Method for recovering technetium from post-treatment waste liquid of spent fuel

A technology for spent fuel and waste liquid, applied in the direction of improving process efficiency, etc., can solve the problems of high price, low extraction efficiency of TRPO, and difficulty in the synthesis of cup-crown reagents, etc., and achieve the effect of high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

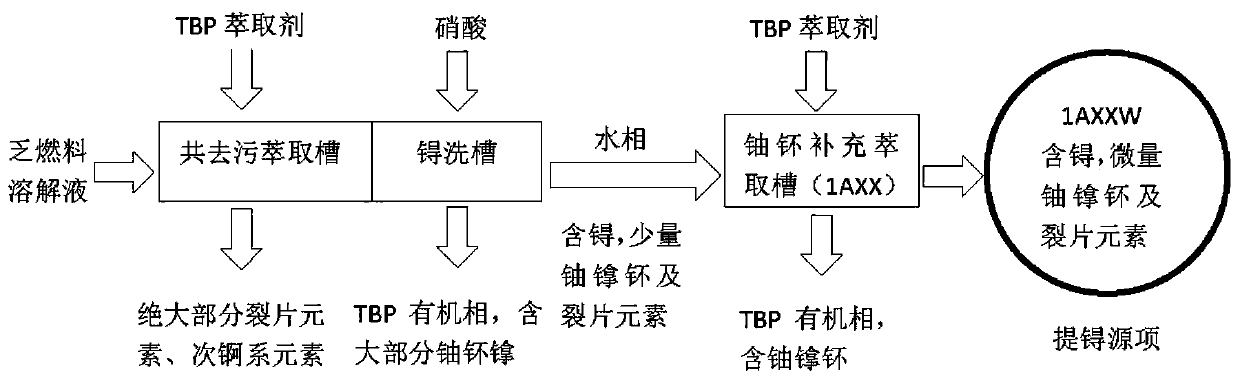

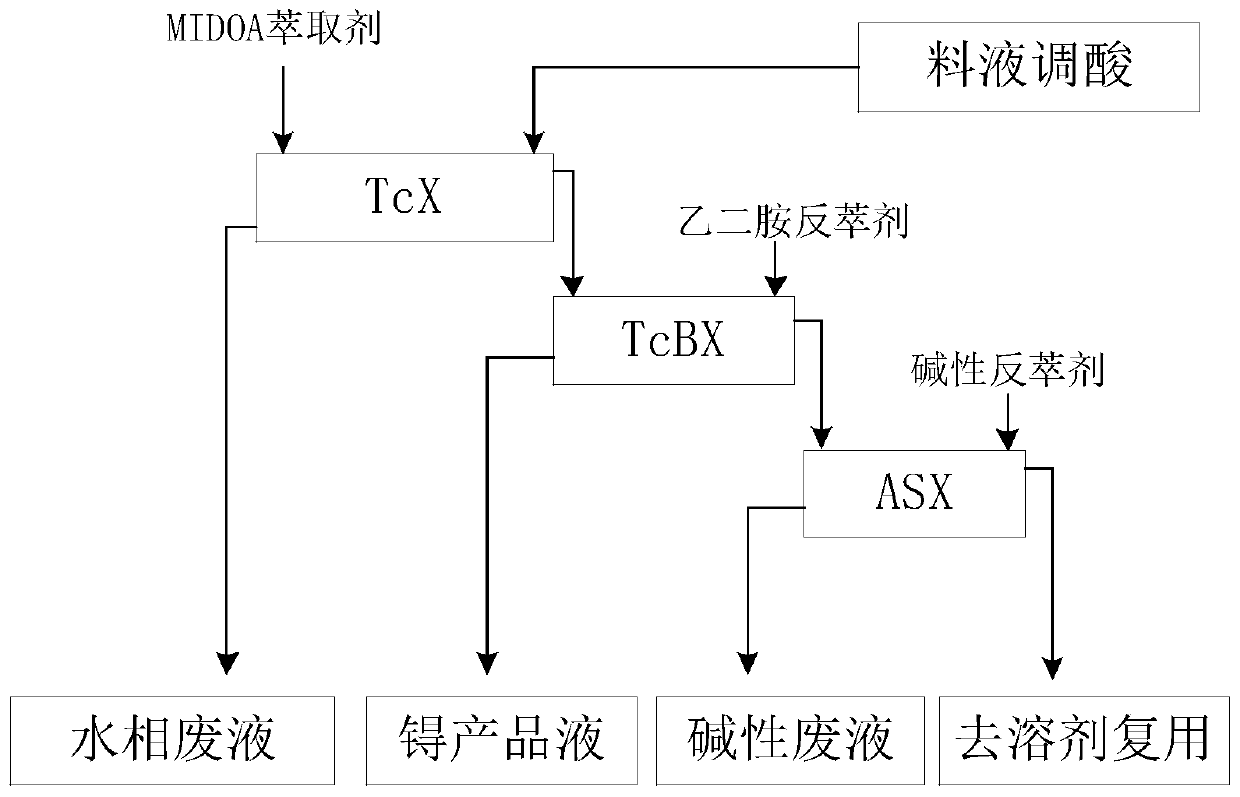

[0043] For the process of this embodiment, see image 3 .

