Automatic taking control system and method for unmanned crown block

A technology of automatic retrieving and control methods, applied in the direction of load hanging components, transportation and packaging, etc., can solve problems such as prone to accidents and affect the normal operation of operators, and achieve the effect of non-disturbance switching and improving grabbing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the examples.

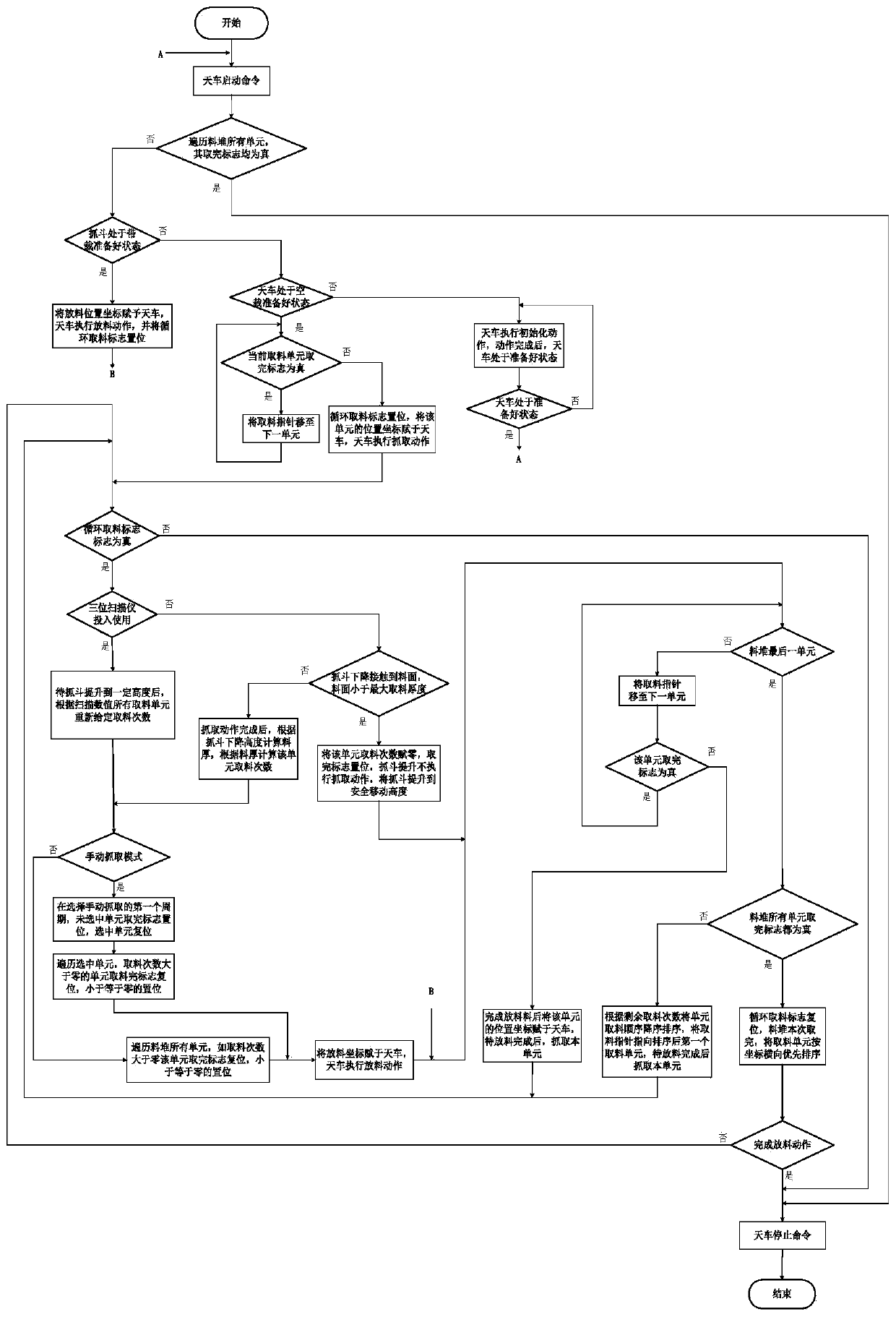

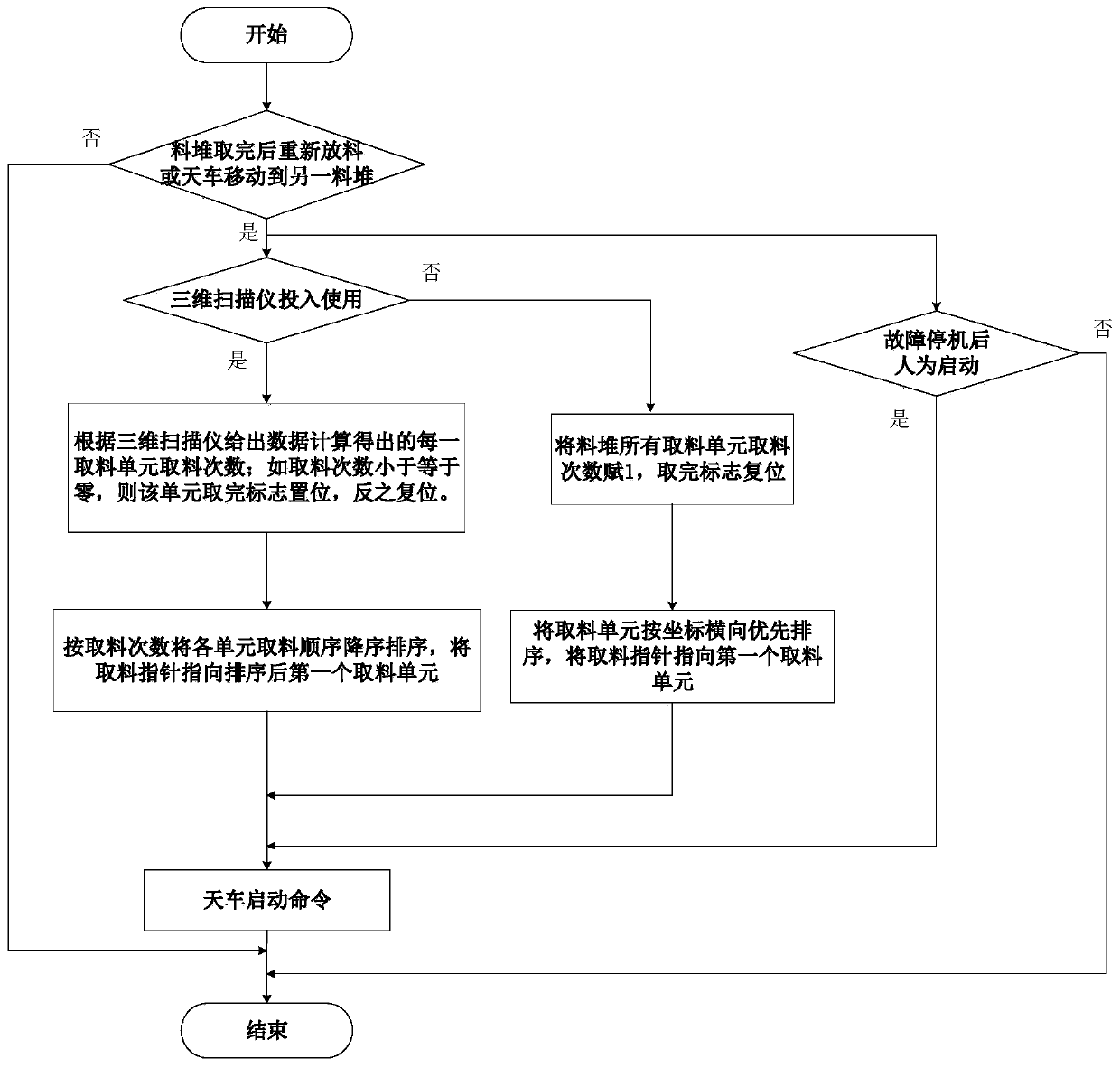

[0033] The invention discloses a control method for automatic reclaiming of unmanned cranes, see Figure 1-Figure 2 , the specific steps are:

[0034] 1.1. Divide the stockpile into N=i×j retrieving units horizontally and vertically, establish a coordinate system with the upper left corner of the stockpile as the absolute zero point, and the center coordinates of each reclaiming unit are the position coordinates of the reclaiming unit.

[0035] 1.2. Create a one-dimensional array of N elements, the element attributes include X, Y, Z, COUNT, FLAG; among them, X: unit abscissa, Y: unit ordinate, Z: unit material thickness, COUNT: unit retrieving times, FLAG: The unit has completed the flag.

[0036] 1.3. After the stockpile is reloaded or the crane is moved to another stockpile, if the 3D scanner is put into use, execute 1.4; otherwise, execute 1.5.

[0037]1.4 According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com