Natural gas sand detection device

A detection device, natural gas technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of easy deviation of detection results, inaccurate results, corrosion of detection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

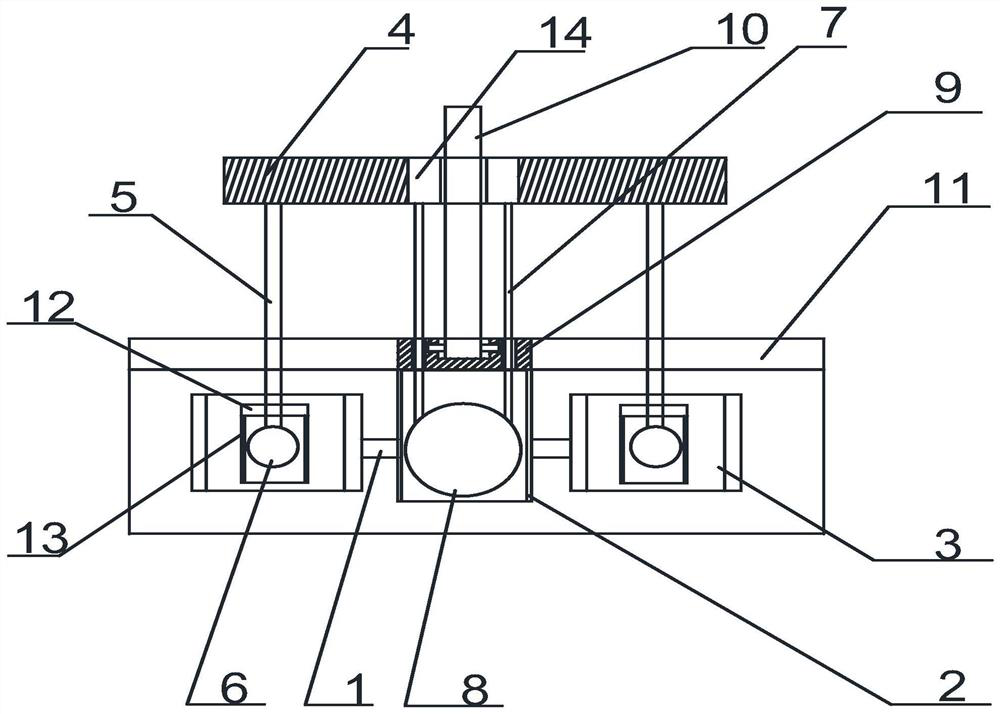

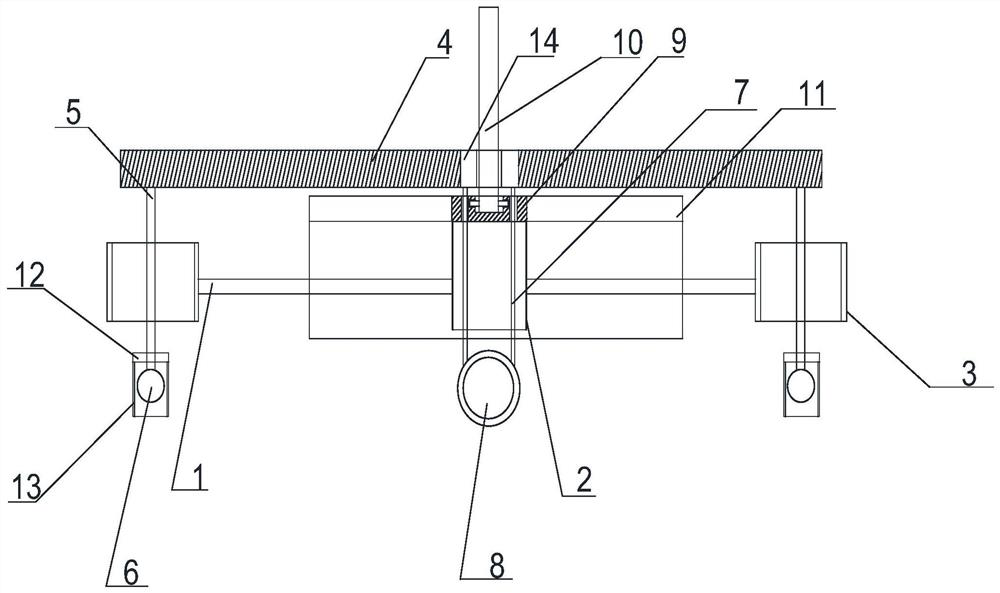

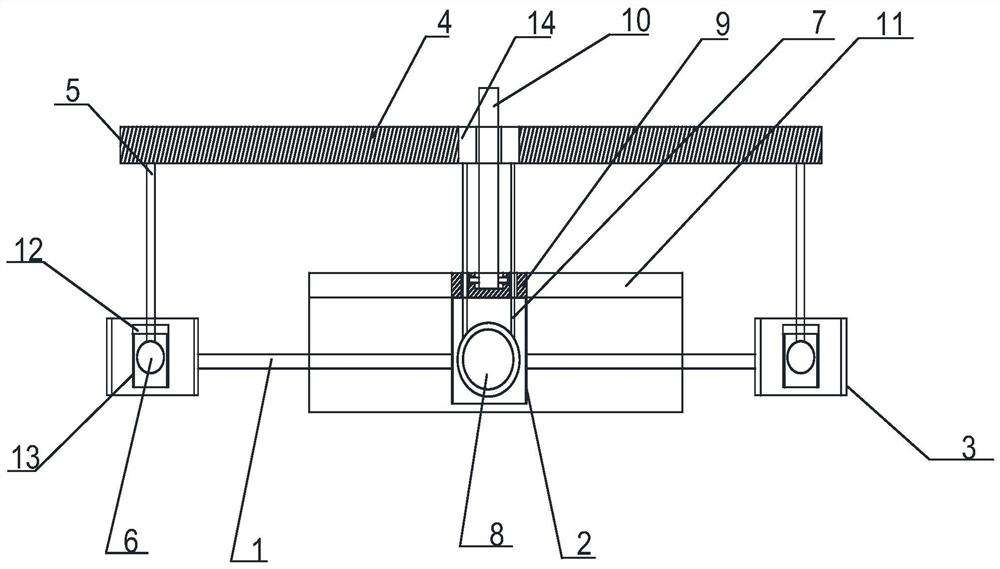

[0048] Such as figure 1 with 4 As shown, the device includes six first telescopic rods 1 and six second telescopic rods 4, one end of the first telescopic rods 1 is connected to the side of the first fixed cylinder 2 with the lower end open, and the other end is connected to the lower end open respectively. The side of the second fixed cylinder 3 is connected, and the first telescopic rod 1 is evenly distributed on the plane where the cross section of the first fixed cylinder 2 is located. After the first telescopic rod 1 is stretched, its structure is as follows: Figure 5 As shown; the second fixed cylinder 3 is fixed on the inner wall of the detection pipeline by the telescopic support of the first telescopic rod 1;

[0049] The upper end of the first fixed cylinder 2 passes through the rotating shaft and an end of the adjustment rod 10, the third fixed cylinder 14 is threaded on the adjustment rod 10, one end of the second telescopic rod 4 is connected with the side of th...

Embodiment 2

[0057] On the basis of Embodiment 1, the first connecting rod 5 is provided with two mutually perpendicular fixed rods 15, and the upper end of the second fixed cylinder 3 is provided with a groove 16 corresponding to the fixed rods 15. The structure is as follows: Figure 7 As shown, when the distance between the first