Double hot corner protection structure and low-temperature storage tank

A hot corner protection, low temperature storage tank technology, applied in fixed capacity gas storage tanks, outer walls of container structures, gas/liquid distribution and storage, etc. Problems such as low temperature damage of the bearing platform, to achieve the effect of less damage, reduced usage, excellent safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

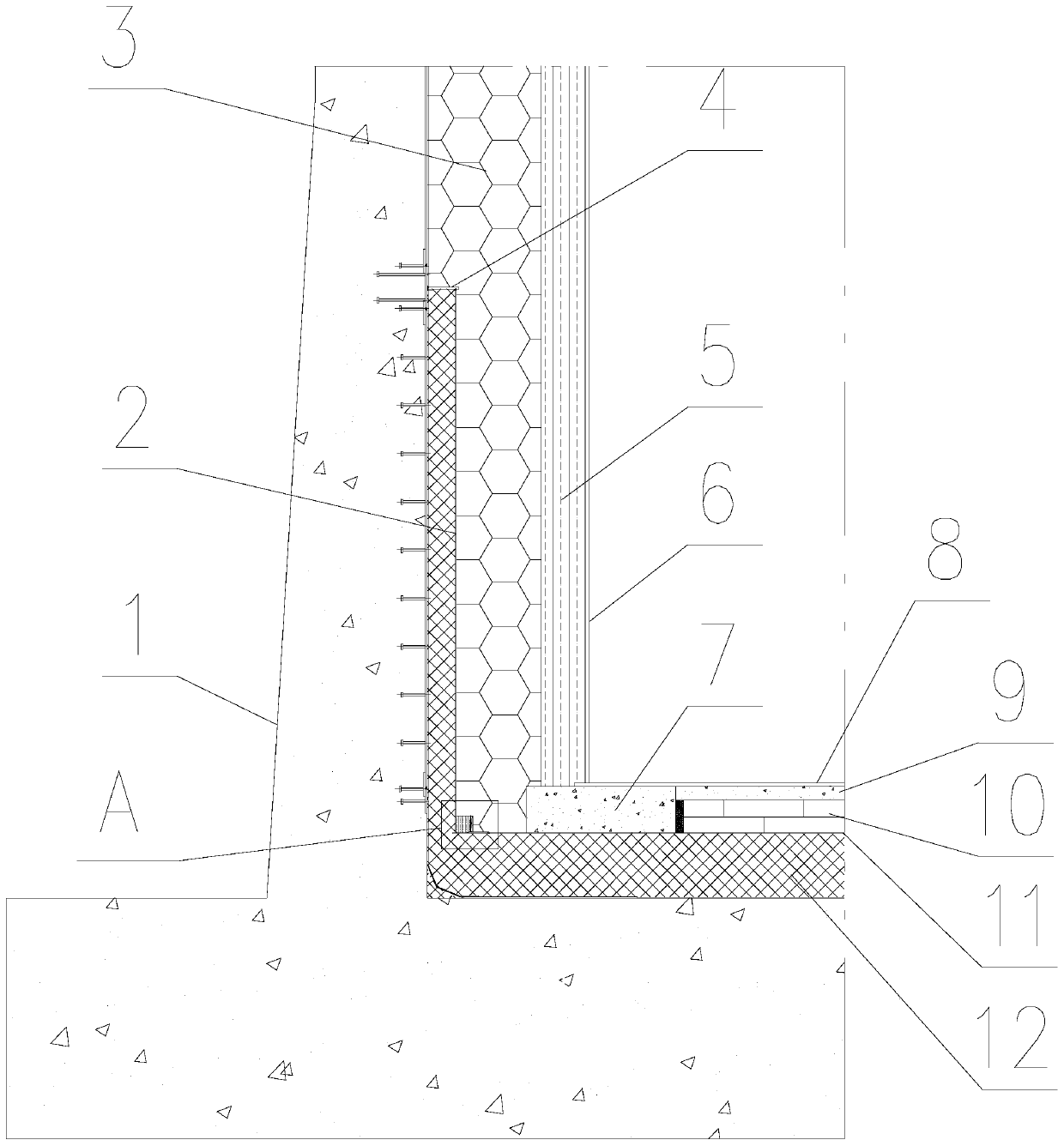

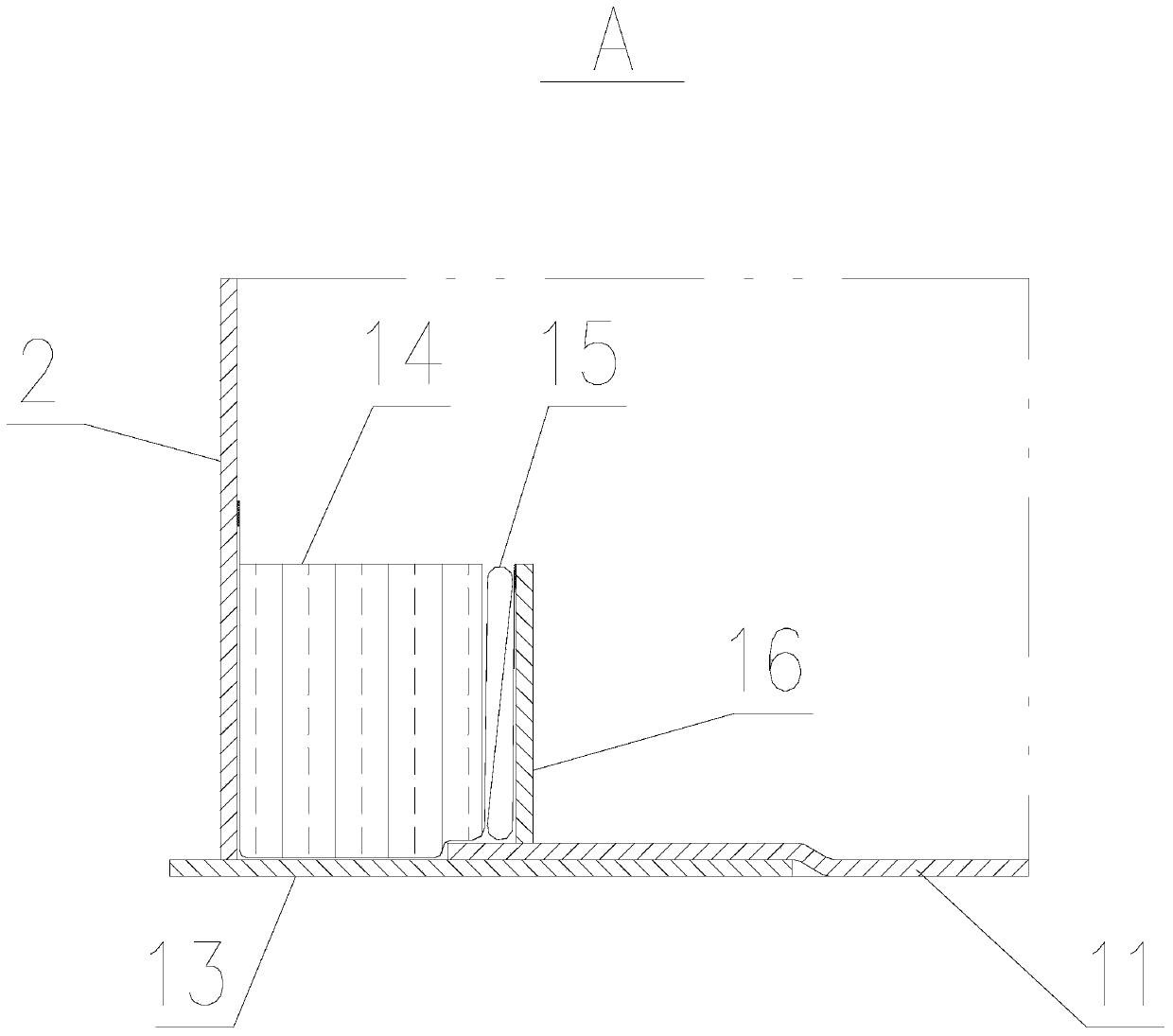

[0023] A dual thermal corner protection structure such as Figure 1 ~ Figure 2 As shown, it is arranged between the inner and outer tanks 1 of the cryogenic storage tank, including the upper hot corner structure and the lower hot corner structure 12;

[0024] The upper hot corner structure includes the hot corner protection wall plate 2 designed around the tank body, the lower edge plate 13, the upper sliding bottom plate 11, the edge baffle 16 and the flexible sealing layer 15; the lower edge plate 13 is tiled to protect the hot corner The wall plate 2 is erected at the end of the lower edge plate 13 close to the outer tank 1, and the thermal angle protection wall plate 2 and the lower edge plate 13 are preferably connected at 90° by welding or other fixing methods; the upper sliding bottom plate 11 is erected on the edge of the lower layer It can slide freely on the board 13. Specifically, the part of the upper sliding bottom plate 11 built on the lower edge plate 13 and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com