Graphene aluminum alloy and preparation method thereof

A technology of graphene and aluminum alloy, which is applied in the field of graphene aluminum alloy and its preparation, can solve the problems of uneven product particles and easy agglomeration of graphene, and achieve the effect of uniform particles, good performance and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

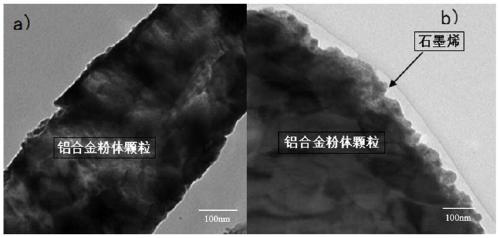

[0022] The invention provides a method for preparing a graphene aluminum alloy, including coating, drying and sintering. The coating includes: placing aluminum alloy powder particles in a vibrating fluidized bed, starting stirring, and making the aluminum alloy The powder particles are in an irregular motion state, and the graphene solution is added to the aluminum alloy powder particles in an irregular motion state by using an automatic rotating spray gun at a constant speed, and the temperature in the vibrating fluidized bed is 70-120°C , the vibrating fluidized bed is connected with a ventilation device. Aluminum matrix composites have good mechanical properties and high temperature properties. Currently, their reinforcements are mainly divided into two types: particles and fibers. Adding graphene as a reinforcement to aluminum alloys is an important breakthrough in improving the performance of aluminum matrix composites. However, the existing graphene-reinforced aluminum ...

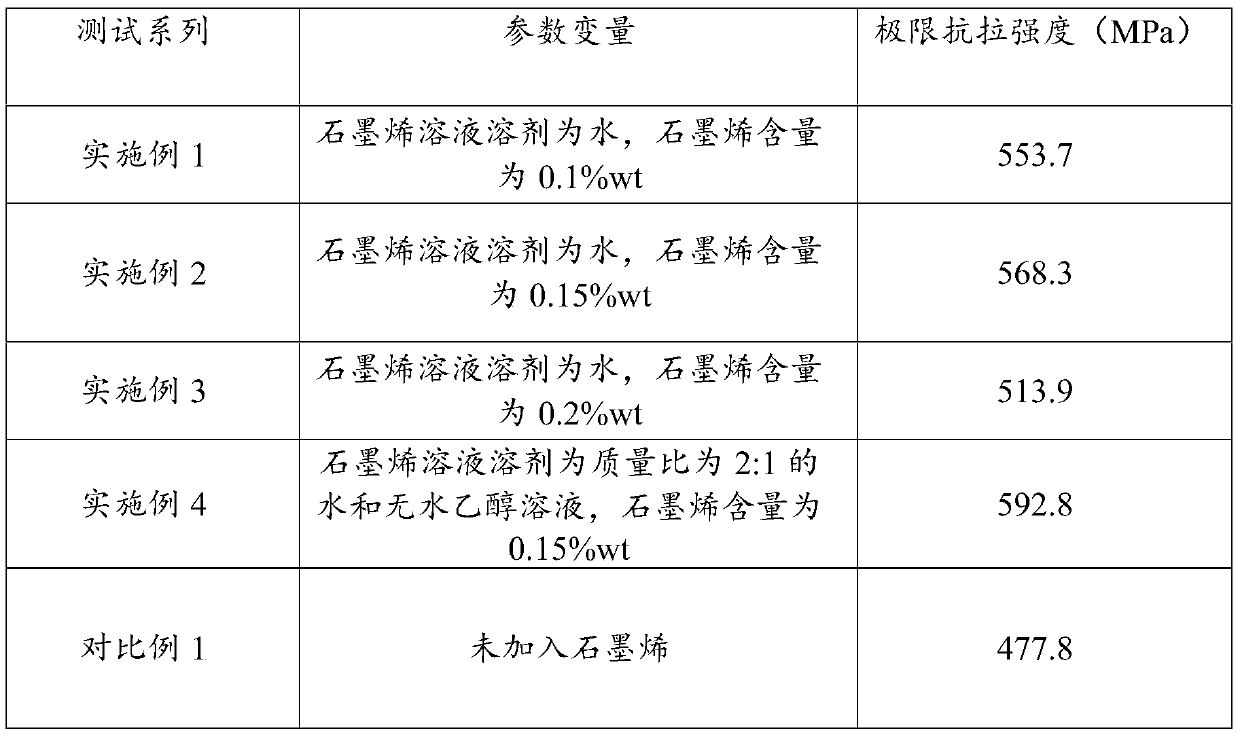

Embodiment 1

[0034] (1) Take 1000g of aluminum alloy powder particles, place them in a vibrating fluidized bed, start stirring, so that the powder is in an irregular state of motion;

[0035] (2) Get a certain amount of 0.1%wt content of graphene solution (solvent is water) and place it in the automatic rotary spray gun, turn on the rotary automatic rotary spray gun, control the flow rate to be 10ml / min, and add it to the material in step 1 at a constant speed;

[0036] (3) During the vibration process, the temperature of the fluidized bed is maintained at 110°C, so that the solvent in the graphene entering the fluidized bed can be kept in an evaporating state, and the external ventilation device is opened to continuously extract the steam;

[0037] (4) After steps 1-3 continue for 30 minutes, stop adding graphene, increase ventilation, and gradually reduce vibration frequency until the powder is dry;

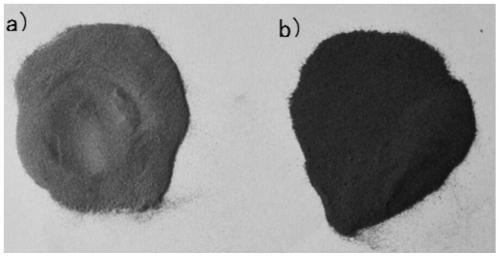

[0038] (5) Macroscopic analysis, the aluminum alloy powder after coating is obviously d...

Embodiment 2

[0041] The preparation method of the graphene aluminum alloy is the same as that of Example 1, except that the graphene content in the graphene solution is 0.15%wt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com