Pump self sealing water device

A self-sealing and water-sealing technology, which is applied to components, pump components, mechanical equipment, etc. of pumping devices for elastic fluids, can solve the problems of increased maintenance costs and maintenance risks, failure of the machine pump to be normally backed up, and failure of the machine seal to be heated. Equalize the problem, achieve the effect of reducing maintenance costs and maintenance safety risks, avoiding damage due to uneven heating, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

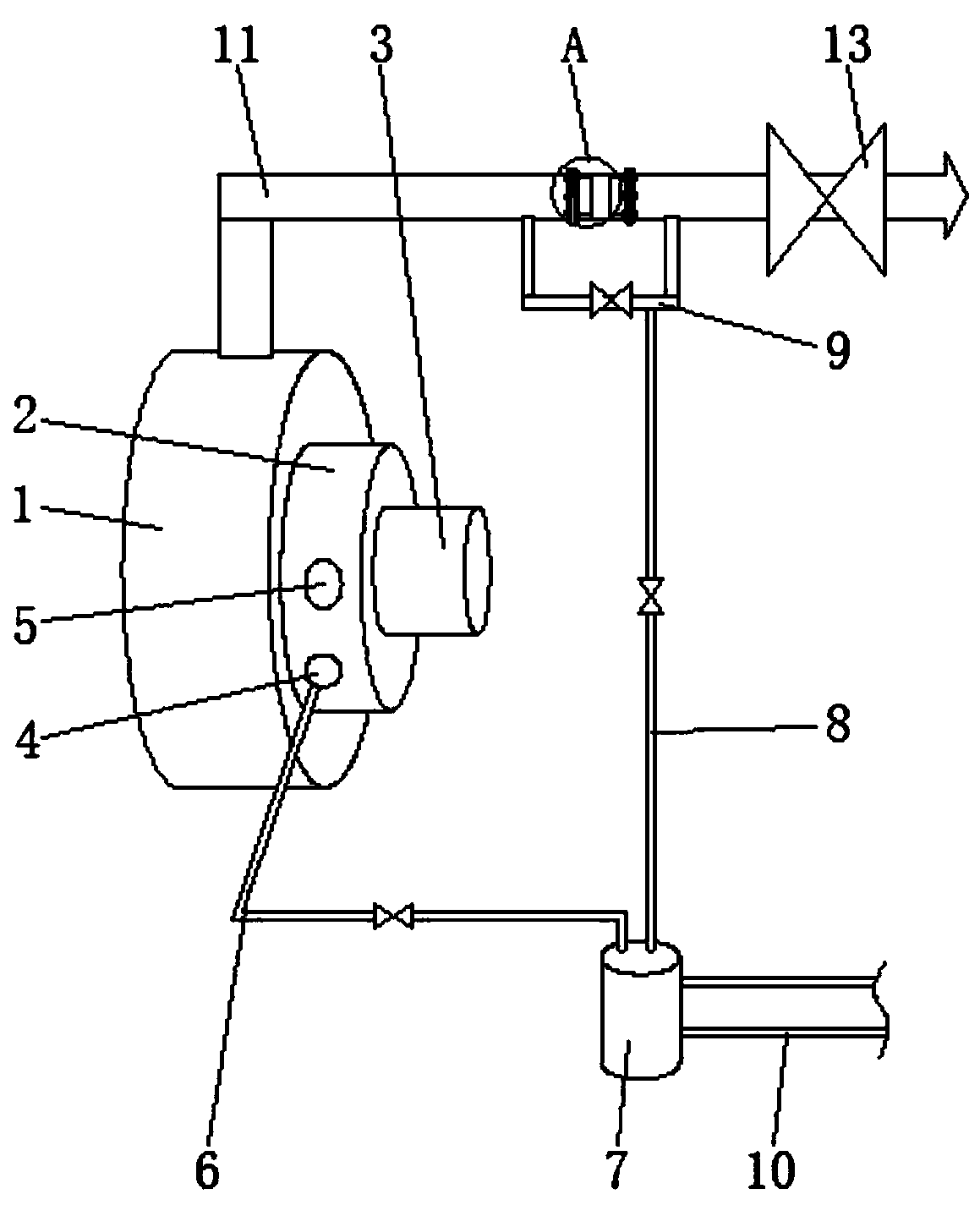

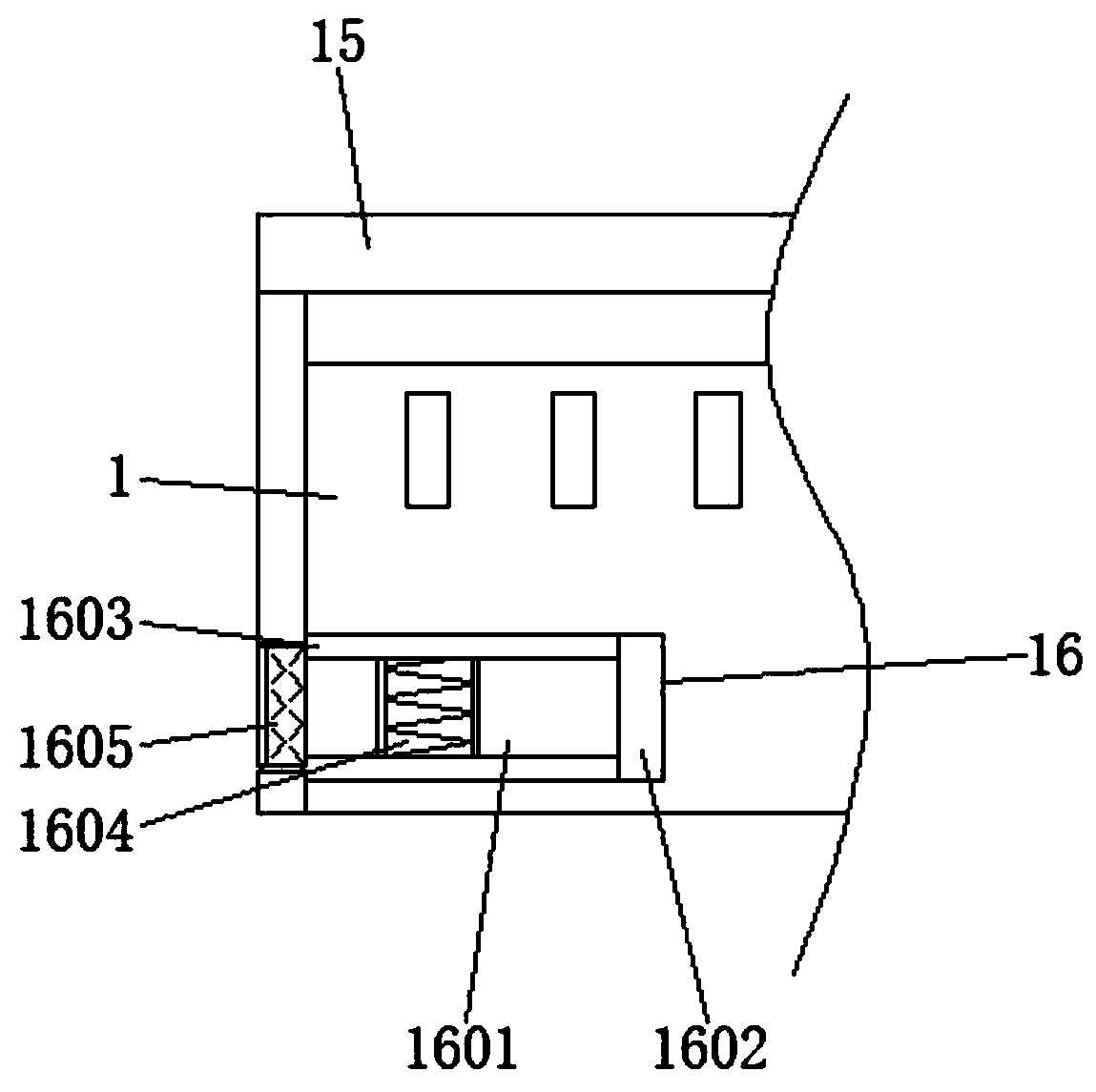

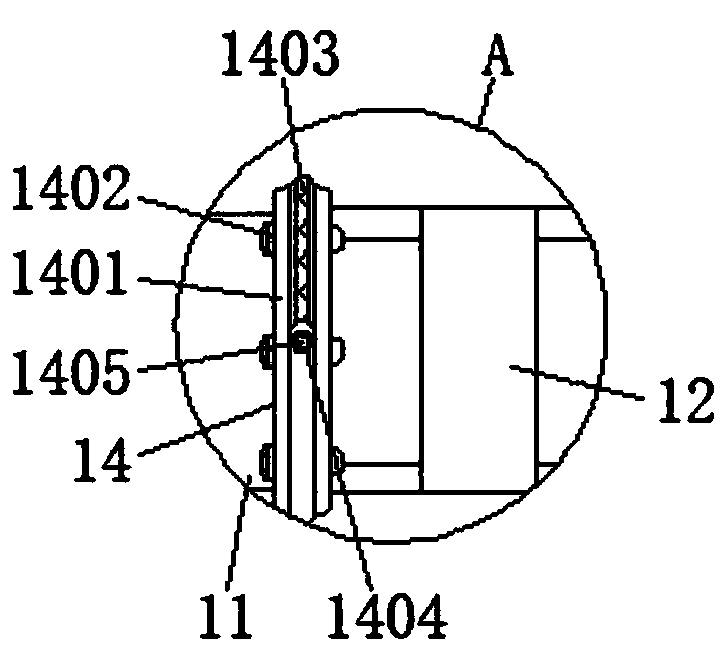

[0025] Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 Schematic diagram of the front view structure provided by the present invention; figure 2 A schematic diagram of a partial sectional structure of the pump body provided by the present invention; image 3 provided for the present invention figure 1 The schematic diagram of the enlarged structure in A. A self-sealing water device for a machine pump includes: a machine pump body 1, a packaged machine seal box 2, a bearing 3, a machine seal water inlet 4, a machine seal water intake 5, a seal water pipeline 6, a heat exchanger 7, a seal Water intake pipeline 8, auxiliary line pipeline 9, circulating water pipe 10, pump outlet pipeline 11, check valve 12, outlet hand valve 13, connecting mechanism 14, flange plate 1401, fixing bolt 1402, sealing sleeve 1403, clamping block 1404, P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com