telescopic rod 1 and the second telescopic rod 4 is shortened, the second telescopic rod 4 drives the first connecting rod to move downward, and the fixed rod 15 is snapped into the groove 16 from above the groove 16 , the structure is as Figure 8 As shown, after the first telescopic rod is stretched and stretched, when the first telescopic rod is required to drive the second telescopic rod to stretch, under the action of the fixed rod, the first connecting rod can be used to drive the second telescopic rod to stretch together, further improving Use efficiency.

[0058] At the same time, if Figure 8 As shown, the first connecting rod 5 is covered with a pro...

Embodiment 3

[0060] Such as Figure 4 , 5 , 7, 8 and Figure 9 As shown, a protective shell 17 is also provided on the upper end of the first fixed cylinder 2, the upper end of the first fixed cylinder 2 is connected with a connecting plate 9, the upper end of the connecting plate 9 is provided with a connecting groove, and the inner wall of the connecting groove is provided with a ring-shaped Groove, the side of the lower end of the adjustment rod 10 is provided with an annular projection, which corresponds to the annular groove, and then the adjustment rod is connected to the connecting plate 9 through the annular projection, and can rotate on the connecting plate 9. Such as Figure 8 with 9 As shown, the protective case 17 includes an upper plate 11 and two parallel side plates, the upper plate 11 is provided with a slot, the first connecting rod passes through the slot and slides along the slot when the first telescopic rod stretches, wherein When the first telescopic rod 1 is shor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com