Special low-heat loss water storage tank for air source heat pump heater

A technology for air source heat pumps and water heaters, which is applied to fluid heaters, lighting and heating equipment, etc. It can solve problems such as bursting and damage of water storage tanks, unfavorable hot water storage, and low heat insulation efficiency, so as to reduce heat loss and avoid The effect of inner box bursting and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

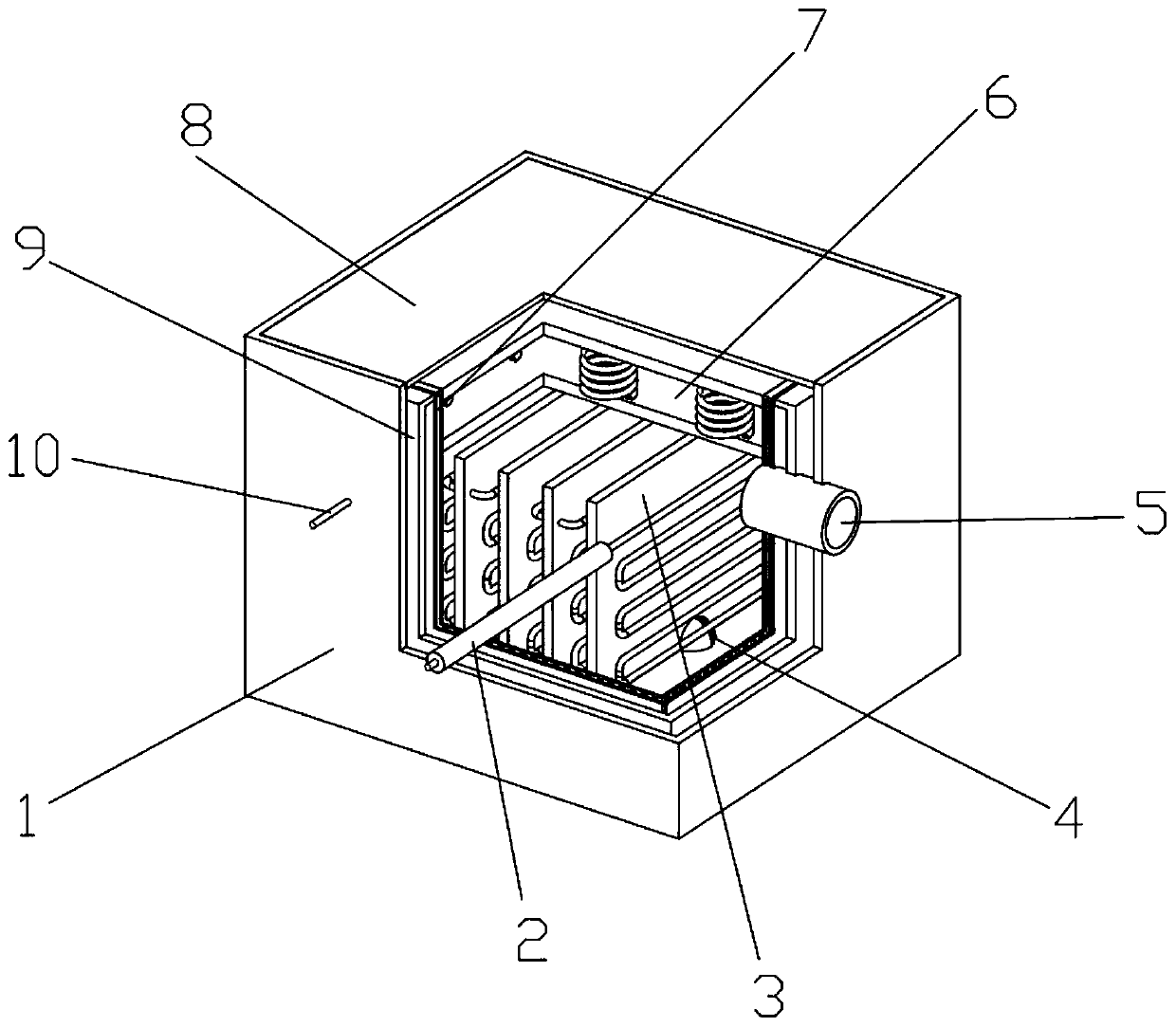

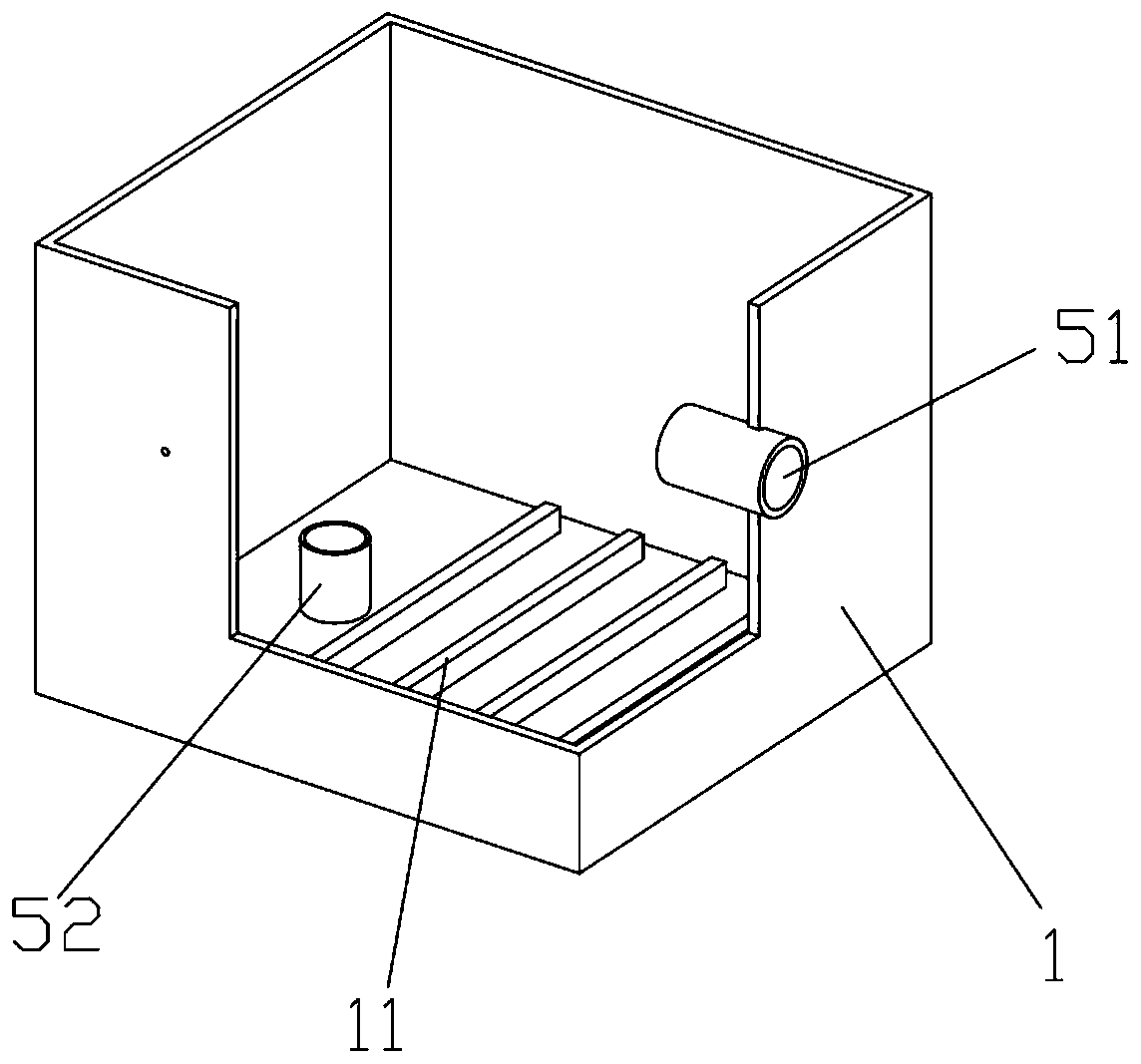

