Water stop inspection and leakage treatment structure of plunge pool structural joint and water stop inspection and leakage treatment method

A technology for structural joints and water cushion ponds, which is applied in water conservancy projects, sea area engineering, coastline protection, etc. It can solve problems such as difficult to observe the surface, flooded corridors, and instability of the bottom of the water cushion pond, and achieve simple construction and convenient inspection , high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] According to the area of the inspection area and the amount of water seepage, choose one of the following implementation modes. When the inspection area is large or the leakage is small, you can choose implementation mode 1, otherwise choose implementation mode 2.

Embodiment approach 1

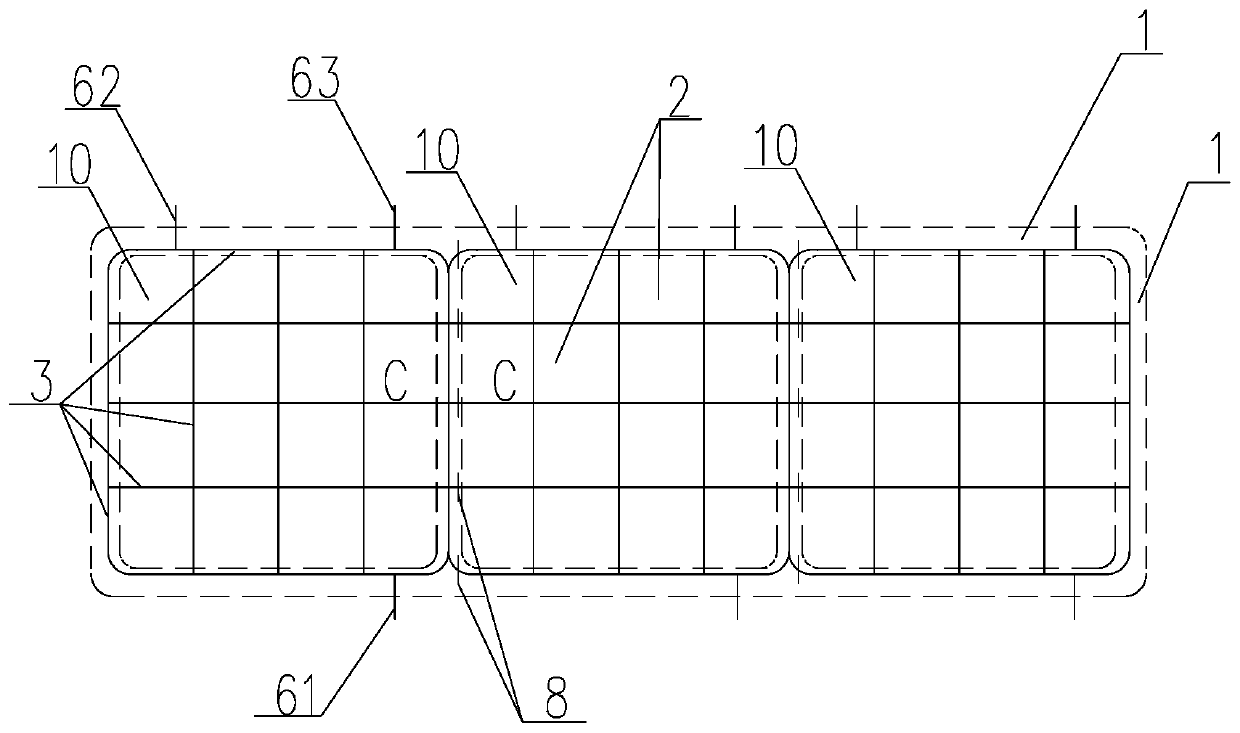

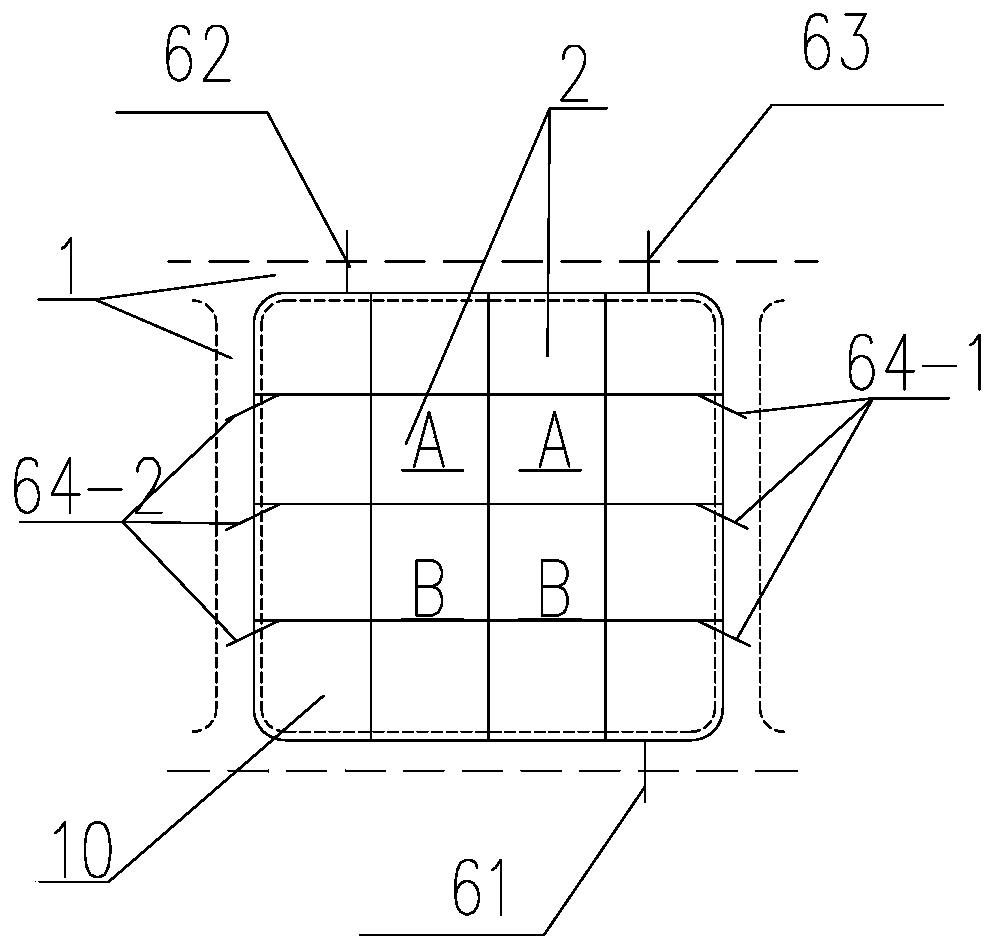

