High-pressure water descaling system and descaling method

A high-pressure water descaling and descaling system technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of poor descaling effect, complex structure, difficult maintenance, etc., and achieve good descaling effect , High degree of intelligence, less equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

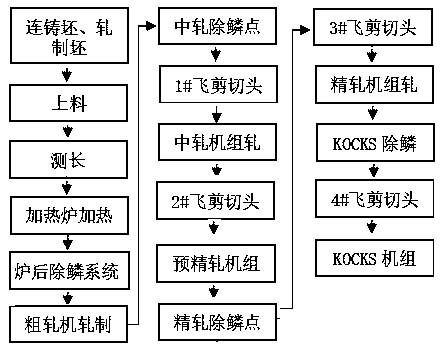

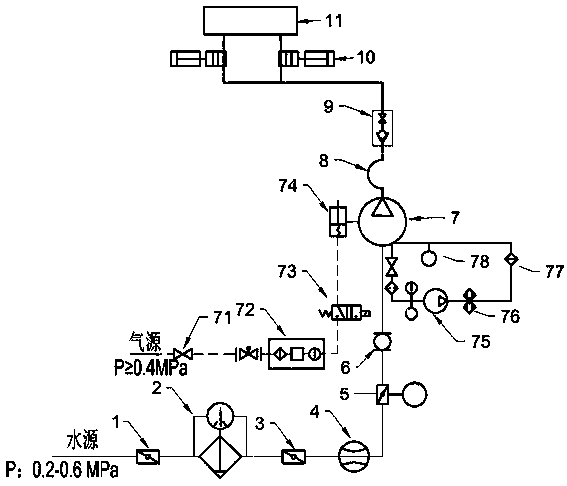

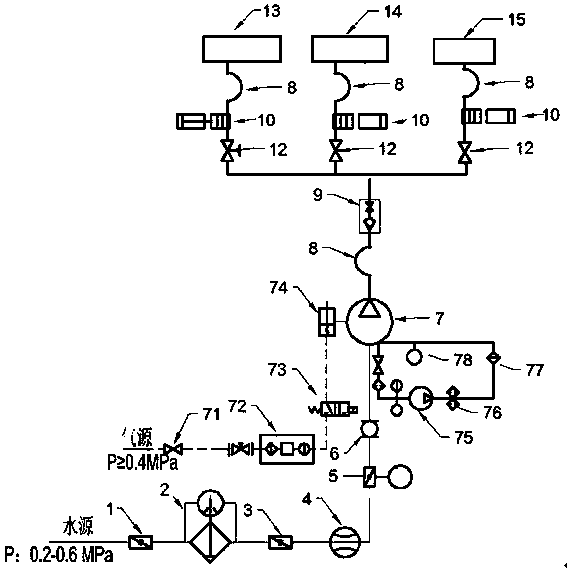

[0025] The square steel billet with a size of 280mm×280mm×6000mm is heated by the heating furnace and then passes through the high-pressure water descaling device behind the furnace to remove the oxide scale on the surface of the billet. The descaled square steel billet is sent to the first six rough rolling stands alternately arranged horizontally and vertically for non-twist and micro-tension rolling, and then sent to the input roller table of the middle rolling group through the ground. High-pressure water descaling is installed in front of the middle rolling group A set of equipment is used to remove the secondary oxide scale. After the secondary descaling of the rolled piece, the 1# flying shear is used to cut the head and the tail, and then enter the 6-stand alternately arranged middle rolling group for non-torsion and micro-tension rolling. A set of high-pressure water descaling device is installed in front of the pre-finishing rolling unit, which is used to remove the s...

Embodiment 2

[0033] The square steel billet with a size of 150mm×150mm×12000mm is heated by the heating furnace and then passes through the high-pressure water descaling device behind the furnace to remove the oxide scale on the surface of the billet. The descaled square steel billet is sent to the first six rough rolling stands alternately arranged horizontally and vertically for non-twist and micro-tension rolling, and then sent to the input roller table of the middle rolling group through the ground. High-pressure water descaling is installed in front of the middle rolling group A set of equipment is used to remove the secondary oxide scale. After the secondary descaling of the rolled piece, the 1# flying shear is used to cut the head and the tail, and then enter the 6-stand alternately arranged middle rolling group for non-torsion and micro-tension rolling. A set of high-pressure water descaling device is installed in front of the pre-finishing rolling unit, which is used to remove the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com