An industrial robot driver board detection card

A technology of industrial robots and board detection cards, which is applied in the direction of circuit breaker testing, single semiconductor device testing, instruments, etc., can solve the problems of high maintenance and repair costs of industrial robots, and achieve the effect of facilitating fault traceability and fault repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

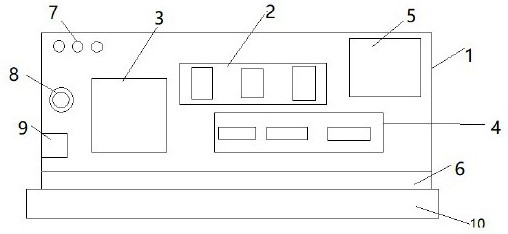

[0085] as attached figure 1 The shown industrial robot drive board detection card, an industrial robot drive board detection card, is characterized in that it includes a detection card 1, a single-chip microcomputer 3, a multi-channel analog switch 2, a gold finger and a test signal buffer 4; wherein,

[0086] The single-chip microcomputer 3 , the multi-channel analog switch 2 and the test signal buffer 4 are inserted into the chip holder preconfigured on the detection card 1 ; the multi-channel analog switch 2 and the test signal buffer 4 are electrically connected to the single-chip microcomputer 3 . connection; the multi-channel analog switch 2 and the test signal buffer 4 are electrically connected;

[0087] The detection card 1 is inserted into the preset card slot of the tested drive board 10 through the golden finger 6; wherein,

[0088] When the multi-channel analog switch 2 is turned on, the single chip 3 sends a PWM motor drive signal to the tested drive board 10, a...

Embodiment 2

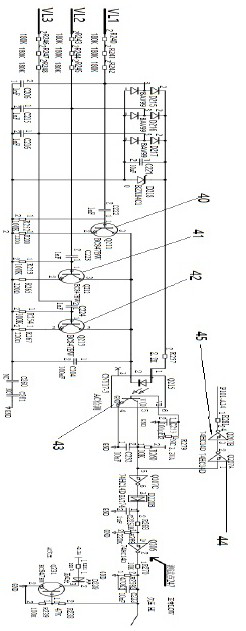

[0097] As an embodiment of the present invention: the multi-channel analog switch 2 is composed of a plurality of analog switches; the plurality of analog switches respectively control the plurality of axis joint motors connected to the detected drive board 10, and drive the motor. The analog signal of the shaft joint motor is converted into a digital signal and transmitted to the detection card 1; in the present invention, the multi-channel analog switch 2 corresponds to a plurality of shaft joint motors, and different analog switch signals control different motors.

[0098] There are multiple test signal buffers 4 , the multiple test signal buffers 4 are respectively connected with multiple analog switches, and the test signal buffers correspond to the analog switches in the multi-channel analog switches 2 .

[0099] The multi-channel analog switch 2 of the present invention is constituted by a plurality of analog switch chips, the analog chip switch is connected with the tes...

Embodiment 3

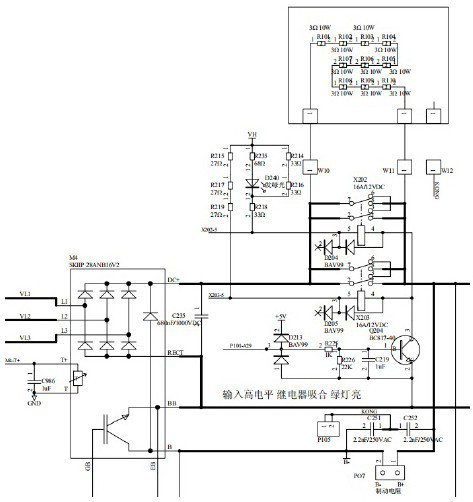

[0103] As an embodiment of the present invention: the faults include phase faults, main circuit relay faults and IGBT module faults; wherein,

[0104] The phase faults include phase loss faults and undervoltage faults;

[0105] The main circuit relay failure is the main circuit relay disconnection failure; when the main circuit relay is disconnected, the detected drive board 10 does not start.

[0106] The IGBT module fault is an IGBT module overtemperature fault.

[0107] The main fault points of the drive board detected by the present invention are the phase of the input power supply, the disconnection of the main circuit relay, and the temperature and current of the IGBT. Therefore, the present invention comprehensively detects the tested drive board from three types of faults: phase fault, main circuit relay fault and IGBT module fault.

[0108] In one embodiment, the rectifier circuit is used for external three-phase power supply; wherein, the tested drive board 10 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com