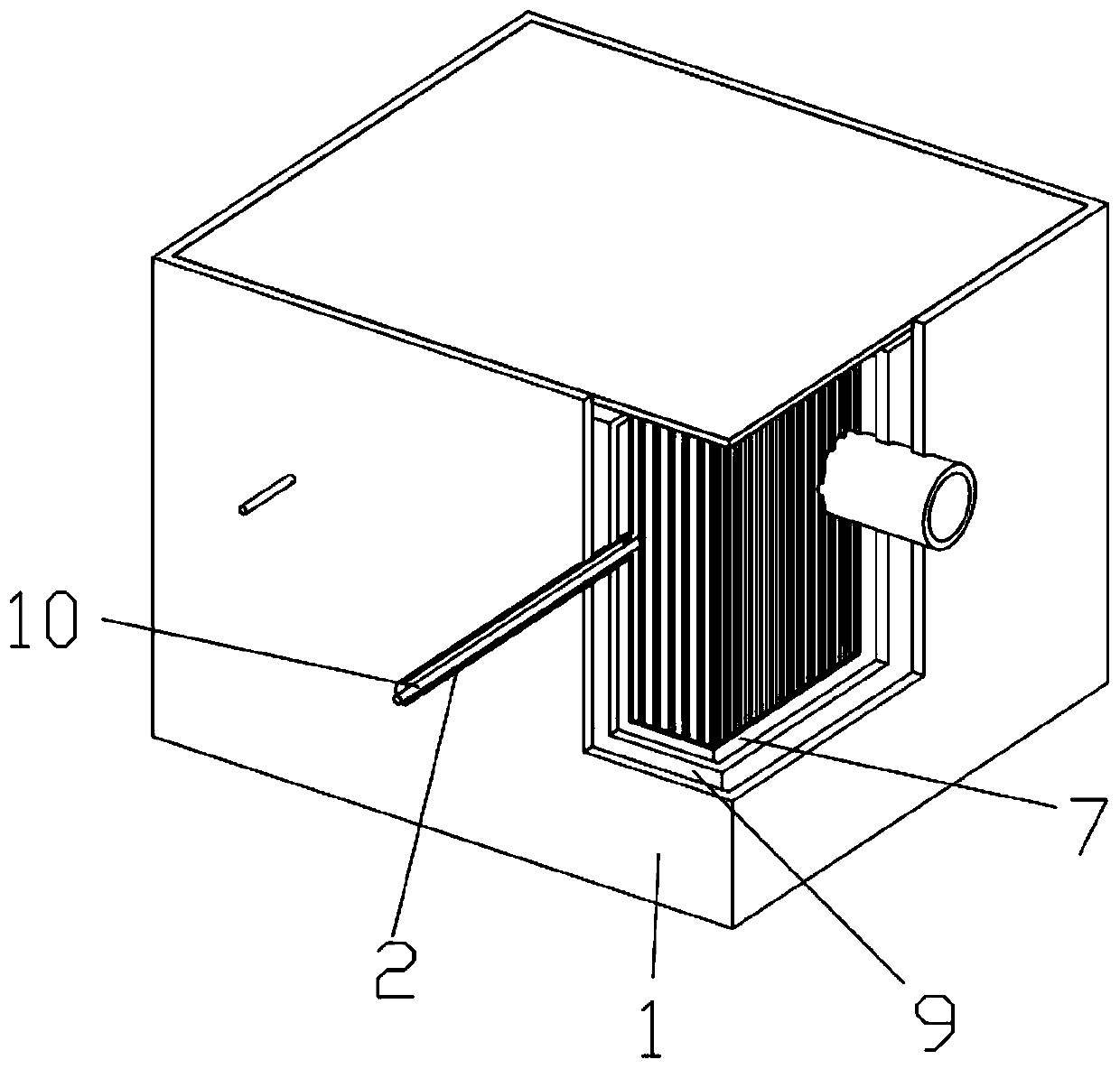

[0030] see Figure 1-9 As shown, a special water storage tank for low heat loss of an air source heat pump water heater includes an outer box 1, a heat energy recovery device 2, a heat insulation baffle 3, a one-way water flow wheel 4, a water delivery pipeline 5, a voltage stabilizing device 6, The inner box 7, the upper cover of the outer box 8, the heat insulation box 9 and the heating pipeline 10 are characterized in that the heat insulation box 9 is set on the outside of the inner box 7, and the upper end of the heat insulation box 9 is fixedly connected with the upper edge of the inner box 7, and the outer The box 1 is set on the outside of the heat insulation box 9, and the bottom surface of the outside of the heat insulation box 9 is fixedly connected with the bottom surface of the inner side of the outer box 1 through the fixing frame 11. The upper end of the outer box 1 is fixed with an outer box upper cover 8, and the upper end of the outer box 1 is far away Higher ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com