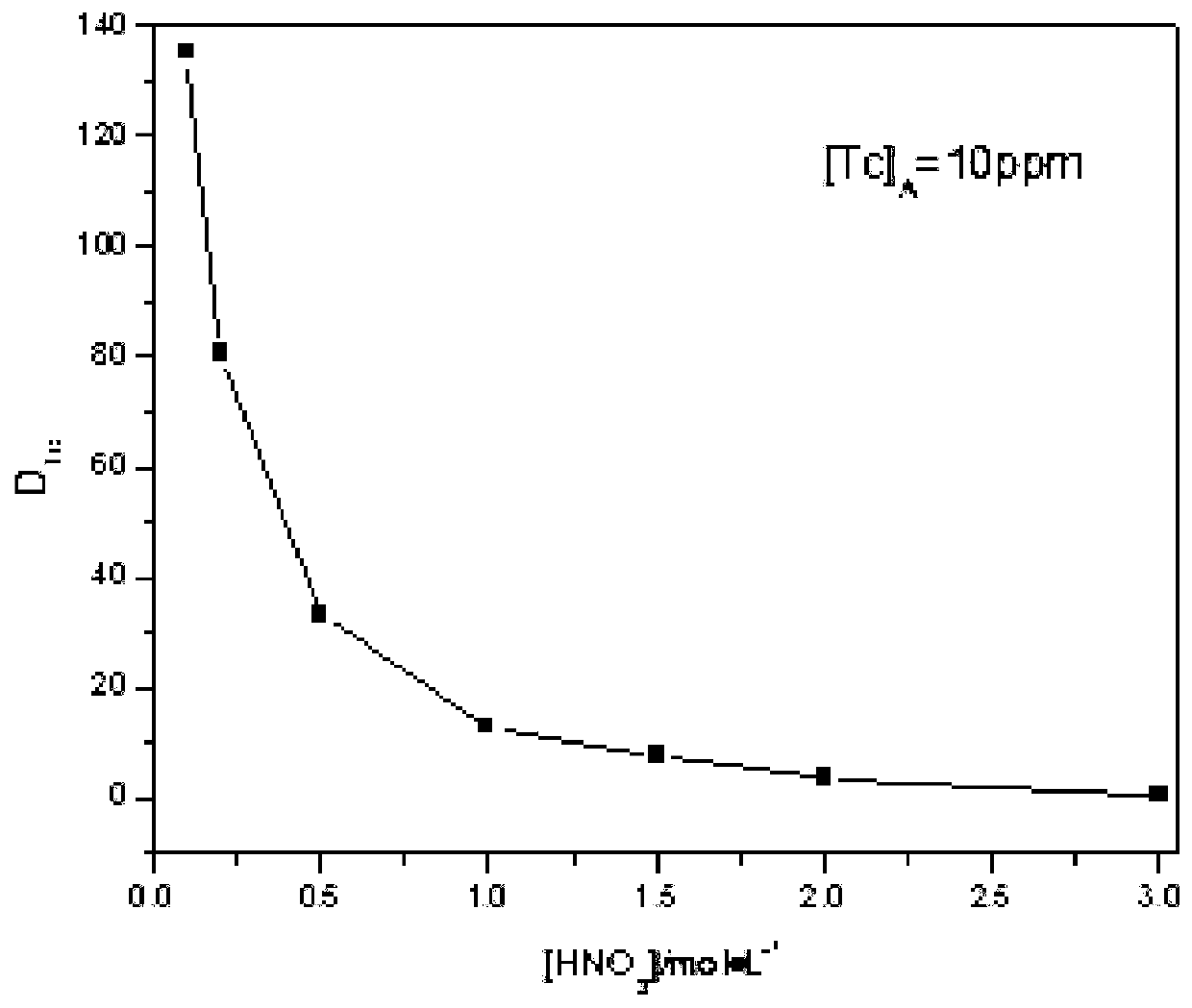

[0044] (1) Material liquid acid adjustment and technetium extraction (TcX): 0.1mol / L MIDOA is used as the extraction agent, kerosene is used as the diluent, 1AXXW is extracted after the acid adjustment to 0.5mol / L, after 6-stage extraction, technetium The recovery rate reaches above 99.99%.

[0045] (2) Technetium back-extraction (TcBX): use 0.2mol / L ethylenediamine to back-extract technetium from the extracted organic phase, and separate it from tetravalent impurity elements. After 6-stage back-extraction, the decontamination of Pu(IV) reaches 100 Above, the yield of technetium reaches 99%.

[0046] (3) An washing (ASX): wash the organic phase with 0.02mol / L ammonium carbonate solution, and the organic phase can be reused after washing.

[0047] Through the above process, the total yield of technetium reaches 99%, the decontamination of plutonium reaches more than 100%, and the decontamination of uranium reaches m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap