Composite electrode structure and light emitting device

A light-emitting device and composite electrode technology, which is applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of affecting the luminous efficiency of light-emitting devices and aggravating the decline of devices, so as to solve the problems of accelerating device decline, promoting electron-hole balance, The effect of avoiding recession

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

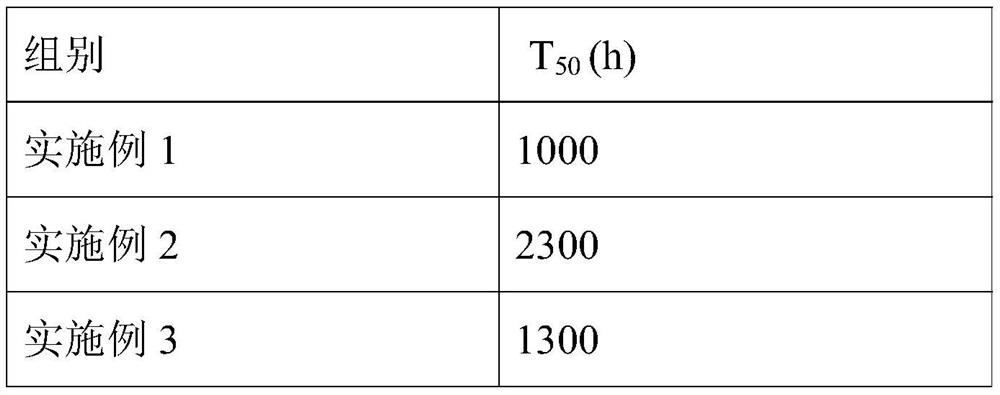

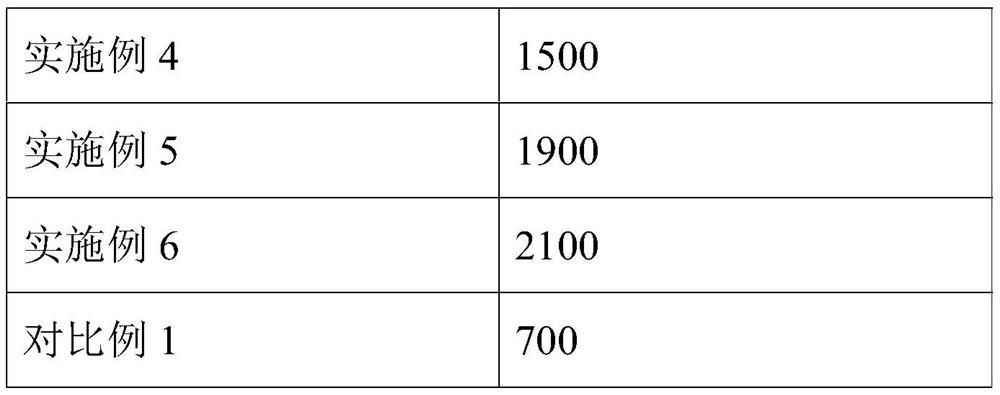

Embodiment 1

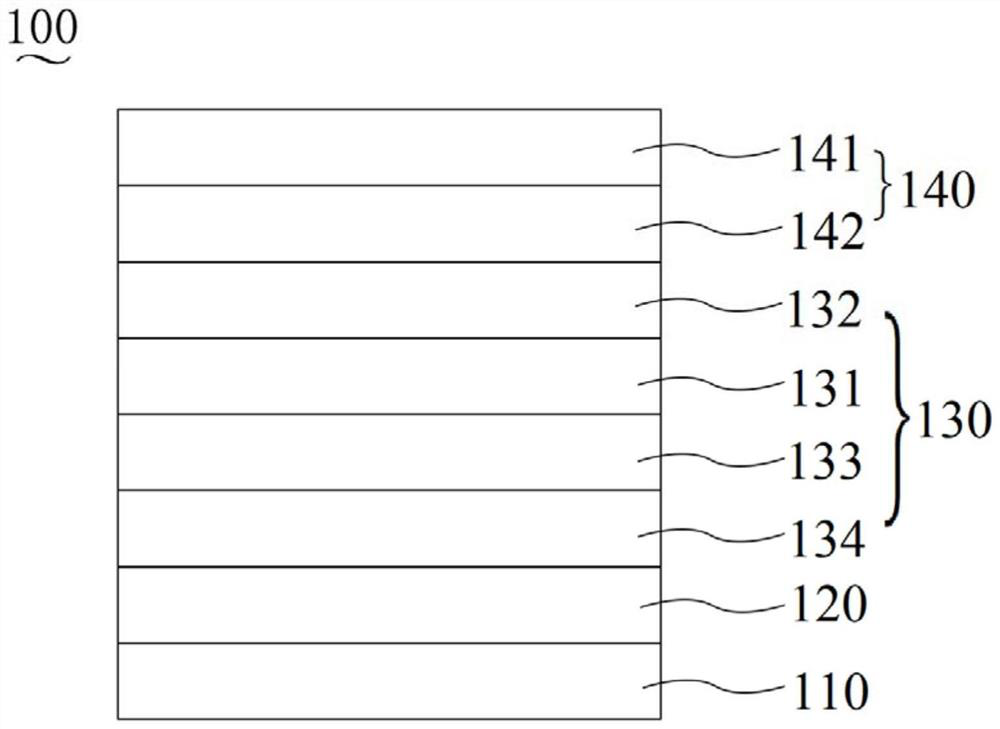

[0068] (1) Using transparent conductive film ITO as the anode, the thickness is 50nm;

[0069] (2) Depositing PEDOT by solution method on the anode:PSS is used as a hole injection layer with a thickness of 30nm;

[0070] (3) Utilizing solution method to deposit TFI on the hole injection layer as the hole transport layer, the thickness is 30nm;

[0071] (4) Depositing CdSe / ZnS as a quantum dot luminescent layer by a solution method on the hole transport layer, with a thickness of 25nm;

[0072] (5) Utilizing solution method to deposit ZnO on the quantum dot luminescent layer as the electron transport layer, the thickness is 40nm;

[0073] (6) Evaporating Cu on the electron transport layer is an electrode protection layer with a thickness of 5nm;

[0074] (7) Evaporating Al on the electrode protection layer as the Al metal electrode layer, with a thickness of 100nm;

[0075] (8) Place the above-mentioned QLED on a baking tray, and bake at 120° C. for 30 minutes.

Embodiment 2

[0077] (1) Using transparent conductive film ITO as the anode, the thickness is 50nm;

[0078] (2) Depositing PEDOT by solution method on the anode:PSS is used as a hole injection layer with a thickness of 30nm;

