6R industrial robot inverse kinematics solving method

An industrial robot and inverse kinematics technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as complicated results, great influence on convergence and precision, and complicated solution process, so as to improve efficiency and attitude accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

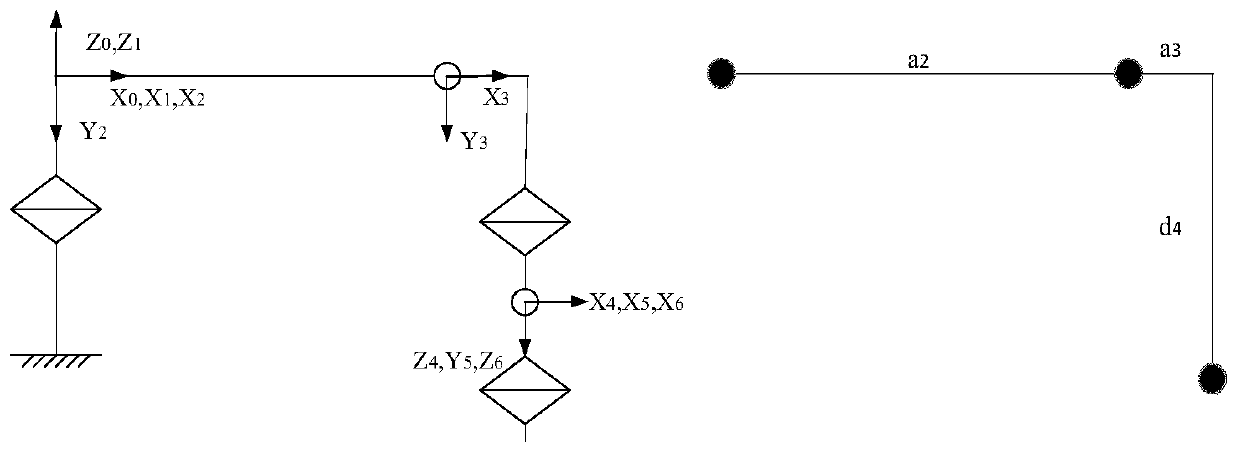

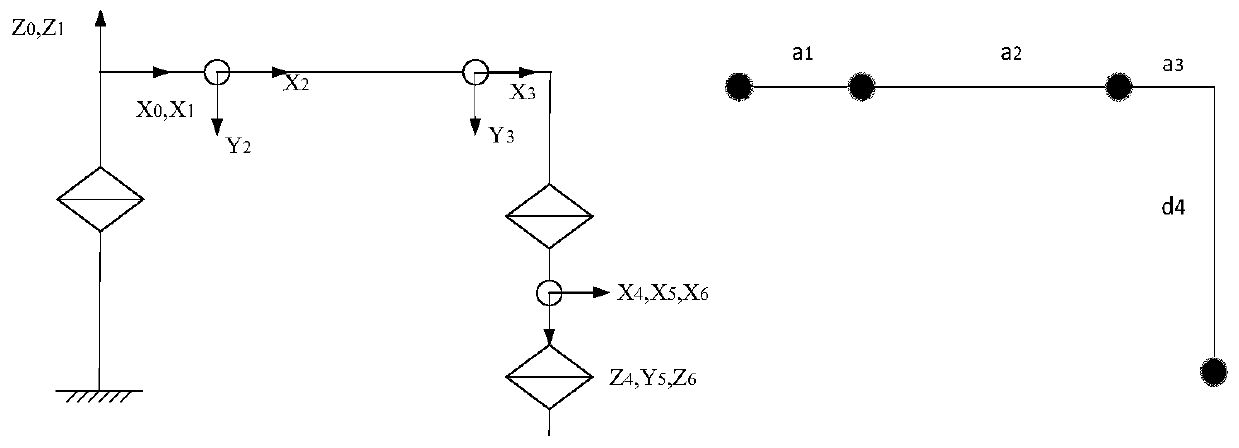

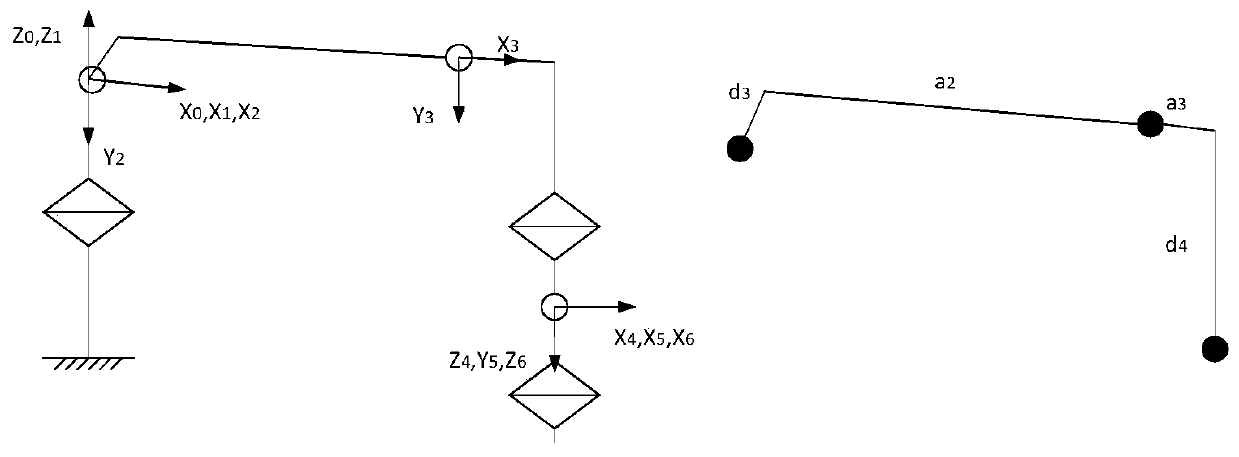

[0052] See Figure 1 to Figure 7 , a 6R industrial robot inverse kinematics solution method, the method includes the following steps:

[0053] Step 1: Establish the coordinate system, geometric simplified model and D-H table of the 6R robot;

[0054] Step 2: According to the geometrically simplified model, establish the functional relationship between the joint angle of the first joint and the spatial coordinate of the origin of the coordinate system of the end link;

[0055] Step 3: Under the condition that the joint angle of the first joint has been determined, the spatial position relationship of the second link and the third link is simplified into a triangle, and the functional relationship between the joint angle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com