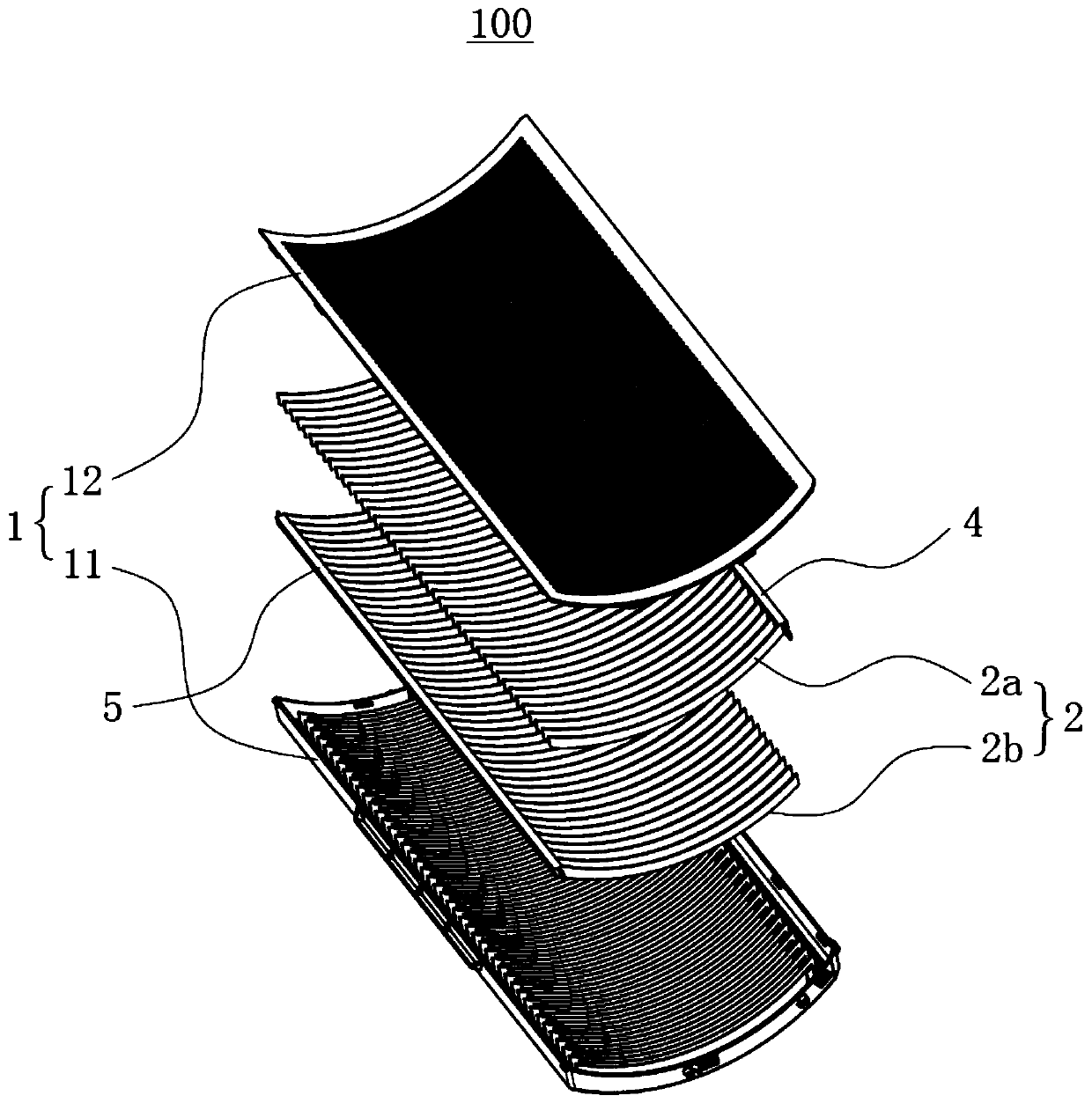

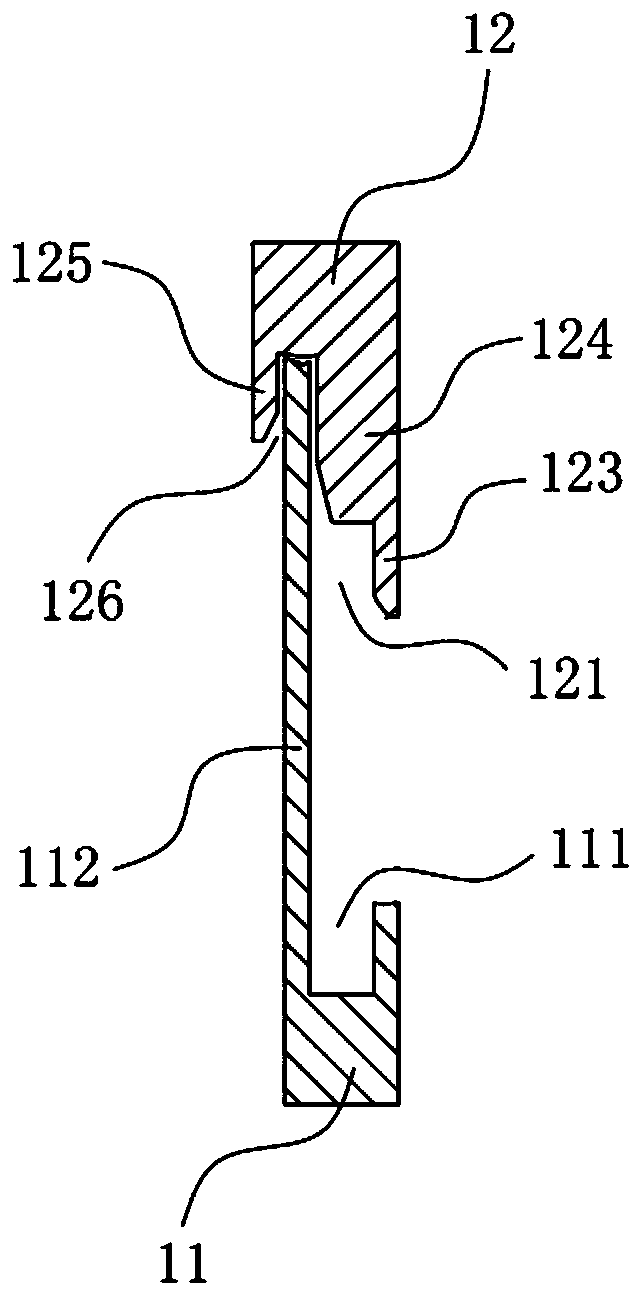

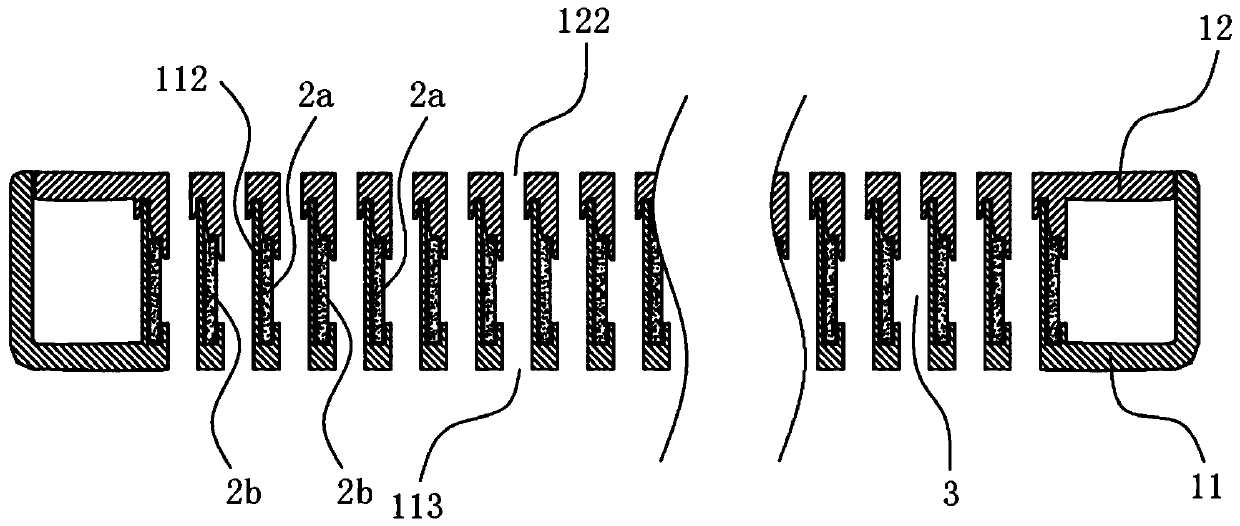

[0043] combine Figure 1 to Figure 3As shown, the embodiment of the present invention provides an electrostatic precipitator 100, which mainly includes a casing 1 and a potential plate 2 arranged in the casing 1; the casing 1 includes a first casing plate 11 and a second casing plate 12 arranged oppositely. , the surface of the first shell plate 11 facing the second shell plate 12 is provided with a first installation groove 111 , and the surface of the second shell plate 12 facing the first shell plate 11 is provided with a second installation groove corresponding to the first installation groove 111 121, the two sides of the potential plate 2 are respectively inserted into the first installation slot 111 and the second installation slot 121; the potential plate 2 is used to form an electric field, which is set to at least two pieces, and at least one of the potential plates 2 is used for connecting The positive pole of the power supply is denoted as high potential plate 2a, ...

Embodiment 2

[0059] like Figure 10 As shown, the difference between this embodiment and the first embodiment is that the insulating structure is an insulating coating 118 having a certain thickness, and the insulating coating 118 is provided on one surface of the potential plate 2 . Correspondingly, refer to image 3 It can be seen that the second shell 12 is no longer provided with the first slats 123, the second slats 125 and the third installation grooves 126, and the second installation grooves 121 are no longer composed of the first slats 123 and the insulating structure, but are replaced by What is fixed is the second installation groove 121 fixed on the second shell plate 12 . Except for the above differences, other specific structures of the embodiment of the present invention are the same as those in the first embodiment, and the corresponding principles and technical effects are also the same, which will not be repeated here.

[0060] To sum up, the present invention provides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com