Method for preparing microbial fermented wheaten food

A microbial fermentation and pasta technology, which is applied in dough processing, food science, dough preparation, etc., can solve the problems of variable yeast quality, easy adulteration, troublesome operation, etc., and achieve easy mixing and dispersing, simple and convenient operation , the effect of uniform taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

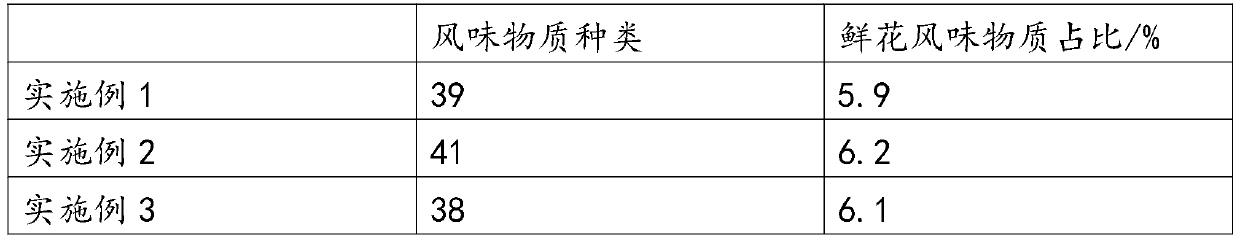

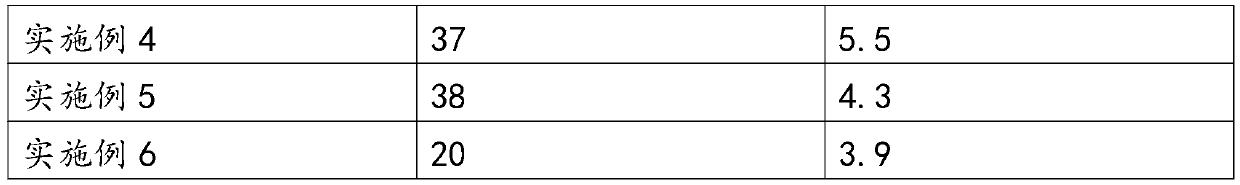

Embodiment 1

[0024] A method for preparing microbial fermented pasta, comprising the following steps:

[0025] (1) Raw material collection: Weigh fresh flowers, protein powder, probiotics, yeast, sugar cane and flour according to a certain number of parts by weight, pick the petals of the flowers, clean and dry, and squeeze the juice from the sugar cane for later use; the parts by weight of each raw material are respectively For: 30 servings of roses, 3 servings of protein powder, 1*10 probiotics 10 each, yeast 1*10 12 1, 20 parts of sugar cane, 100 parts of flour.

[0026] (2) Yeast culture: put the yeast in sugarcane juice and heat up to 40°C, and add protein powder and stir evenly. The protein powder is added every 1 hour. For 1h, the cultivation is completed to obtain the fermented liquid;

[0027] (4) Fermentation of fresh flowers: Put the drained fresh flowers in the fermentation broth and add probiotics, then heat up to 50°C for fermentation, the fermentation time is 1 hour, add ...

Embodiment 2

[0032] A method for preparing microbial fermented pasta, comprising the following steps:

[0033] (1) Raw material collection: Weigh fresh flowers, protein powder, probiotics, yeast, sugar cane and flour according to a certain number of parts by weight, pick the petals of the flowers, clean and dry, and squeeze the juice from the sugar cane for later use; the parts by weight of each raw material are respectively For: jasmine 60 parts, protein powder 8 parts, probiotics 5*10 11 each, yeast 6*10 12 , 50 parts of sugar cane, 200 parts of flour.

[0034] (2) Yeast culture: put the yeast in sugarcane juice and heat up to 45°C, and add protein powder and stir evenly. The protein powder is added every 1 hour. For 3h, the cultivation is completed to obtain the fermented liquid;

[0035] (4) Fermentation of fresh flowers: put the drained fresh flowers in the fermentation broth and add probiotics, then heat up to 60°C for fermentation. The fermentation time is 3 hours. The fresh flow...

Embodiment 3

[0040] A method for preparing microbial fermented pasta, comprising the following steps:

[0041] (1) Raw material collection: Weigh fresh flowers, protein powder, probiotics, yeast, sugar cane and flour according to a certain number of parts by weight, pick the petals of the flowers, clean and dry, and squeeze the juice from the sugar cane for later use; the parts by weight of each raw material are respectively For: Sophora japonica 45 parts, protein powder 5 parts, probiotics 2*10 11 each, yeast 4*10 12 1, 40 parts of sugar cane, 150 parts of flour.

[0042] (2) Yeast culture: put the yeast in sugarcane juice and heat up to 42°C, and add protein powder and stir evenly. The protein powder is added every 1 hour. For 2h, the cultivation is completed to obtain the fermented liquid;

[0043] (4) Fermentation of fresh flowers: Put the drained fresh flowers in the fermentation broth and add probiotics, then heat up to 55°C for fermentation, the fermentation time is 2 hours, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com