Scaling machine for tilapia processing and processing method thereof

A technology for tilapia and fish scales, which is applied in the direction of fish cleaning/descaling, conveyor objects, cleaning devices, etc., which can solve the problems of inconvenient and continuous fish scale removal, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

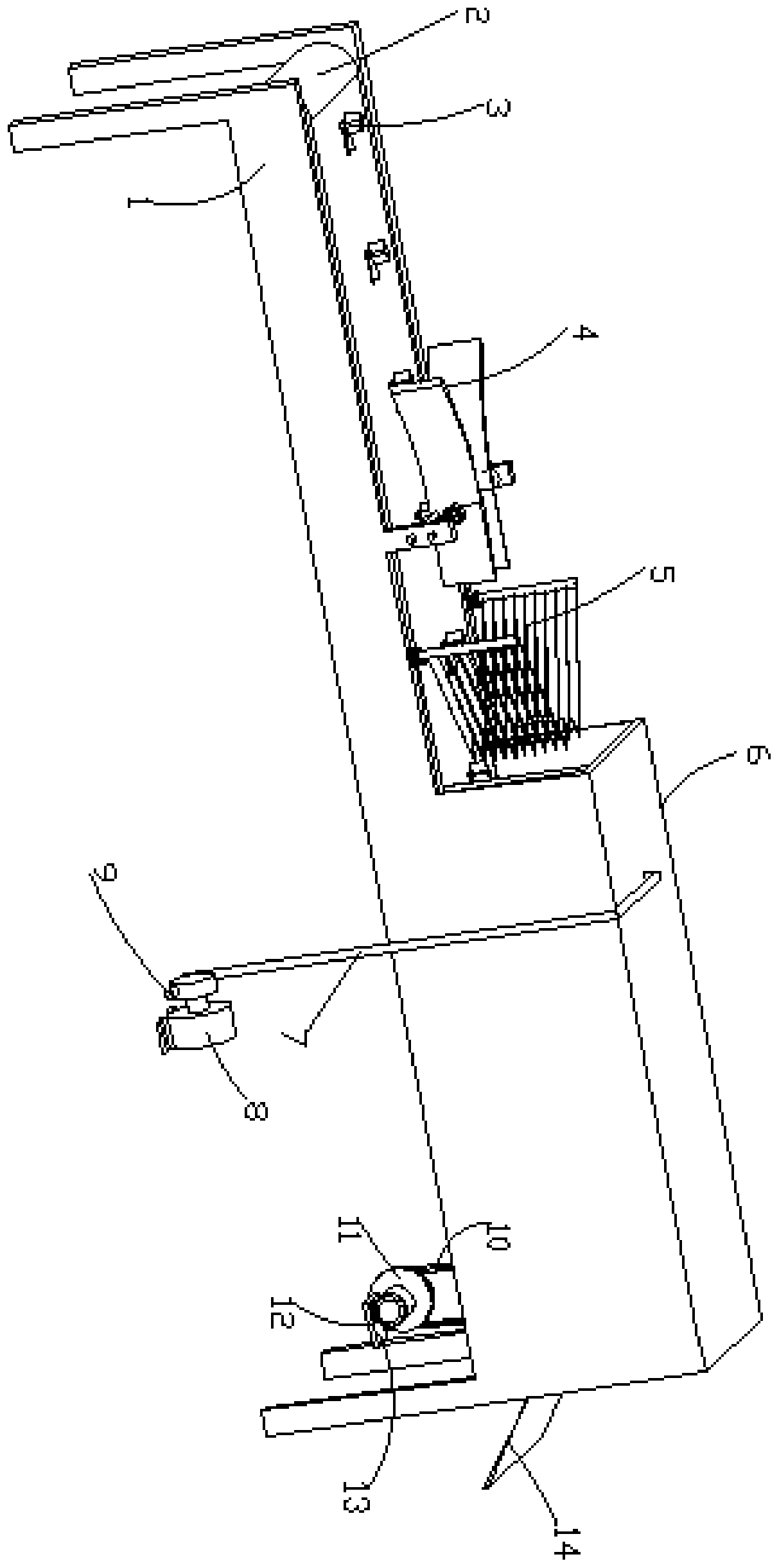

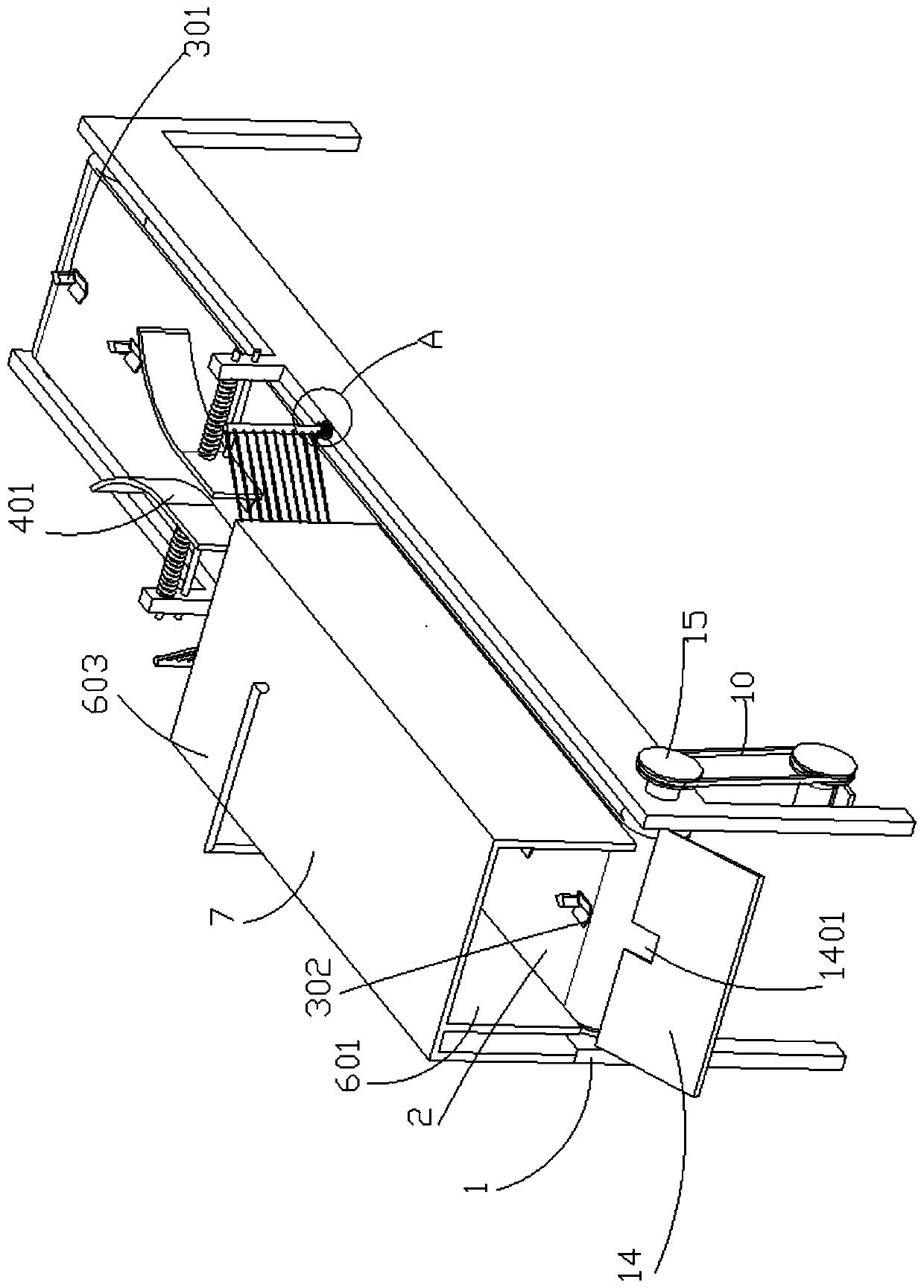

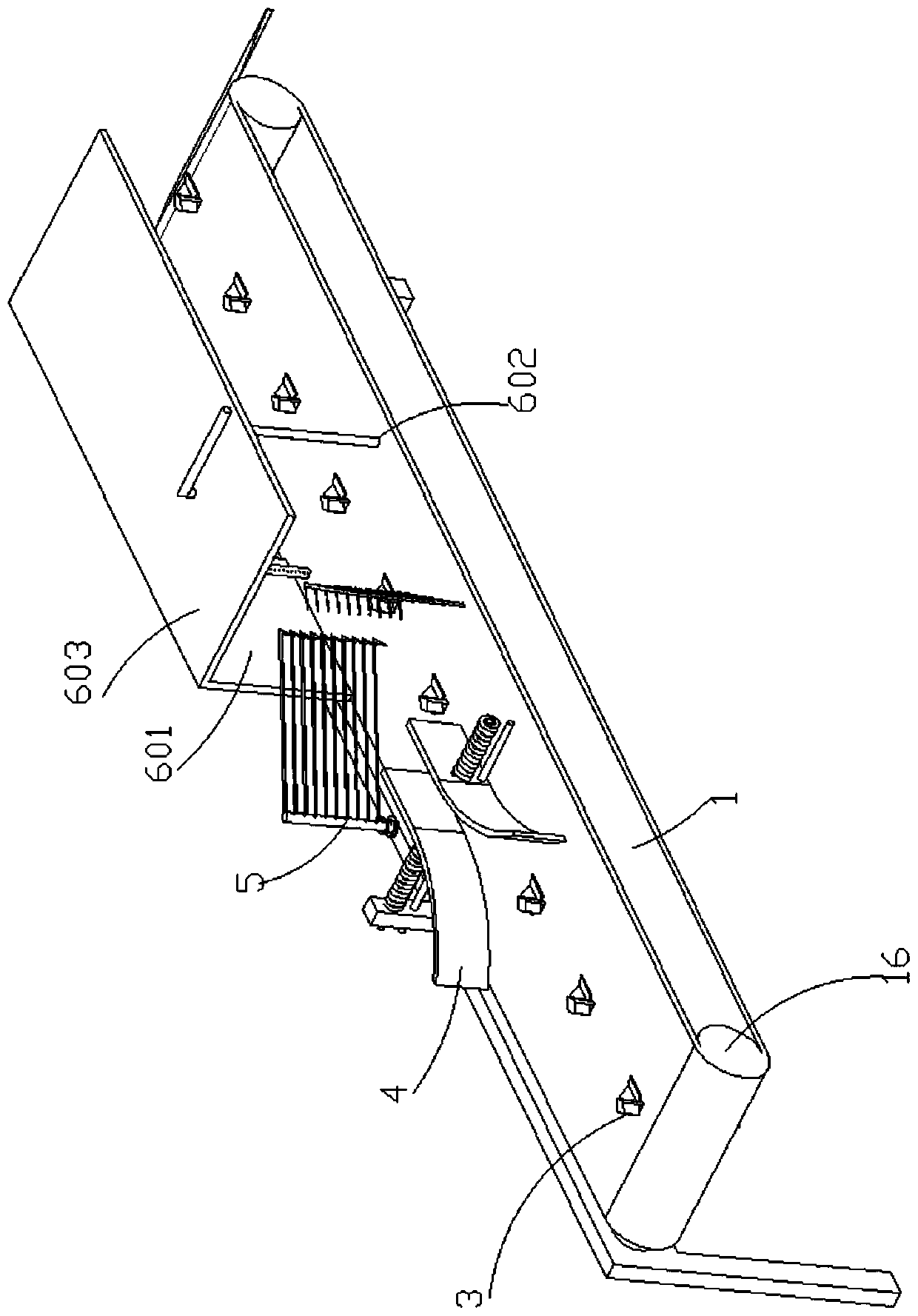

[0041] Such as Figure 1-8 A descaling machine for tilapia processing is shown, including a support 1, a conveyor belt 2, a fixed structure 3, a centralizing structure 4, a rake scale structure 5, a scale removal structure 6, an outlet pipe 7, a water pump 8, an inlet pipe 9, and a belt 10. Driving pulley 11, support plate 12, driving motor 13, blanking plate 14, driven pulley 16 and turning roller 17, the inner wall of support 1 is connected with turning roller 17 through fixedly connected bearing 502, wherein a group of turning rollers 17 The rotating shaft runs through the support 1 and is fixedly connected with a driven pulley 16, the driven pulley 16 is movably connected with a belt 10, the