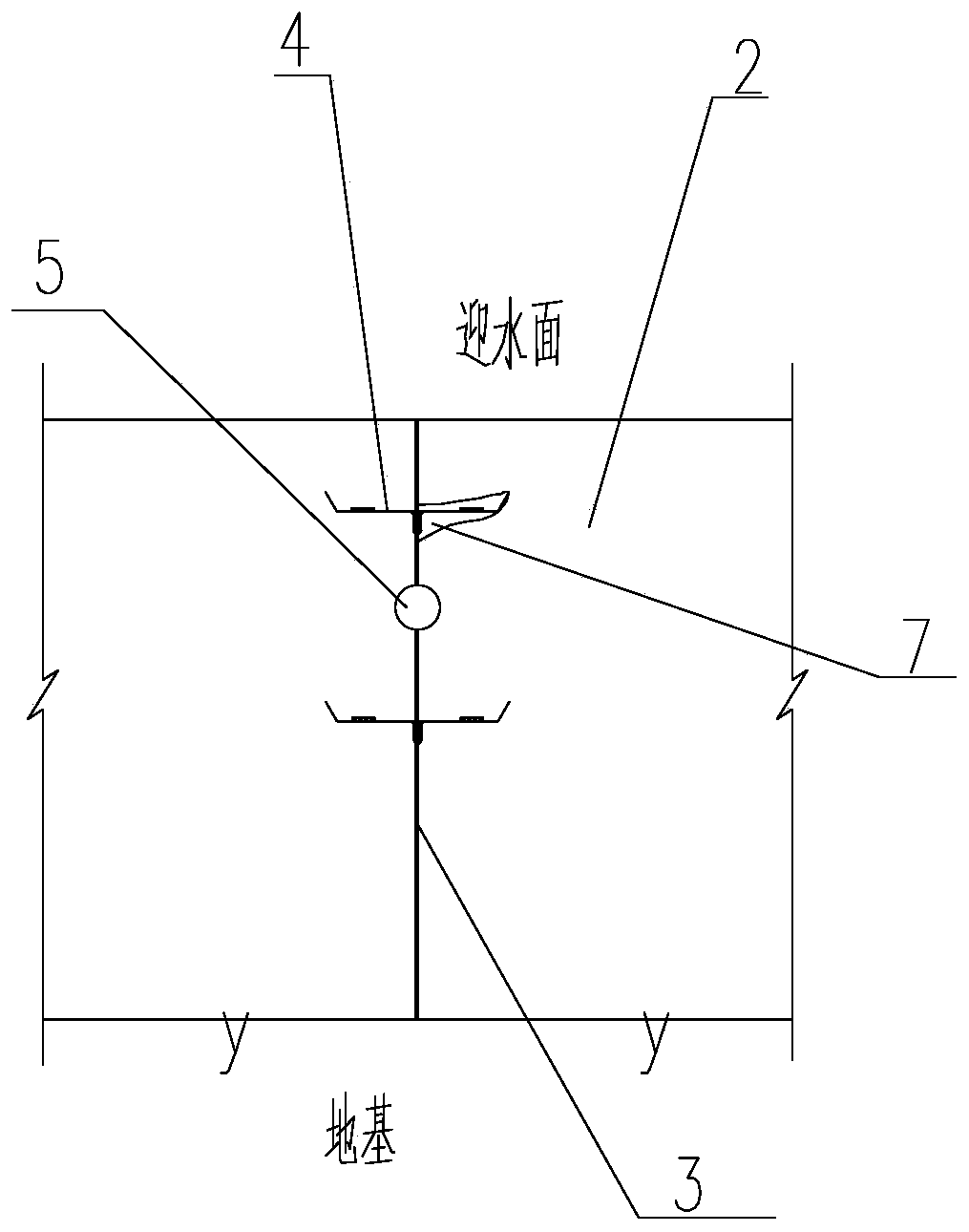

[0035] Embodiment 1, close all grouting pipes 64-1 and grouting pipes 64-2 in the inspection area, pour water-soluble polyurethane grout into the hollow groove through the pre-buried water inlet pipe 61 in the foundation corridor, and grout along the The hollow groove 5 of the structural joint flows, penetrates into the concrete gap, and fills the gap defect 7 between the concrete and the water-stop copper sheet 4 . After the outlet pipe 62 and exhaust pipe 63 in the other corridor have thick slurry, close the corresponding outlet pipe and exhaust pipe mouth, and after the slurry is discharged for 20 minutes to stabilize the pressure, close the water inlet pipe 61, and wait for the slurry to solidify for 24 hours after the end.

Embodiment approach 2

[0036] Embodiment 2: Water-soluble polyurethane grout is poured into the hollow groove through the pre-embedded steel pipe (grouting pipe 64-1) in the foundation corridor, and the grout flows along the hollow groove 5 of the structural joint under a certain grouting pressure, penetrates into the concrete gap, fills the concrete and The gap defect 7 between the water-stop copper sheets 4. After the grout outlet pipe 64-2 nozzle, water inlet pipe 61, outlet pipe 62, and exhaust pipe 63 in the other corridor are discharged from the thick slurry, the corresponding slurry outlets are closed one by one, and after the slurry is discharged and the pressure is stabilized for 20 minutes, the grouting pipe 64 is closed. -1, after the slurry solidifies for 24 hours, it ends.

[0037] The cured slurry not only fills the defect 7 between the concrete and the water-stop copper sheet 4, but also forms a water-stop strip with certain elasticity and water-swelling in the hollow groove 5, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com