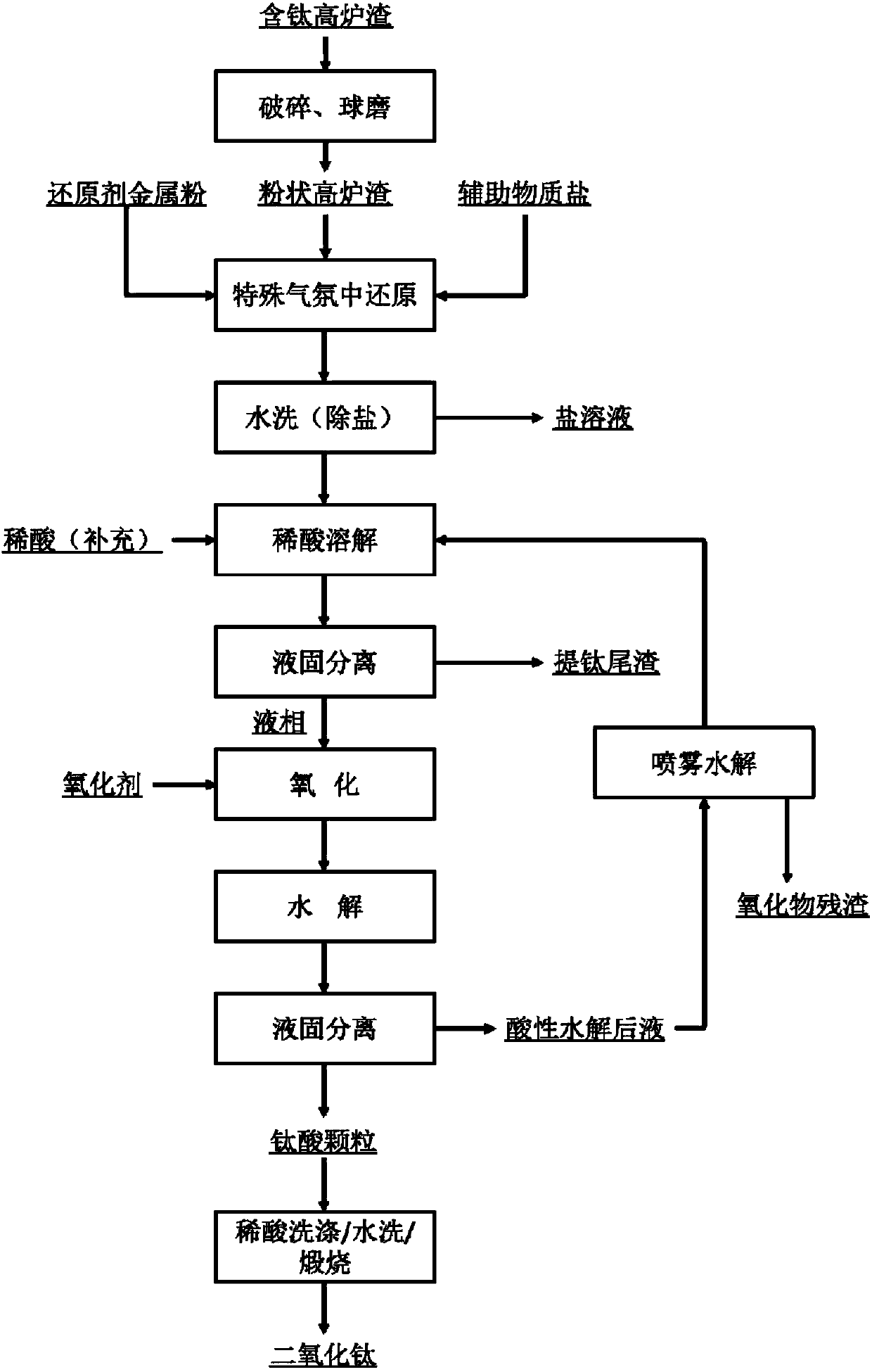

A method for efficient extraction of valuable component titanium from titanium-containing blast furnace slag

A blast furnace slag, high-efficiency technology, applied in the field of efficient extraction of titanium, a valuable component in titanium-containing blast furnace slag, can solve problems such as equipment corrosion, poor cement activity, and low TiO2 content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh a certain mass of blast furnace slag, metal aluminum powder and auxiliary substance NaCl-KCl salt after ball milling, wherein the mass ratio of blast furnace slag to aluminum powder is 14:1, and the mass ratio of blast furnace slag to auxiliary substance salt is 1:1. The molar ratio of NaCl to KCl in the material salt is 1:1; after the raw materials are mixed evenly, pour the mixed material into the molybdenum crucible, and then place the molybdenum crucible containing the material in the high temperature zone of the tubular atmosphere furnace; before heating up, first Use nitrogen to exhaust the air in the furnace tube, then switch the air flow to argon, and raise the temperature to 800°C in an argon atmosphere for 8 hours; after the program ends and the furnace body drops to 50°C, take out the materials; The NaCl-KCl salt in the reduced material was washed away, and then H + Concentration of 1mol / L hydrochloric acid pickling washing material, the volume mass rat...

Embodiment 2

[0033] Weigh a certain mass of milled blast furnace slag, metal aluminum powder and auxiliary substance AlCl 3 -KCl salt, wherein the mass ratio of blast furnace slag to aluminum powder is 9:1, the mass ratio of blast furnace slag to auxiliary substance salt is 1:0.3, and the auxiliary substance salt is AlCl 3 The molar ratio with KCl is 1:1; after the raw materials are mixed evenly, pour the mixed materials into the alumina crucible, and then place the alumina crucible containing the materials in the high temperature zone of the tubular atmosphere furnace; before heating up, first use argon exhaust the air in the furnace tube, and then raise the temperature to 500°C for 3 hours in an argon atmosphere; after the program ends and the furnace body drops to 50°C, take out the material; first use water to reduce the AlCl in the material 3 -KCl salt washed away, then H + The hydrochloric acid pickling washing material with a concentration of 5mol / L, the volume-mass ratio of dilute...

Embodiment 3

[0035] Weigh a certain mass of blast furnace slag, metal magnesium powder and auxiliary substance MgCl after ball milling 2Salt, wherein the mass ratio of blast furnace slag to magnesium powder is 3.5:1, blast furnace slag and MgCl 2 The mass ratio of salt is 1:0.5; after the raw materials are mixed evenly, pour the mixed materials into a stainless steel crucible, and then place the stainless steel crucible containing the materials in the high temperature zone of the tubular atmosphere furnace; Exhaust the air in the tube, then switch to hydrogen, and heat up to 900°C in the hydrogen atmosphere for 0.5h; after the program ends and the furnace body drops to 50°C, switch to argon to exhaust the hydrogen in the furnace tube, and then Take out the material; use H + Concentration is 8mol / L hydrochloric acid acid leaching reducing material, the volume mass ratio of dilute hydrochloric acid and reducing material during acid leaching is 8:1 (mL / g), acid leaching temperature is 100 ℃,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com