Vacuum laser welding device

A laser welding and vacuum technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of easy deformation and cracking of products, complex welding conditions, uneven welding, etc., to achieve simple structure, convenient welding, and uniform welding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

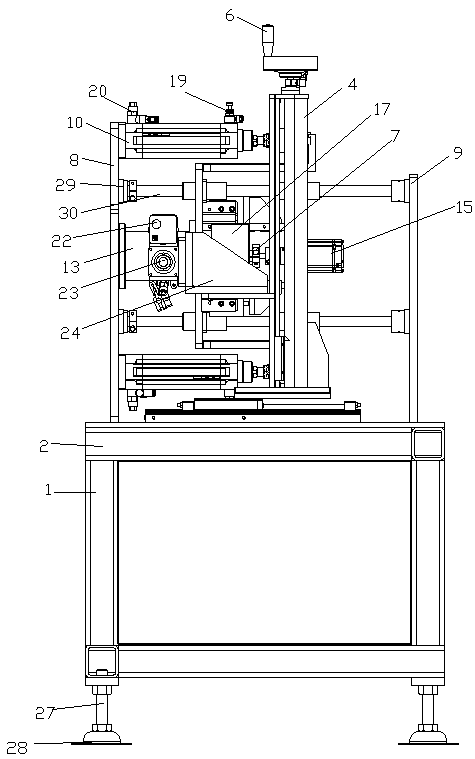

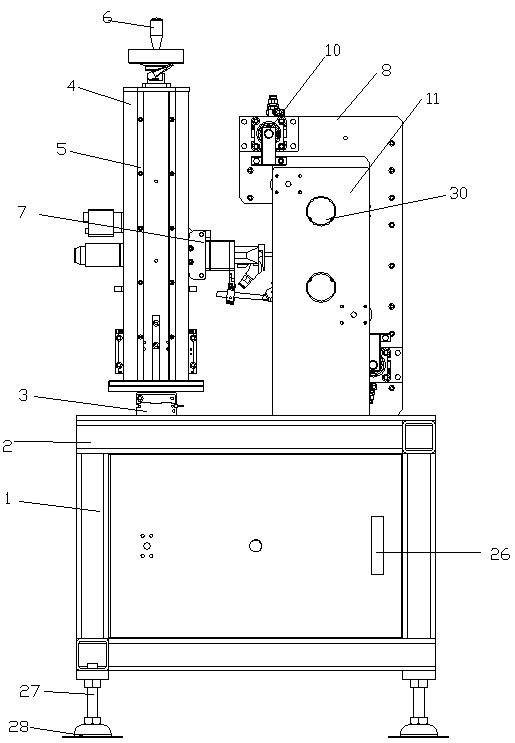

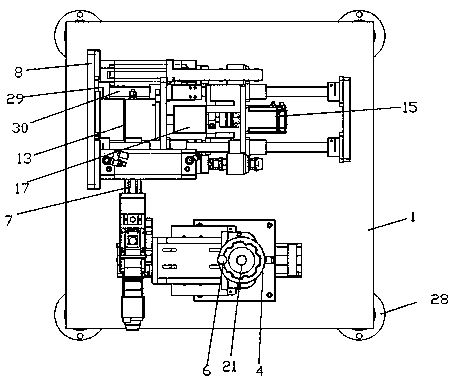

[0022] see Figure 1-4 , a vacuum laser welding device according to an embodiment of the present invention includes an equipment chassis 1, the top of the equipment chassis 1 is provided with a top plate 2, a base 3 is fixed on the top plate 2, and the base 3 is movable A Z-axis lift 4 is connected, a slide rail 5 is provided on the Z-axis lift 4, a stroke handle 6 is provided on the top of the Z-axis lift 4, a laser welding gun 7 is provided on the slide rail 5, and the top plate 2 A first fixing plate 8 and a second fixing plate 9 are arranged on the upper part, and the top and bottom ends of the first fixing plate 8 are provided with a pressure-holding cylinder 10. A first baffle 11 and a second baffle 12 are provided, a guide shaft seat 29 is arranged on the first fixed plate 8 and the second fixed plate 9, and a plurality of guide shafts 30 are arranged on the guide shaft seat 29, Several of the guide shafts 30 pass through the first baffle 11 and the second baffle 12 , ...

Embodiment 2

[0025] see Figure 1-4 , one end of the pressure maintaining cylinder 10 is fixed on the first fixing plate 8 , the first baffle 11 is provided with a support frame 18 , and one end of the support frame 18 is fixed on the pressure maintaining cylinder 10 On the other end, the pressure maintaining cylinder 10 is provided with a valve valve 19 and a safety valve 20 .

[0026] By arranging the valve valve 19 and the safety valve 20, the air pressure in the pressure-holding cylinder 10 can be pressed and released to protect the safety of the device.

Embodiment 3

[0028] see Figure 1-4 , the slide rail 5 is connected with the travel handle 6 through the rotating shaft rod 21 in a rolling connection, the vacuum box 13 is provided with a vacuum box cover 22, the vacuum box cover 22 is provided with an evacuation port 23, the second block A limiting block 24 is provided at one end of the plate 12 close to the pressing cylinder 17 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com