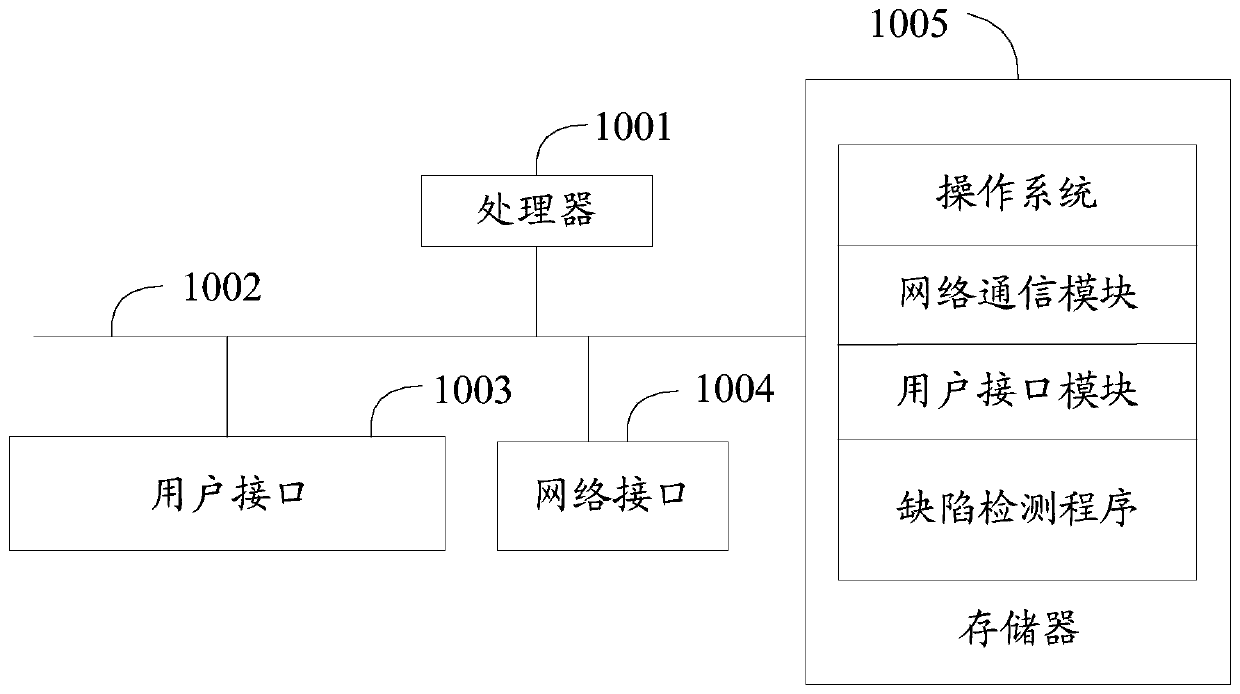

Defect detection method and device, defect detection equipment and computer storage medium

A defect detection and defect technology, applied in computing, image data processing, instruments, etc., can solve problems such as inaccurate detection results and inaccurate product defect detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

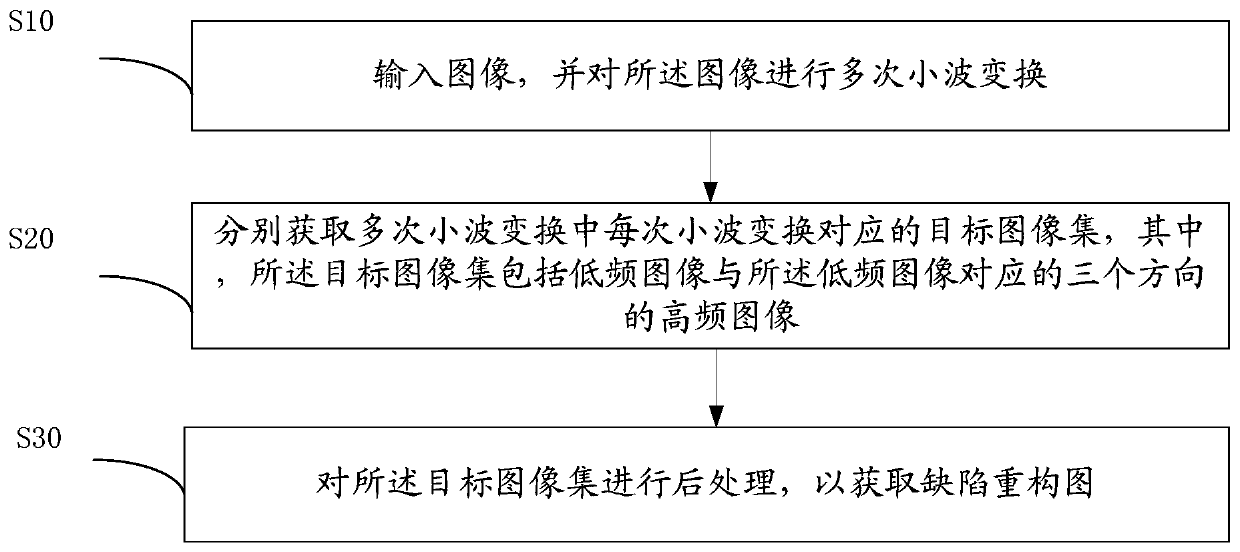

[0096] Based on the first embodiment, a second embodiment of the method of the present invention is proposed. In this embodiment, step S31 includes,

