Planetary gear type mixing device

A gear type and planetary gear technology, which is applied in the field of planetary gear type mixing devices, can solve problems such as difficulty in ensuring machining accuracy and installation accuracy, weak propulsion and dispersion, and inaccurate temperature control, etc., to achieve moderate length and smooth flow , the effect of uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

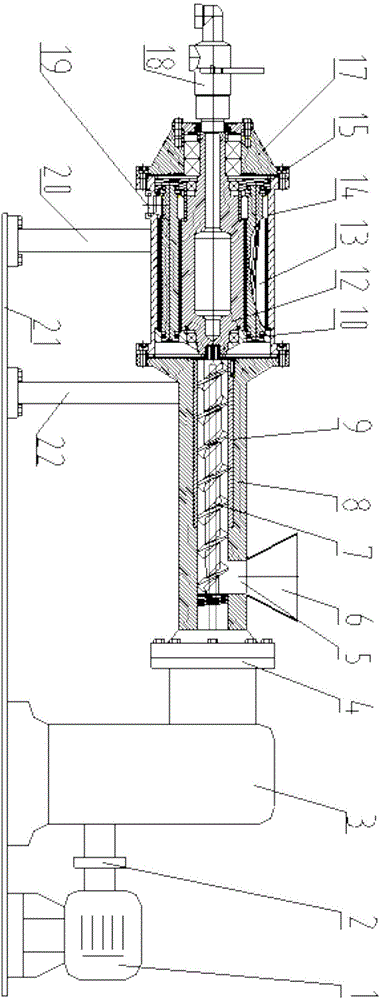

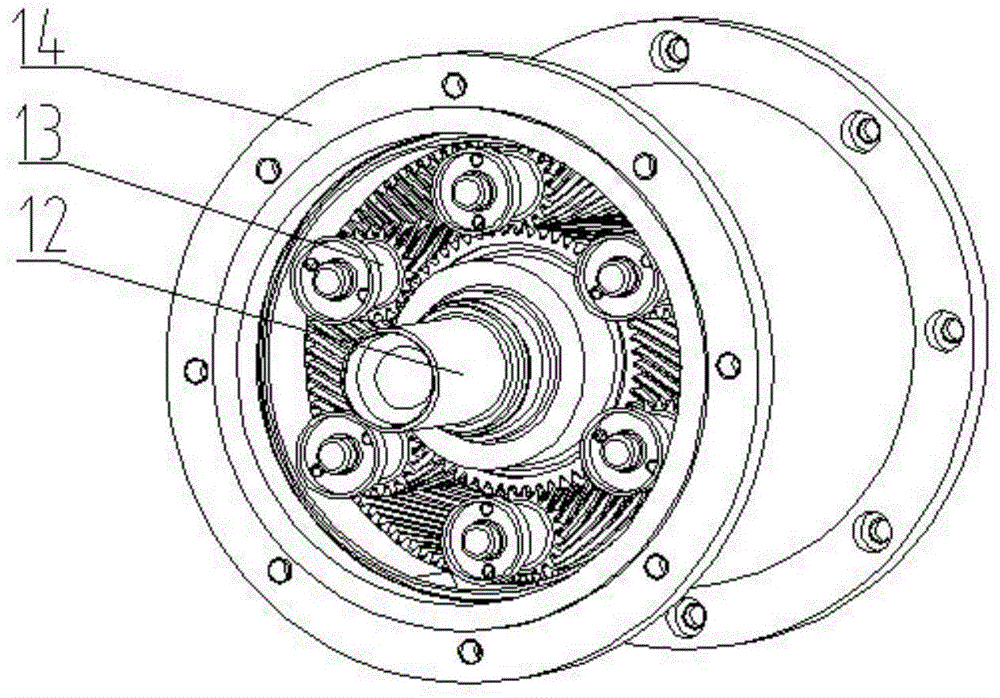

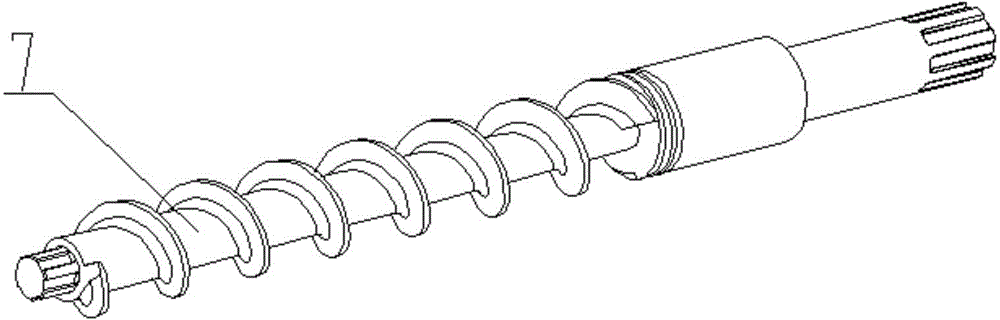

[0019] The planetary gear type mixing and extruding device involved in this embodiment includes two parts, a feeding section and a planetary section, and the specific structure (such as figure 1Shown) includes motor 1, coupling 2, reduction box 3, flange plate 4, No. 1 feed inlet 5, feeding hopper 6, feeding screw 7, barrel 8, inner bushing 9, right planet carrier 10 , No. Ⅱ feed inlet 11, sun gear screw 12, planetary gear screw 13, inner gear cylinder 14, left planet carrier 15, scraper plate 16, bearing seat 17, rotary joint 18, discharge port 19, No. 1 support frame 20. Base 21 and No. Ⅱ support frame 22. The reduction box 3 fixedly installed on the base 21 is connected to the motor 1 through the coupling 2. The cylinder 8 fixed on the base 21 by the No. 2 support frame 22 passes through the flange. The disc 4 is docked with the reduction box 3, and the barrel 8 is provided with the No. 1 feed port 5, and the No. 1 feed port 5 is fixedly welded with a funnel-shaped feeding ...

Embodiment 2

[0025] In this embodiment, the internal mixer equipped with the planetary gear type mixing device described in Example 1 and the conventional internal mixer (model X(S)M-1.7, Qingdao University of Science and Technology) in the prior art are used as comparative examples, Carry out mixing and performance testing of rubber samples to draw relevant conclusions.

example 1

[0027] In this example, it is a conventional internal mixer (model X(S)M-1.7, Qingdao University of Science and Technology) in the prior art. The internal mixer parameters are set as follows: filling factor 65±3%, rotor speed 55±3r / m, The temperature of the cooling water is 40±3℃, and the pressure of the top bolt is 0.6±0.05MPa;

[0028] Mixing process: Add 100 parts of natural rubber to the mixer for 30 seconds, then add 3.5 parts of zinc oxide, 2 parts of stearic acid, 1.5 parts of antioxidant RD, and 2 parts of plasticizer A into the mixing chamber Mix for 40 seconds, then add 30 parts of carbon black to the mixing room and mix for 40 seconds, and finally add the remaining 23.5 parts of carbon black to the mixing room for mixing, lift the top bolt once after 40 seconds, and mix again Refining for 40 seconds, unloading from the internal mixer, and then passing the roller on the open mixer to obtain the masterbatch; after parking for 3 hours, add 1.5 parts of accelerator NS a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com