Briquette compactor

A technology for compactors and briquettes, which is applied to presses, manufacturing tools, etc., can solve the problems that smoke and dust cannot be effectively controlled, waste coal energy, and cannot generate coke, etc., so as to facilitate smoke and dust collection, high coke generation rate, The effect of reducing a lot of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Next, the present invention will be described in detail with reference to the drawings.

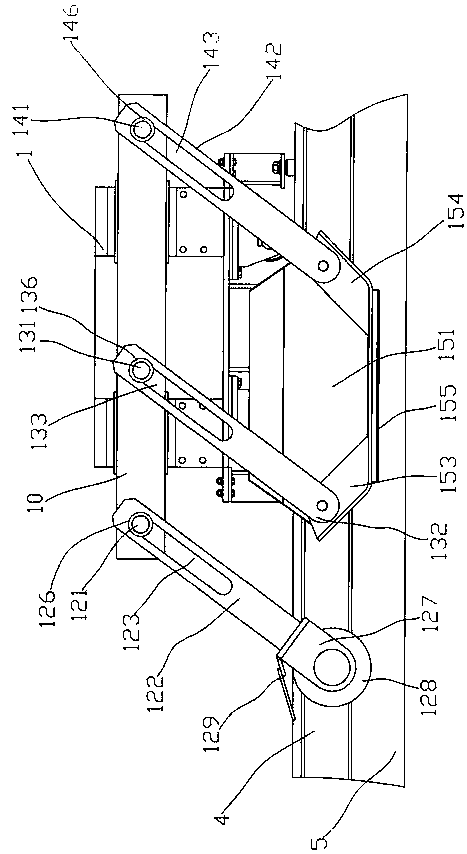

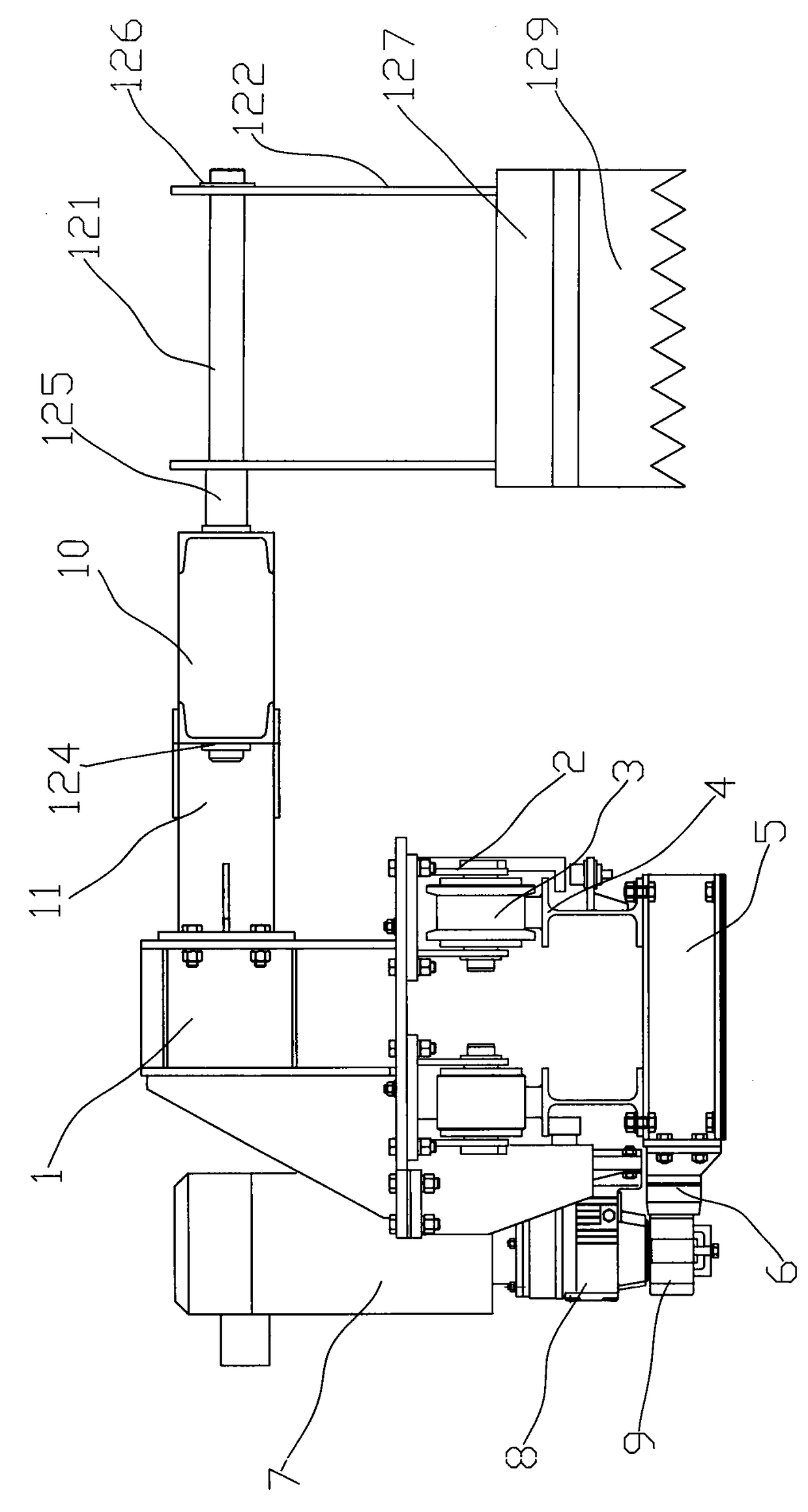

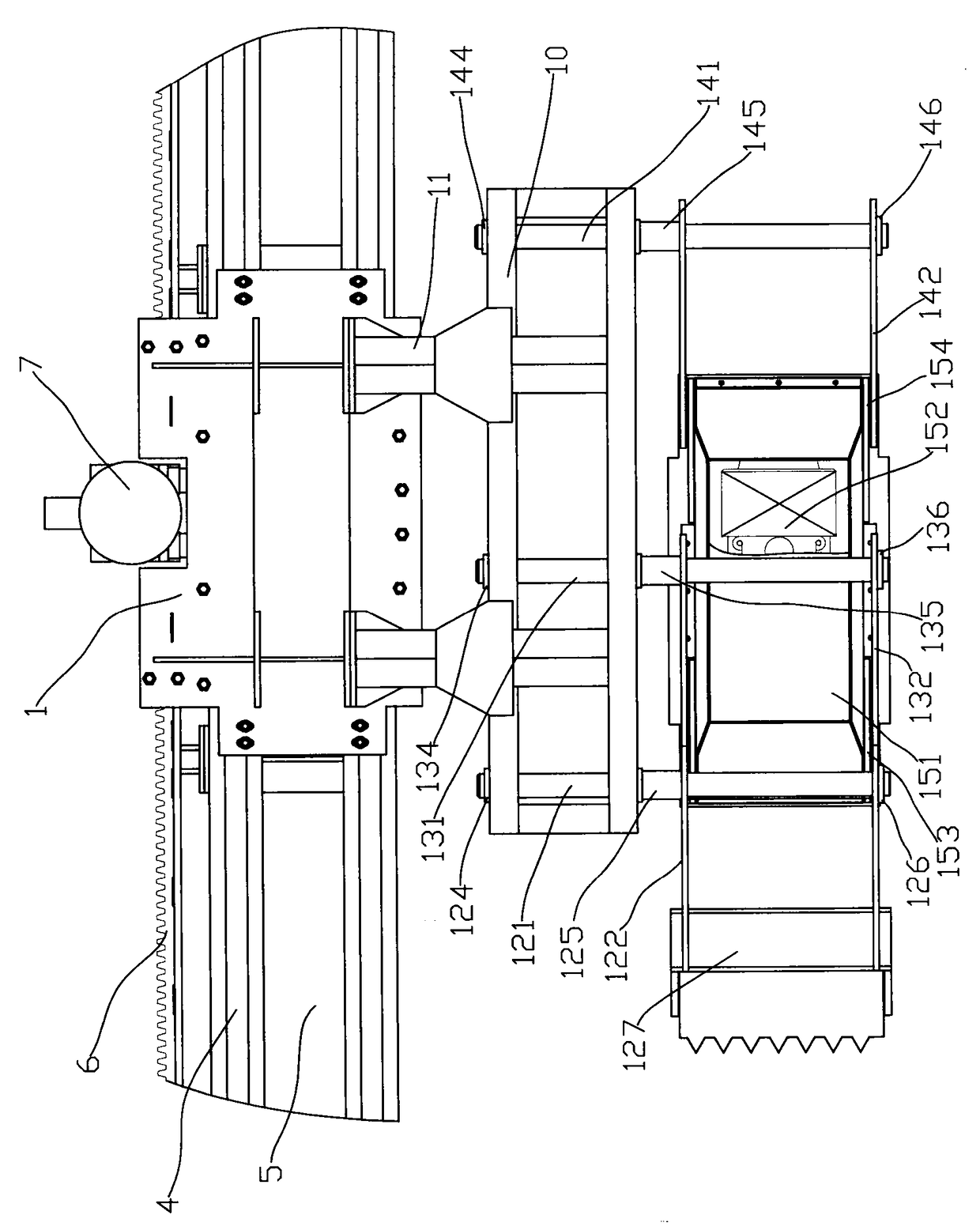

[0022] Such as figure 1 , figure 2 as well as image 3 As shown, the lower part of the base frame 1 is provided with two sets of opposite wheel frames 2, in which the rail wheels 3 are installed, and the two sets of rail wheels are respectively seated on two horizontal rails 4, and the rails are set on the horizontal rail bracket 5, a horizontal rack 6 is arranged on one side of the guide rail bracket; a motor 7 and a reducer 8 are arranged on one side of the above-mentioned base frame, and the output end of the motor is connected with the input end of the reducer. The end is provided with a gear 9 matched with the above-mentioned rack; the other side of the base frame is the side opposite to the motor is provided with a shaft frame 10, which is connected to the base frame through two connecting beams 11; A front pressing assembly and a rear pressing assembly are arranged on the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com