Novel poultry hatching egg washing machine and cleaning method thereof

A technology for egg washing machine and breeding eggs, which is applied in poultry industry, application, animal husbandry and other directions, can solve the problems of clogging of egg washing machine, affecting cleaning effect, incomplete cleaning, etc., to reduce the probability of clogging, ensure cleaning effect, The effect of increasing economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

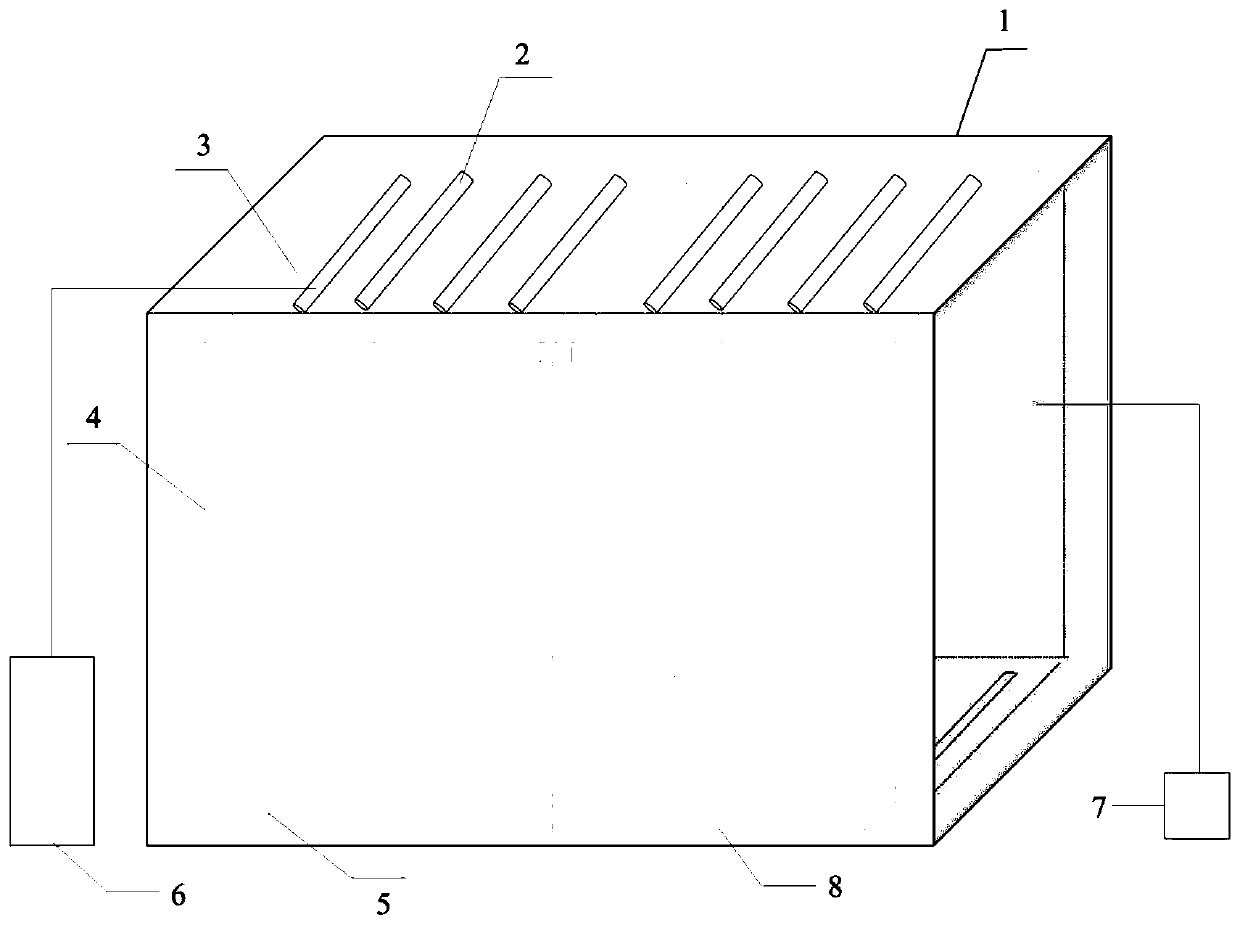

[0031] A new poultry breeding egg washing machine, mainly including a box body, a spray system, an egg washing car, an egg car track, and a box door;

[0032] The outer side of the box body is provided with a car entrance, and the floor of the box body is provided with an egg trolley track for the egg washing car to enter and exit. The door is connected to the box body through the rotating shaft; the top of the box body is provided with a spray system, including water pipes and spray plates; For egg trolleys: the egg cleaning fluid passes through the spray plate to clean the eggs on the egg trolleys.

