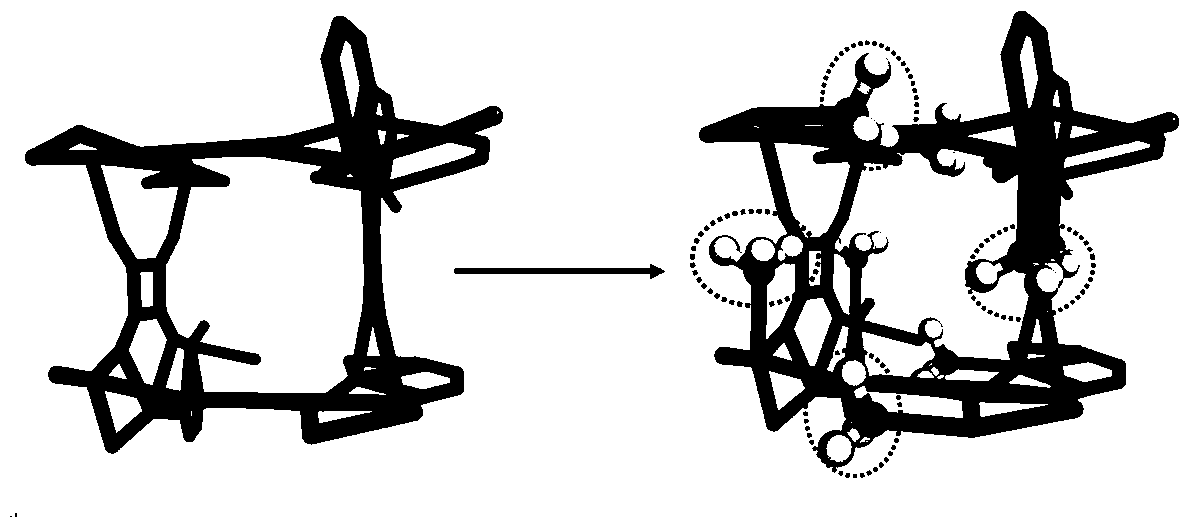

Ammonia modification method of calcium squarate and application thereof in efficient separation of ethylene and ethane

A technology of ethylene ethane and calcium squaraine, which is applied in ethylene production, adsorption purification/separation, chemical instruments and methods, etc. The effect of increasing retention time and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

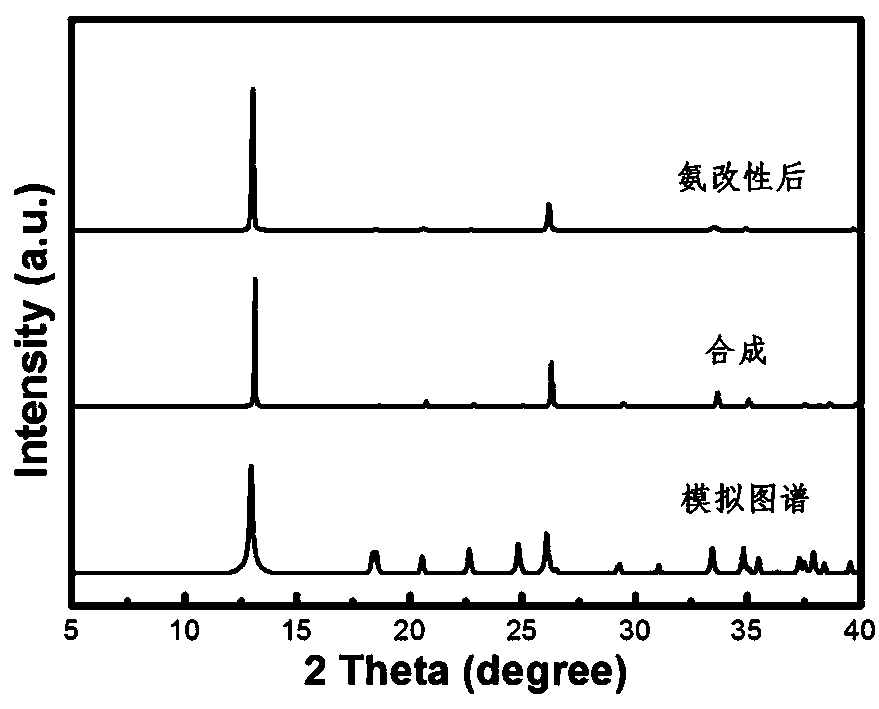

[0026] The ammonia modification method of calcium squarylate comprises the following steps:

[0027] ① Place the prepared calcium squarylate material in a high vacuum environment (1×10 -5 bar) heated at 160°C and kept for more than 3 hours. The preparation method of calcium squarylate material is well known in the art, and will not be repeated here.