[0079] (3) Utilizing solution method to deposit TFI on the hole injection layer as the hole transport layer, the thickness is 30nm;

[0080] (4) Depositing CdSe / ZnS as a quantum dot luminescent layer by a solution method on the hole transport layer, with a thickness of 25nm;

[0081] (5) Utilizing solution method to deposit ZnO on the quantum dot luminescent layer as the electron transport layer, the thickness is 40nm;

[0082] (6) Evaporating Zn on the electron transport layer as an electrode protection layer, with a thickness of 5nm;

[0083] (7) Evaporating Al on the electrode protection layer as the Al metal electrode layer, with a thickness of 100nm;

[0084] (8) Place the above-mentioned QLED on a baking tray, and bake at 120° C. for 30 minutes.

Embodiment 3

[0086] (1) Using transparent conductive film ITO as the anode, the thickness is 50nm;

[0087] (2) Depositing PEDOT by solution method on the anode:PSS is used as a hole injection layer with a thickness of 30nm;

[0088] (3) Utilizing solution method to deposit TFI on the hole injection layer as the hole transport layer, the thickness is 30nm;

[0089] (4) Depositing CdSe / ZnS as a quantum dot luminescent layer by a solution method on the hole transport layer, with a thickness of 25nm;

[0090] (5) Utilizing solution method to deposit ZnO on the quantum dot luminescent layer as the electron transport layer, the thickness is 40nm;

[0091] (6) Evaporating Ag on the electron transport layer as an electrode protection layer, with a thickness of 5nm;

[0092] (7) Evaporating Al on the electrode protection layer as the Al metal electrode layer, with a thickness of 100nm;

[0093] (8) Place the above-mentioned QLED on a baking tray, and bake at 120° C. for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com