Embodiment 2

[0034] A cleaning method for a novel poultry breeding egg washing machine comprises the following specific steps:

[0035] (1) Preparation of egg washing liquid: add the prepared egg washing liquid into the external water tank of the egg washing machine;

[0036] (2) Egg tray: before cleaning, put the egg tray on the egg trolley, push the egg trolley into the egg washing machine, and close the box door;

[0037] (3) Washing eggs: press the cleaning switch on the panel of the control cabinet, use the water pipe on the top of the egg washing box to supply water, and rinse the eggs through the spray system below;

[0038] (4) Drying: After the eggs are washed, push the trolley out of the egg washing machine and dry the water.

Embodiment 3

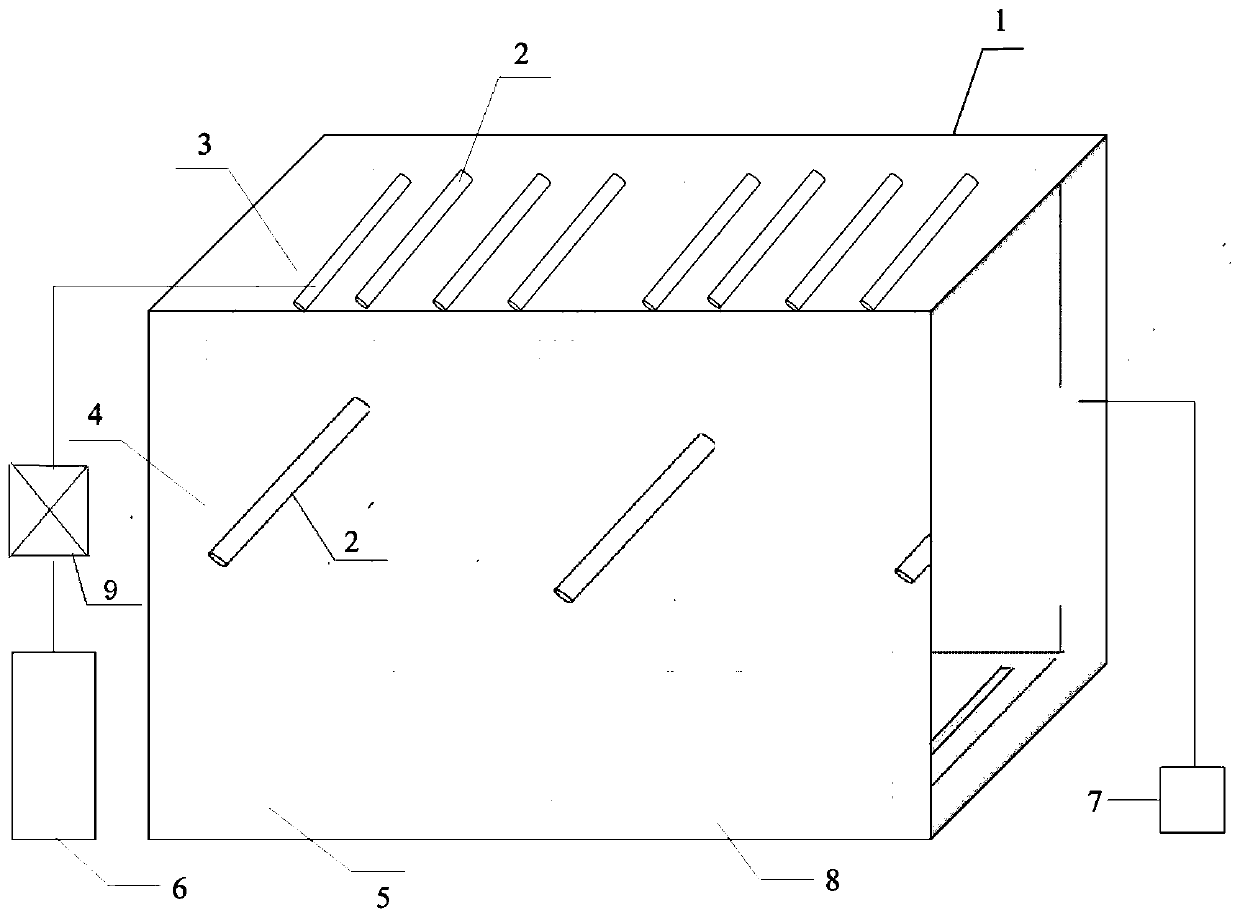

[0040] A new poultry breeding egg washing machine, mainly including a motor, a box body, a spraying system, an egg washing trolley, an egg trolley track, and a box door;

[0041] The outer side of the box body is provided with a car entrance, and the floor of the box body is provided with an egg trolley track for the egg washing car to enter and exit. Door, the box door is connected with the box body through the rotating shaft; the top of the box body is provided with a spray system, including a water pipe and a spray plate; the water pipe is connected to an external pressure water source, and the bottom of the water pipe is provided with multiple nozzles, and the nozzles are facing the spray plate; the egg cleaning fluid passes through the spray plate to clean the eggs on the trolley; the spray plate bracket is vertically provided with a spray plate, and a number of spray water pipes are horizontally provided on the spray plate, and the spray plate There are also multiple spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com