Waste gas treatment equipment for industrial environmental protection

A waste gas treatment equipment and environmental protection technology, applied in the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of reducing the service life of activated carbon, clogging activated carbon, and reducing the adsorption effect of activated carbon adsorption layer, and achieving easy cleaning and dust removal. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

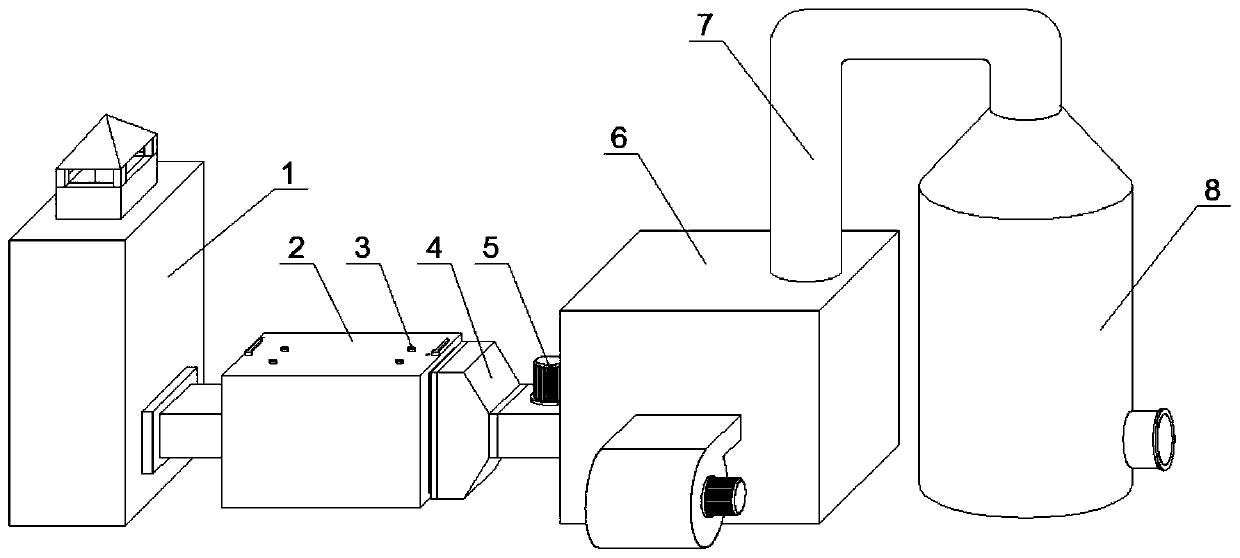

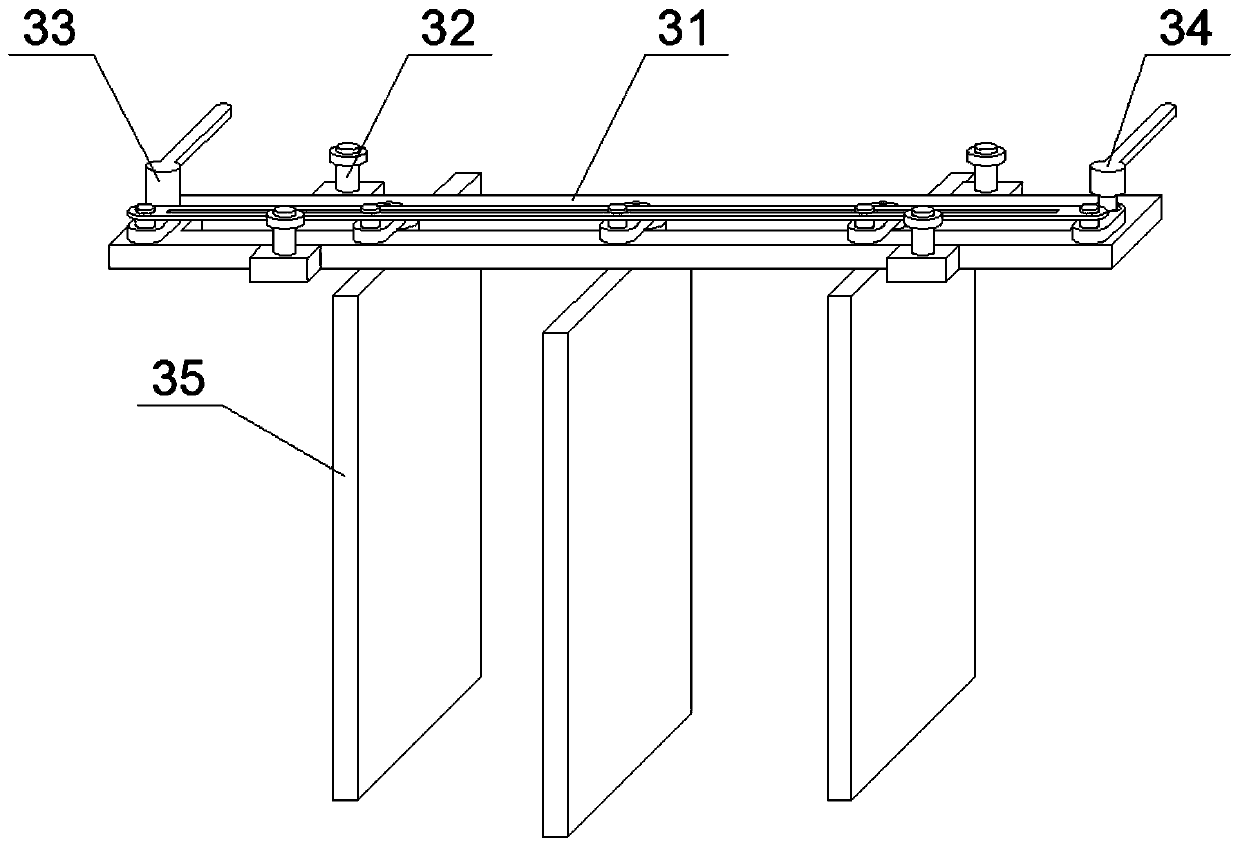

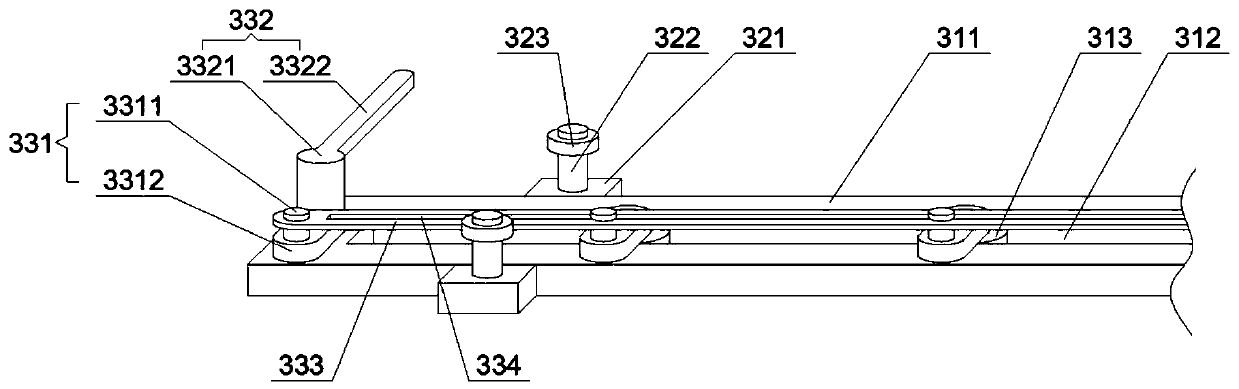

[0020] Such as Figure 1 ~ Figure 4 As shown, the waste gas treatment equipment for industrial environmental protection provided in this embodiment includes a settling tower 8, a heat drying chamber 6, a gas conveying hood 4, a dust removal chamber 2 and an activated carbon adsorption tower 1 connected successively through a pipeline 7, and the settling tower The lower part of the settling tower 8 is provided with an air inlet, and the top of the settling tower 8 is connected with the heat drying chamber 6 through a U-shaped pipe 7, so that the passing dust-laden gas can be preliminarily settled. ) after the heat drying, the water vapor is removed in one step, the pipeline 7 between the heat drying chamber 6 and the gas delivery cover 4 is equipped with an air pump 5, and the air pump 5 can circulate the dust-containing (a small amount) dry gas in the heat drying chamber 6 Pumped into the dust removal chamber 2 through the gas transmission cover 4, the dust-containing (small a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com