[0097] Step S311, performing preprocessing on the low-frequency image to obtain a region to be detected corresponding to the low-frequency image;

[0098] Step S312, expanding the area to be detected to obtain an expanded area;

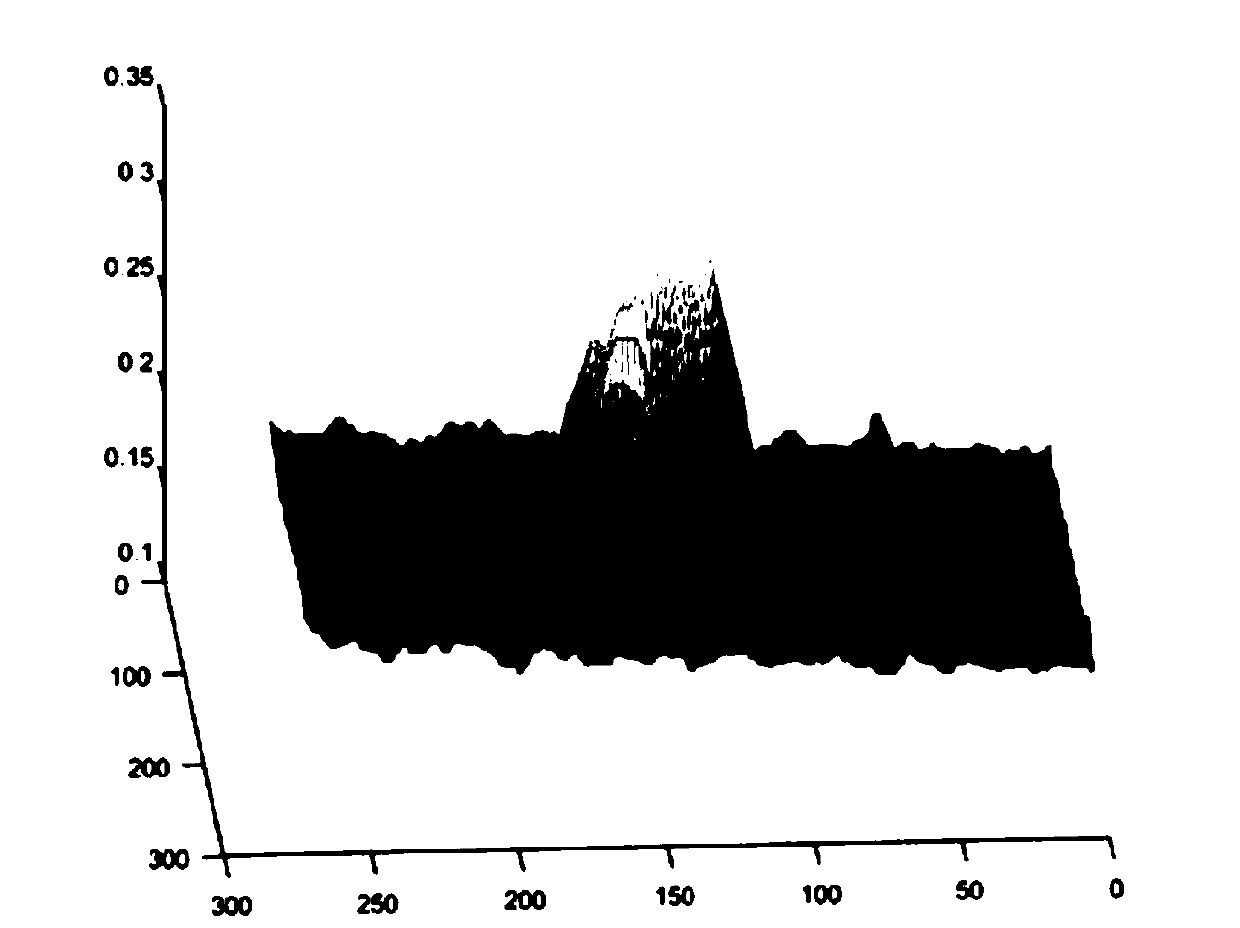

[0099] Step S313, performing surface fitting on the region to be detected and the extended region to obtain a defect image.

[0100] In this embodiment, after the low-frequency image is obtained, the low-frequency image is preprocessed to obtain the defect area corresponding to the low-frequency image. In this embodiment, grayscale is used to preprocess the low-frequency image. Specifically, the steps S311 also includes,

[0101] Step S3111, performing grayscale processing on the low-frequency image to obtain a first grayscale image;

[0102] Step S3112, performing low-pass filtering processing on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com