Method for preparing menthane carboxamide by taking L-menthol as raw material

A technology of L-menthol and menthylamide, applied in the field of preparing menthylamide, can solve the problems of high production cost and high safety risk, and achieve the effects of small safety risk, simple operation and management, and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

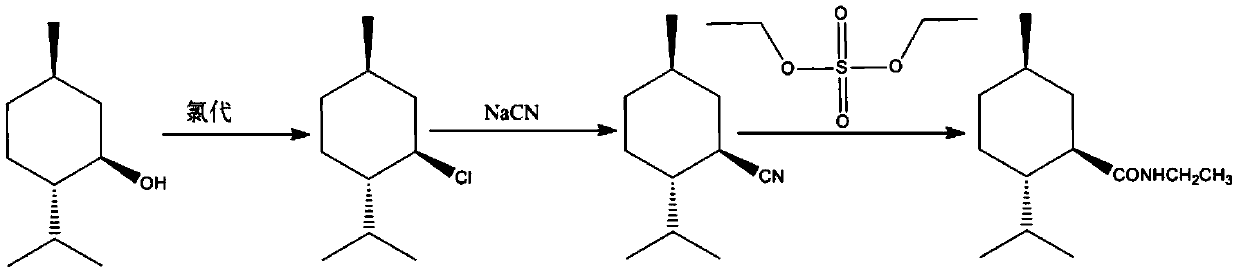

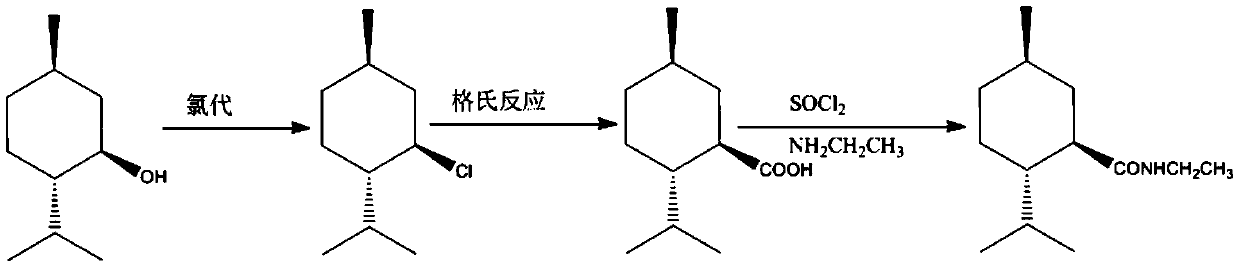

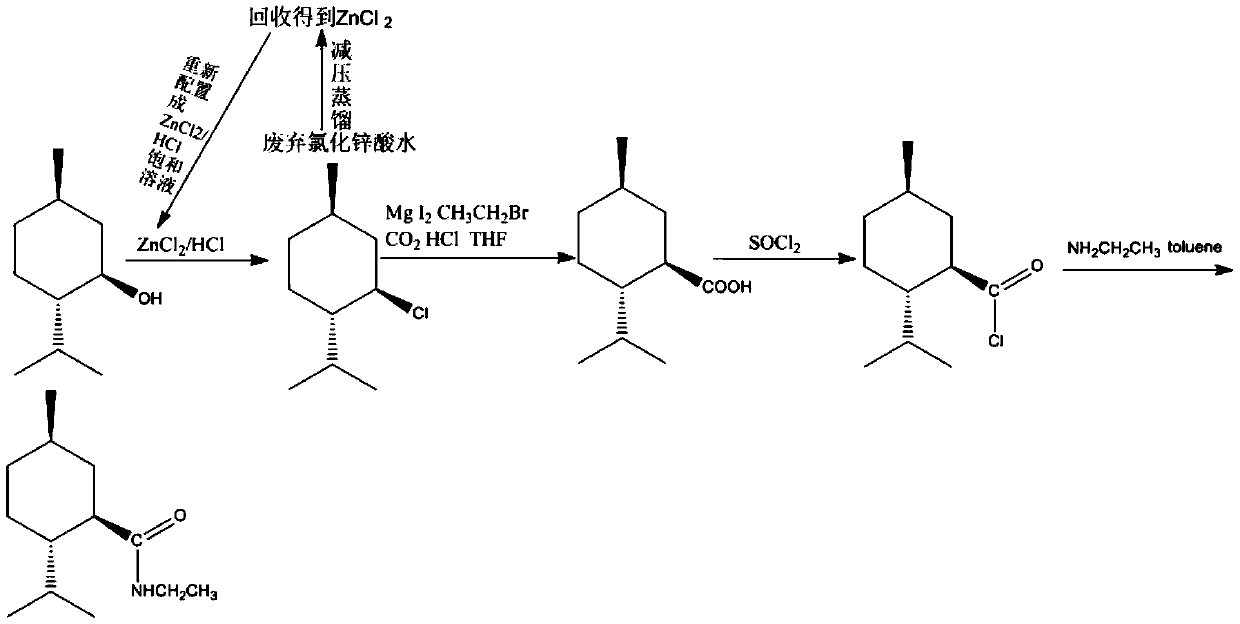

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a kind of method that takes L-menthol as raw material to prepare menthyl amide, and the preparation method comprises the following steps:

[0029] Step (1): Levomenthol and ZnCl 2 / HCl saturated solution for chlorination reaction, after the reaction, the upper oily matter is subjected to post-treatment to obtain chloromenthane, and the waste acid water in the lower layer is collected and subjected to vacuum distillation to remove H in the acid water 2 O and HCl, recovery of ZnCl 2 , the vacuum distillation is completed, and the recovered ZnCl 2 Add reagent concentrated HCl to reconstitute ZnCl 2 / HCl saturated solution, put in L-menthol and carry out the chlorination reaction again, and so on and on, realize the multiple application of waste acid water in the chlorination reaction, and the chloromenthane obtained by the reaction is used as the raw material for the next step reaction;

[0030] Step (2): Add magnesium chips, initiator, an...

Embodiment 1

[0056] The preparation method of menthyl amide (waste acid water is applied)

[0057] (1) Preparation of chloromenthane (used waste acid water)

[0058] Put the waste acid water produced after the chlorination reaction of the control group (waste acid water does not apply mechanically) into a reactor with a distillation device, heat the reactor for vacuum distillation, and control the temperature of the vacuum distillation at 80-130°C. During the distillation process, the distillation temperature must be strictly controlled. If the temperature is too high and the distillation time is too long, the zinc chloride will easily deteriorate and form basic zinc chloride, and the higher the temperature, the more serious the corrosion of the equipment caused by acid water. The vacuum degree is -0.08~-0.096Mpa, the time of vacuum distillation is 10-31h, the waste acid in the waste acid water is distilled, and zinc chloride is recovered. After the distillation, concentrated hydrochloric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com