Forging method capable of enhancing compaction effect of 42CrMo continuous casting billet

A technology of continuous casting slabs and continuous casting round slabs, which is applied in the field of iron and steel material equipment manufacturing process control, can solve the problems of increasing forging time and forging times, increasing the risk of coarse grain of forgings, and low production efficiency, so as to achieve extended use Long life, enhanced compaction effect, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

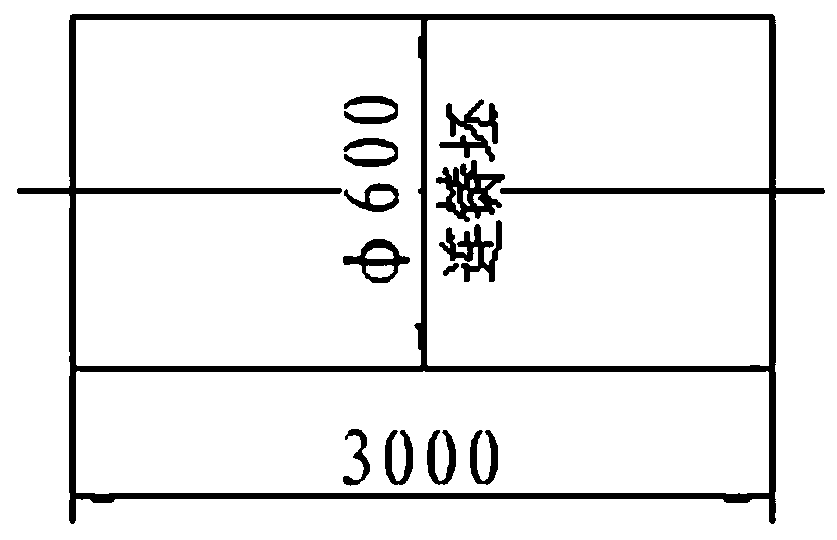

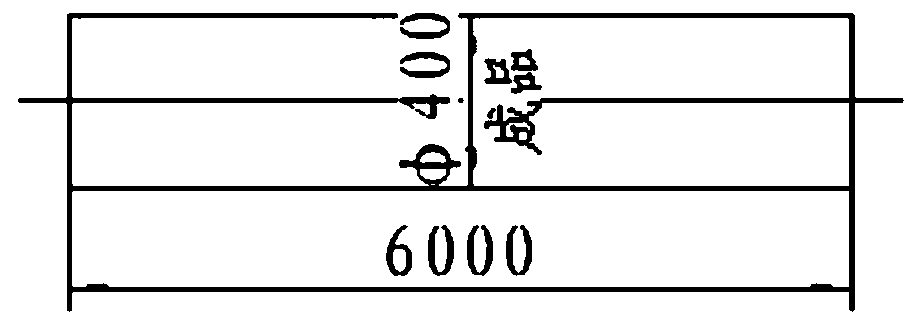

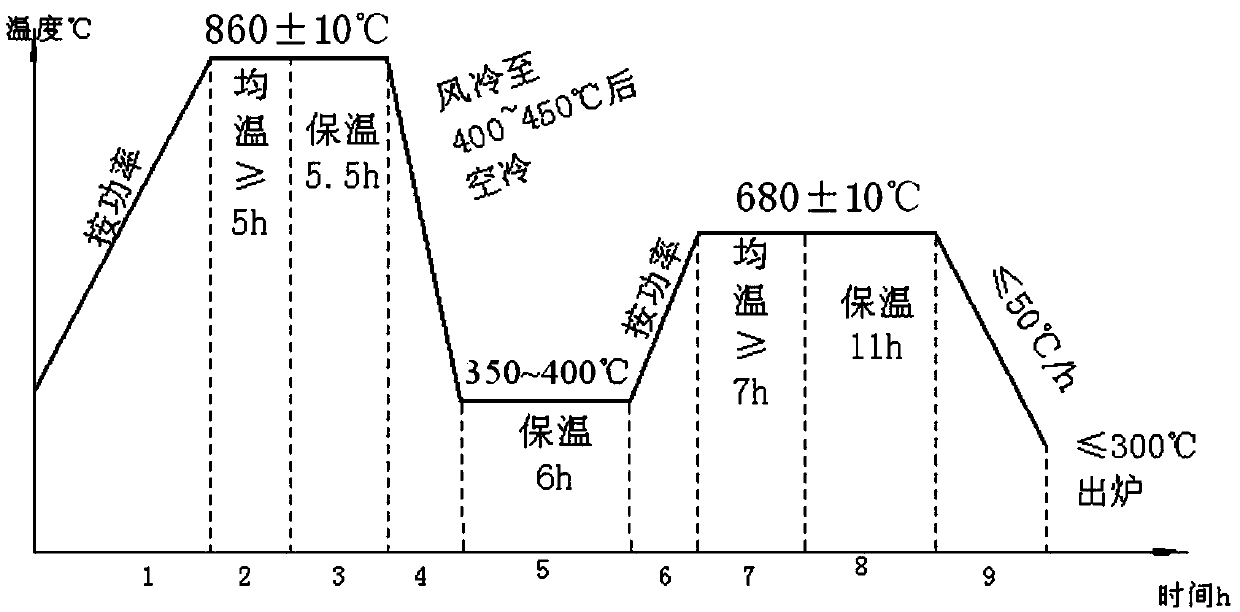

[0023] The implementation of the technical solution of the present invention mainly lies in the design of the pre-forging heating process and the control of the forging process. According to the size of the 42CrMo continuous casting slab, the pre-forging heating specification and forging deformation mode are reasonably designed; As well as the drawing speed and forging frequency during the forging of the precision forging machine to solve the internal compaction problem of the forging; after the forging is completed, carry out post-forging normalizing + tempering, straightening, physical and chemical testing, surface inspection, ultrasonic flaw detection and sawing blanking Waiting for work.

[0024] A forging method for enhancing the compaction effect of 42CrMo continuous casting slabs, the production process of which is as follows:

[0025] 42CrMo batching→electric arc furnace smelting→LF ladle smelting→VD vacuum degassing furnace→continuous casting→continuous casting slab h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com