side wall of the support 1 is fixedly connected with a support plate 12, the drive motor 13 is fixedly installed on the support plate 12, and the output end of the drive motor 13 The driving pulley 11 is fixedly connected, and the driving pulley 11 is movably connected with the belt 10...

Embodiment 2

[0044] Embodiment 2 is a further improvement to Embodiment 1.

[0045] Such as Figure 1-8 A descaling machine for tilapia processing is shown, comprising a support 1, a conveyor belt 2, a fixed structure 3, a centralizing structure 4, a rake scale structure 5, a descaled structure 6, an outlet pipe 7, a water pump 8, an inlet pipe 9, Belt 10, driving pulley 11, support plate 12, drive motor 13, blanking plate 14, driven pulley 16 and turning roller 17, support 1 inner wall is connected with turning roller 17 by the bearing 502 that is fixedly connected, wherein a group of turning roller The rotating shaft of 17 runs through support 1 and is fixedly connected with driven pulley 16, and driven pulley 16 is movably connected with belt 10, and the output end of driving motor 13 is fixedly connected with driving pulley 11, and driving pulley 11 is movably connected with belt 10; Fixedly connected with a fixed structure 3, the fixed structure 3 includes a diamond-shaped knife 301,...

Embodiment 3

[0046] Embodiment 3 is a further improvement to Embodiment 1.

[0047] Such as Figure 1-8 A descaling machine for tilapia processing is shown, comprising a support 1, a conveyor belt 2, a fixed structure 3, a centralizing structure 4, a rake scale structure 5, a descaled structure 6, an outlet pipe 7, a water pump 8, an inlet pipe 9, Belt 10, driving pulley 11, support plate 12, drive motor 13, blanking plate 14, driven pulley 16 and turning roller 17, support 1 inner wall is connected with turning roller 17 by the bearing 502 that is fixedly connected, wherein a group of turning roller The rotating shaft of 17 runs through support 1 and is fixedly connected with driven pulley 16, and driven pulley 16 is movably connected with belt 10, and the output end of driving motor 13 is fixedly connected with driving pulley 11, and driving pulley 11 is movably connected with belt 10; Fixedly connected with a fixed structure 3, the fixed structure 3 includes a diamond-shaped knife 301,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com