Coal mill explosion-proof detection system and method for coal-fired boiler of generator set

A technology for coal-fired boilers and generator sets, applied in the field of coal mills, can solve problems such as poor results, and achieve the effect of avoiding explosions and ensuring safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

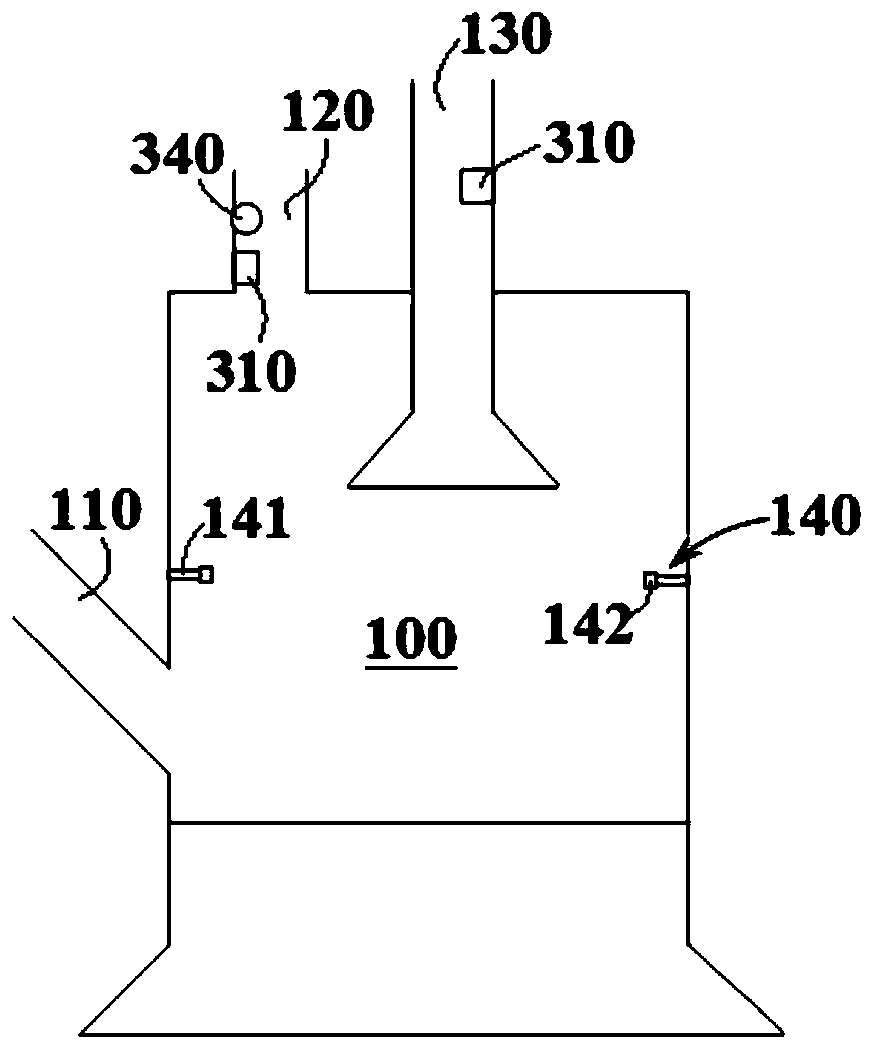

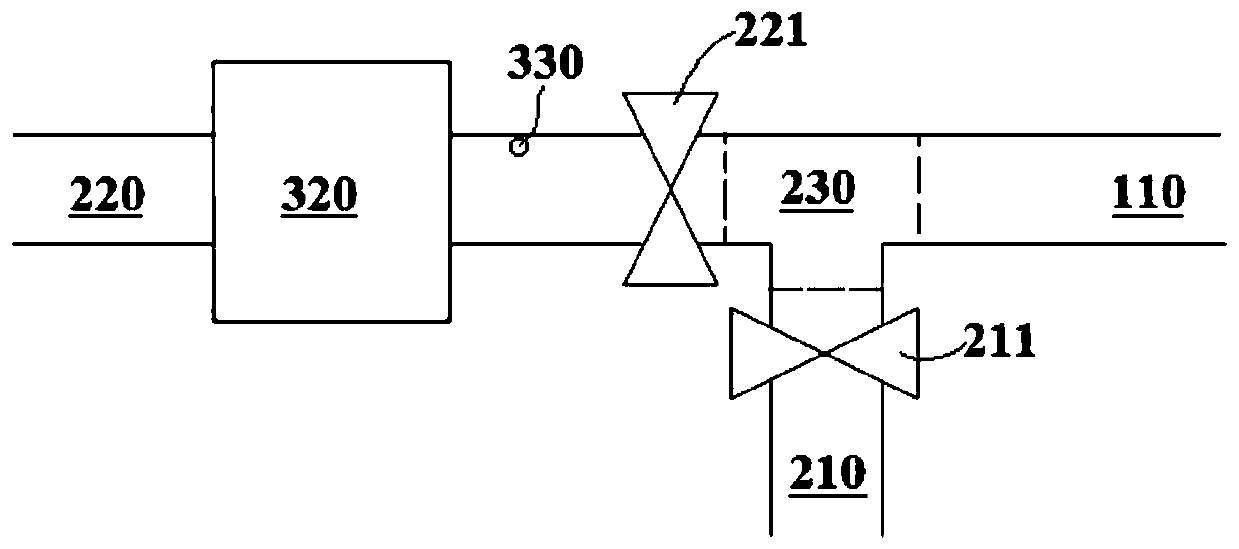

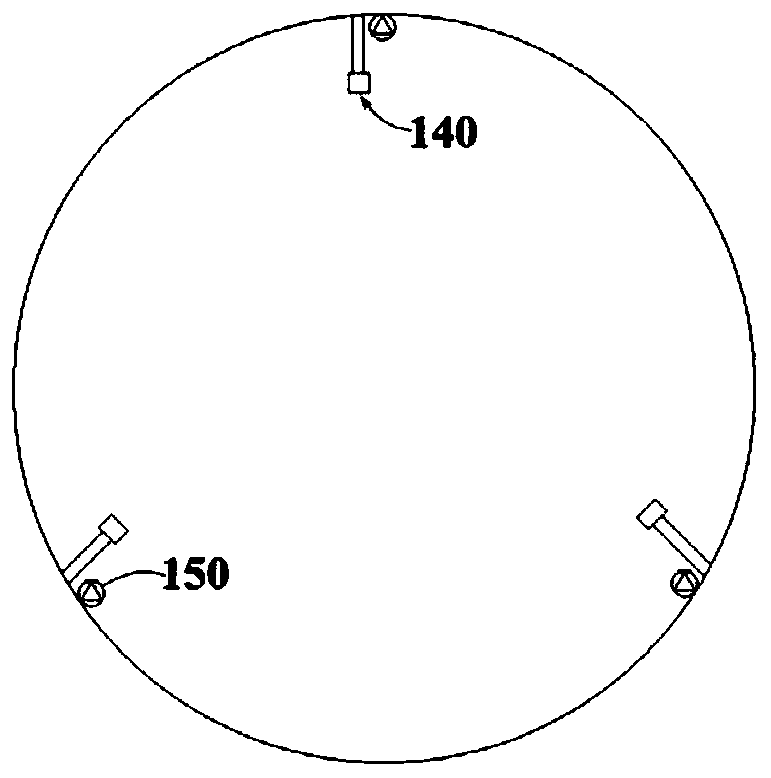

[0035] combine figure 1 As shown, a coal mill explosion-proof detection system for a coal-fired boiler of a generating set according to the present invention includes a coal mill body 100, an inert gas pipe 210 and a control center. The inert gas pipe 210 is connected to the coal mill body 100. The inert The gas pipe 210 is used to transmit the inert gas to the coal mill body 100 , so as to control the pulverized coal concentration and oxygen volume content in the coal mill body 100 . It is worth noting that the coal mill body 100 of the present invention is a coal mill for a coal-fired boiler of a power unit; further, the coal mill body 100 of the present invention is provided with an inlet hot air pipe 110, a pulverized coal outlet pipe 120 and a raw coal The inlet pipe 130 and the inert gas pipe 210 are connected to the inlet hot air pipe 110. In this embodiment, the inlet hot air pipe 110 is arranged on the side of the coal mill body 100, and the pulverized coal outlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com