[0028] ② After the activation is completed, cool the material to room temperature naturally, and then pass ammonia gas (purity above 99.99%) to 1 bar at a rate of 200 mbar / min.

[0029] ③The modification of the above steps is more critical. The material modification temperature should be between 20-30°C, and the retention time during the ammonia modification process should be more than 1 hour. The above process ensures that the ammonia adsorption of the material is saturated. In this embodiment, the mass of the calcium squarylate material remains constant when the ammonia adsorption is saturated.

[0030] ④ After the ammonia a...

Embodiment 2

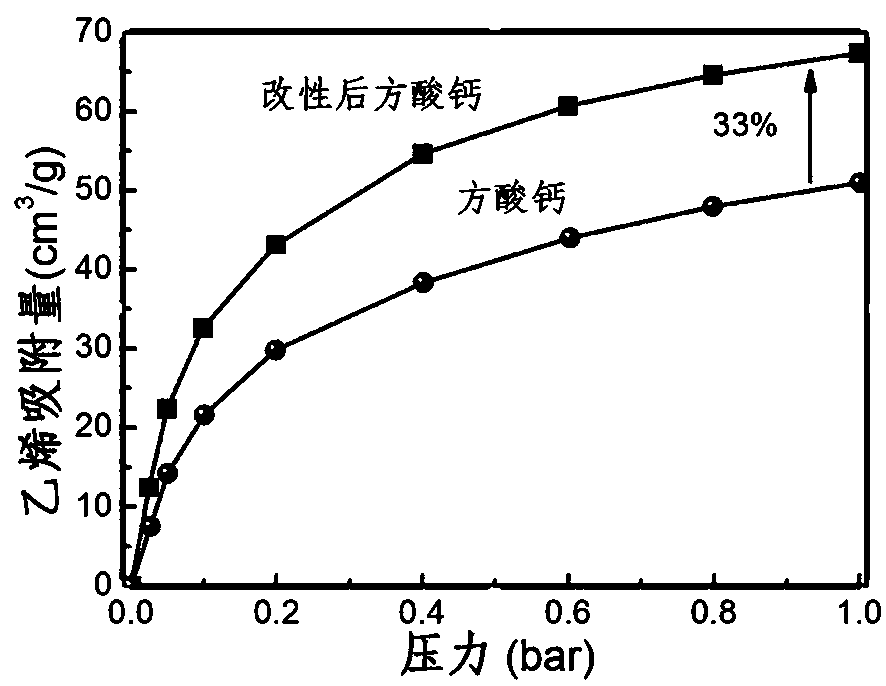

[0033] The ethylene adsorption properties of calcium squarylate materials with different ammonia modification amounts were tested.

[0034] Get ten calcium squarylate materials that the amount of ammonia modification in Example 1 is 0.05%, 0.5%, 1%, 1.6%, 3.2%, 3.7%, 4.8%, 6.6%, 8.2% and 10% at room temperature The ethylene adsorption test was carried out under the following conditions, and the final adsorption capacity was compared with that of the calcium squarylate material without ammonia modification. The results are shown in Table 1. In this example, the calcium squarylate material that has not been modified by ammonia has only completed the high-vacuum and high-temperature activation in step ① in Example 1.

[0035] Table 1 Effect of different amounts of ammonia modification on ethylene adsorption of calcium squarate materials

[0036]

[0037] Due to the dual effects of pore volume and ammonia modification position, too large ammonia modification amount or too low ...

Embodiment 3

[0039] Application testing of ethylene ethane separation using ammonia-modified calcium squarylate material.

[0040] ① Take 0.9 g of the calcium squarylate material in Example 1 with an ammonia modification amount of 1% and fill it into a separation column of Φ4×120 mm, and take 0.9 g of the calcium squarylate material without ammonia modification and fill it into a separation column of Φ4×120 mm The separation column was used as a control.

[0041] ②Purge the separation column with helium gas for 30 minutes at the set temperature of 80°C, and the flow rate of the purge is 100ml / min.

[0042] ③After purging, cool down to room temperature naturally, and use ethaneethylene (1:1 volume ratio) feed gas to penetrate the adsorption column at room temperature (25°C), and set the flow rate to 1.5mL / min.

[0043] ④ Take samples from the gas outlet every 2-3 minutes and inject them into the chromatographic analyzer to analyze the effluent components.

[0044] ⑤ Carry out content anal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com