Plunger type continuous extrusion granulator and activated carbon granulation process

A granulator and plunger-type technology, which is applied in the field of metallurgical sintering, can solve the problems of small-scale activated carbon, fast wear, and low equipment output, and achieve the effects of saving cost and space, increasing granulation efficiency, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

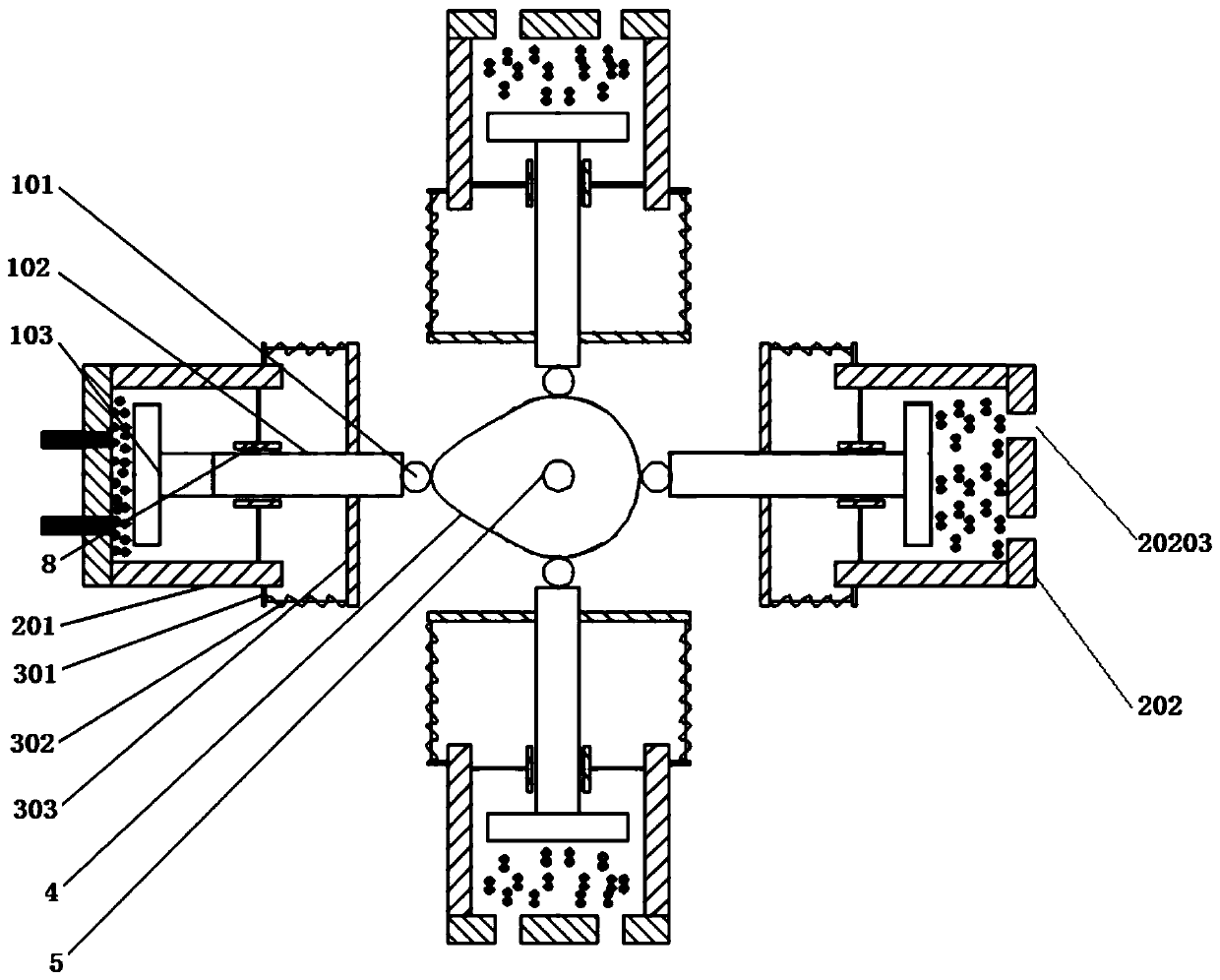

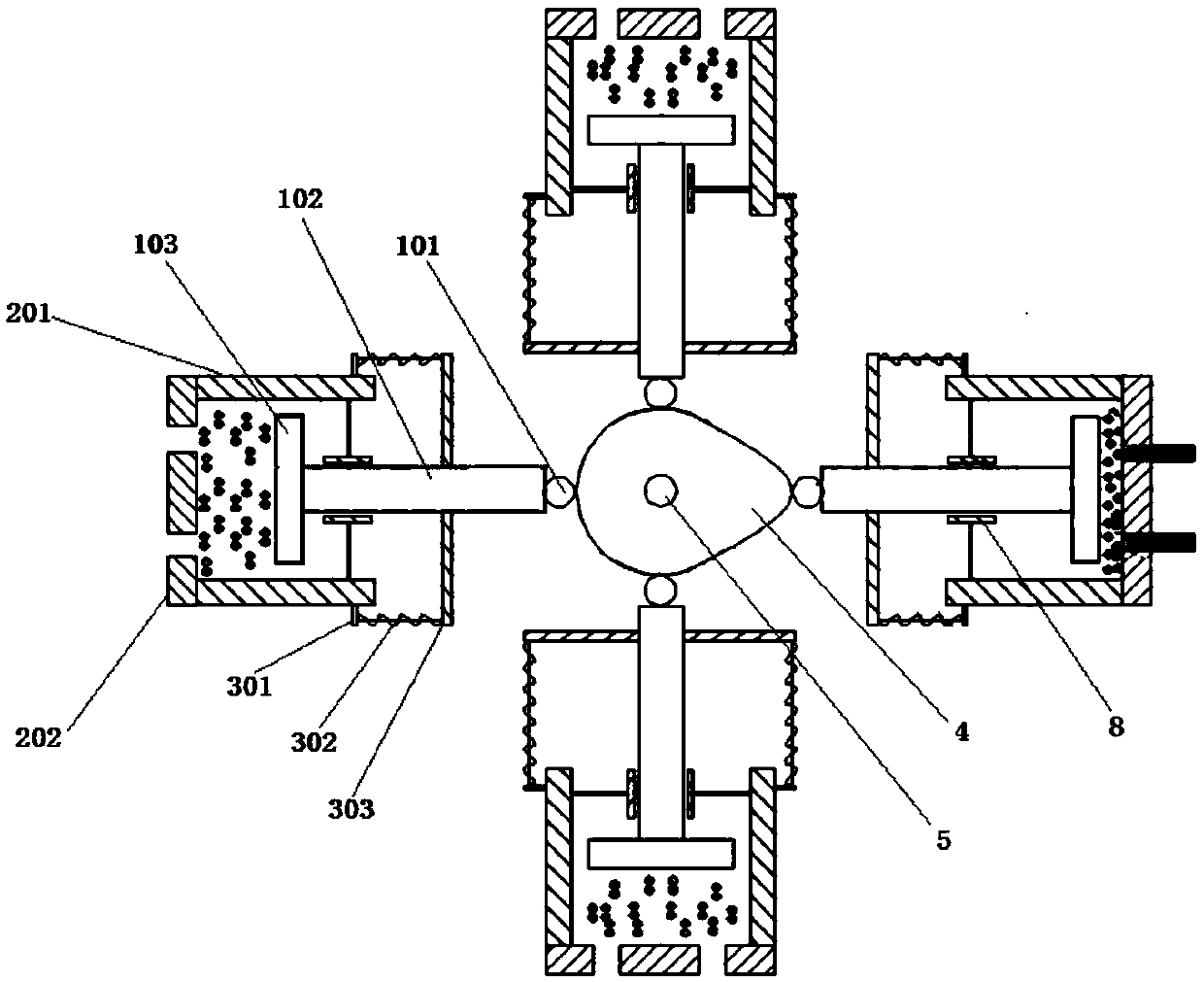

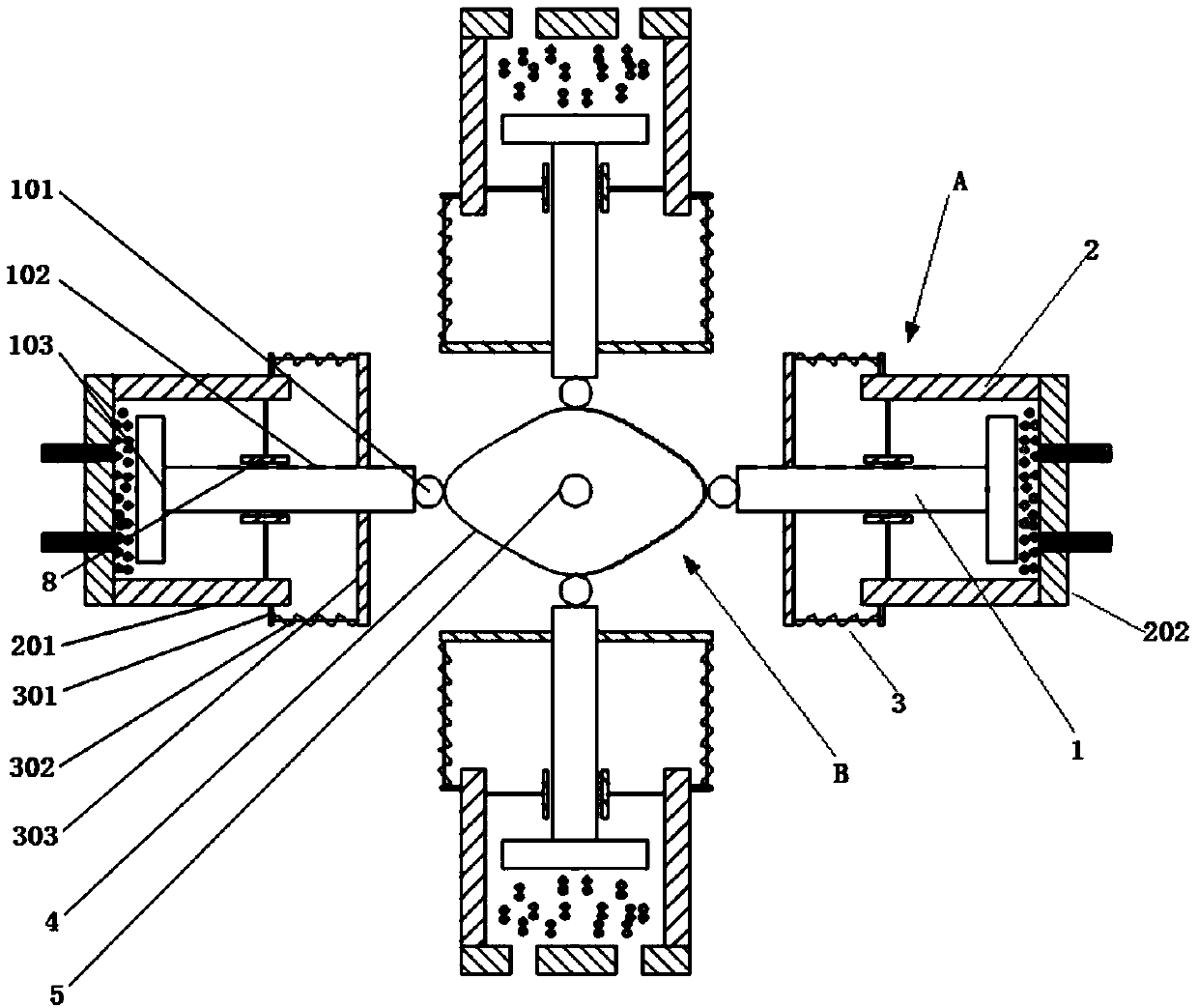

[0064] According to the first embodiment provided by the present invention, a plunger type continuous extrusion granulator is provided.

[0065] A plunger type continuous extrusion granulator, the granulator includes multiple sets of granulation units A and a set of drive units B. Each set of the granulation unit A includes a pushing device 1 , a storage tank 2 and a compression device 3 . Wherein: the pushing device 1 includes a roller 101 , a pressing rod 102 , and a pressing head 103 . One end of the pressing