Freezing and thawing machine for freezing and thawing process treatment of biopharmaceutical material

A biopharmaceutical material, freeze-thaw technology, applied in the field of freeze-thaw machines, can solve the problems of asynchronous temperature processing, low production efficiency, no temperature record, etc., and achieve the effects of beautiful molding, improving production yield, and beautiful finished product molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention more obvious and understandable, the preferred embodiments are described in detail as follows in conjunction with the accompanying drawings:

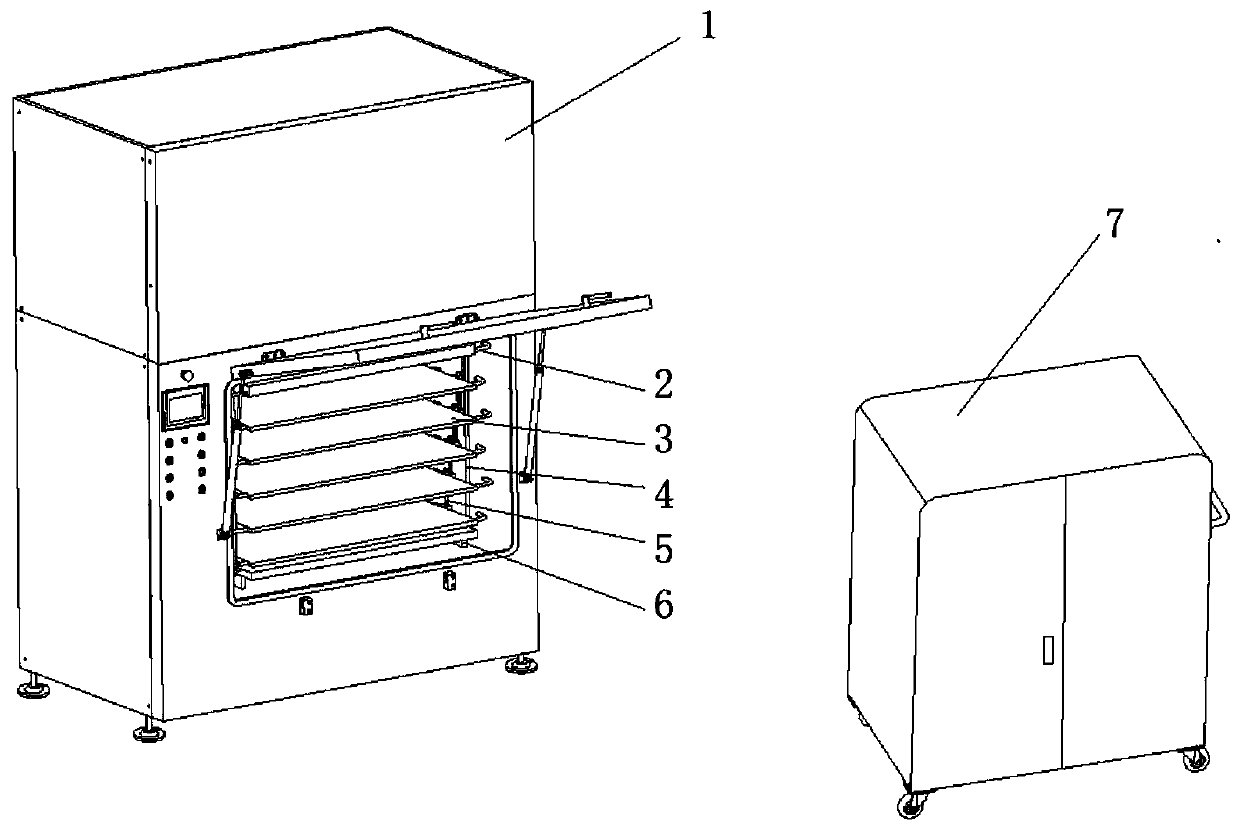

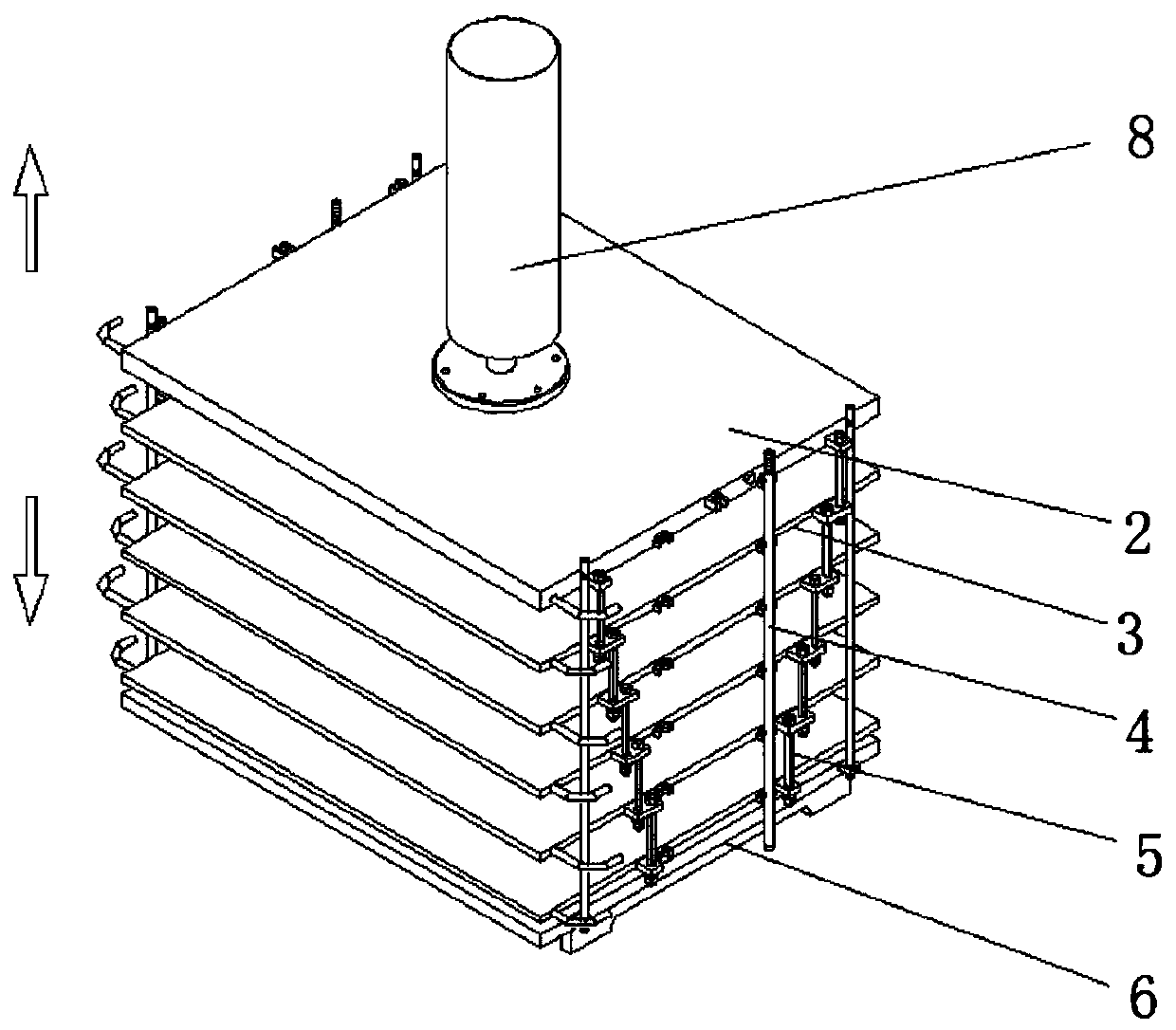

[0020] Such as Figure 1-2 As shown, the present invention provides a kind of freezing-thawing machine that is used for biopharmaceutical material freezing, thawing process, comprises dividing plate 3, guide bar 4, boom 5, support frame 6 and driving mechanism 8; In freezing-thawing machine 1 A partition 3 arranged in a horizontal layer is provided, and the surfaces of the upper and lower partitions 3 are parallel and corresponding; The surface of the board 3 is connected to the guide rod 4 of each partition 3; a suspender 5 for supporting and limiting the relative position of the partition is arranged between the upper and lower corresponding partitions 3; There is a support frame 6; a driving mechanism 8 is provided above the uppermost partition to drive the upper and lower partitions 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com