rod 102 is connected to the pressing head 103 , and the other end of the pressing rod 102 is provided with a roller 101 . The accumulator cylinder 2 includes a cylinder wall 201 and a die-casting mold 202 . Cylinder walls 201 are arranged on both sides and bottom of the storage cylinder 2 . The die-casting mold 202 is arranged at one end of the storage tank 2, the pressure head 103 is located in the storage tank 2, and the cylinder wall 201, the die-casting mold 202...

Embodiment 1

[0092] Such as figure 1 and 2 As shown, a plunger type continuous extrusion granulator, the granulator includes 4 sets of granulation unit A and a set of drive unit B. Each set of the granulation unit A includes a pushing device 1 , a storage tank 2 and a compression device 3 . Wherein: the pushing device 1 includes a roller 101 , a pressing rod 102 , and a pressing head 103 . One end of the pressing rod 102 is connected to the pressing head 103 , and the other end of the pressing rod 102 is provided with a roller 101 . The accumulator cylinder 2 includes a cylinder wall 201 and a die-casting mold 202 . Cylinder walls 201 are arranged on both sides and bottom of the storage cylinder 2 . The die-casting mold 202 is arranged at one end of the storage tank 2, the pressure head 103 is located in the storage tank 2, and the cylinder wall 201, the die-casting mold 202 and the pressure head 103 form a frame structure. The compression device 3 includes a spring bracket 301 , a sp...

Embodiment 2

[0094] Example 1 was repeated except that the granulator included 12 sets of granulation unit A. All the rollers 101 of the granulation unit A are in contact with the cam 4 of the drive unit B, and the cam 4 drives all the rollers 101 of the granulation unit A to rotate. 12 sets of granulation unit A are arranged in 3 layers. Each layer includes 4 sets of the granulation unit A. The 12 sets of granulation units A are evenly arranged around the driving unit B in one or more layers, and the 12 sets of granulation units A are all located under the storage unit C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com