A kind of biological deodorant and preparation method thereof

A deodorant and biological technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of short duration of treatment effects, etc., to prolong the effective time, accelerate the onset time, and fast onset time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

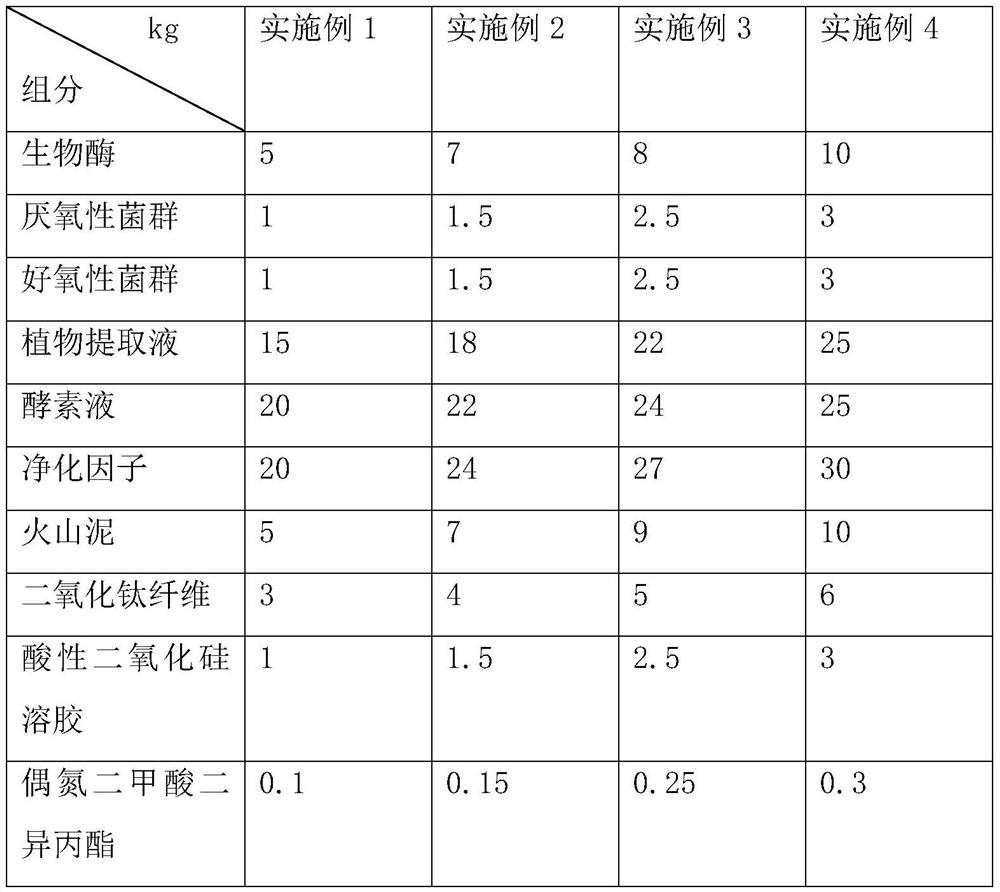

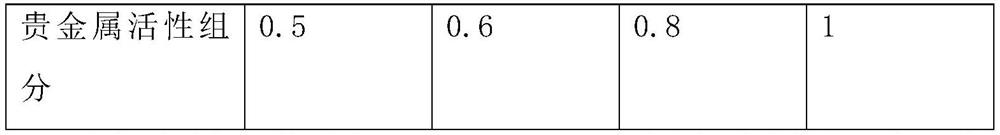

Examples

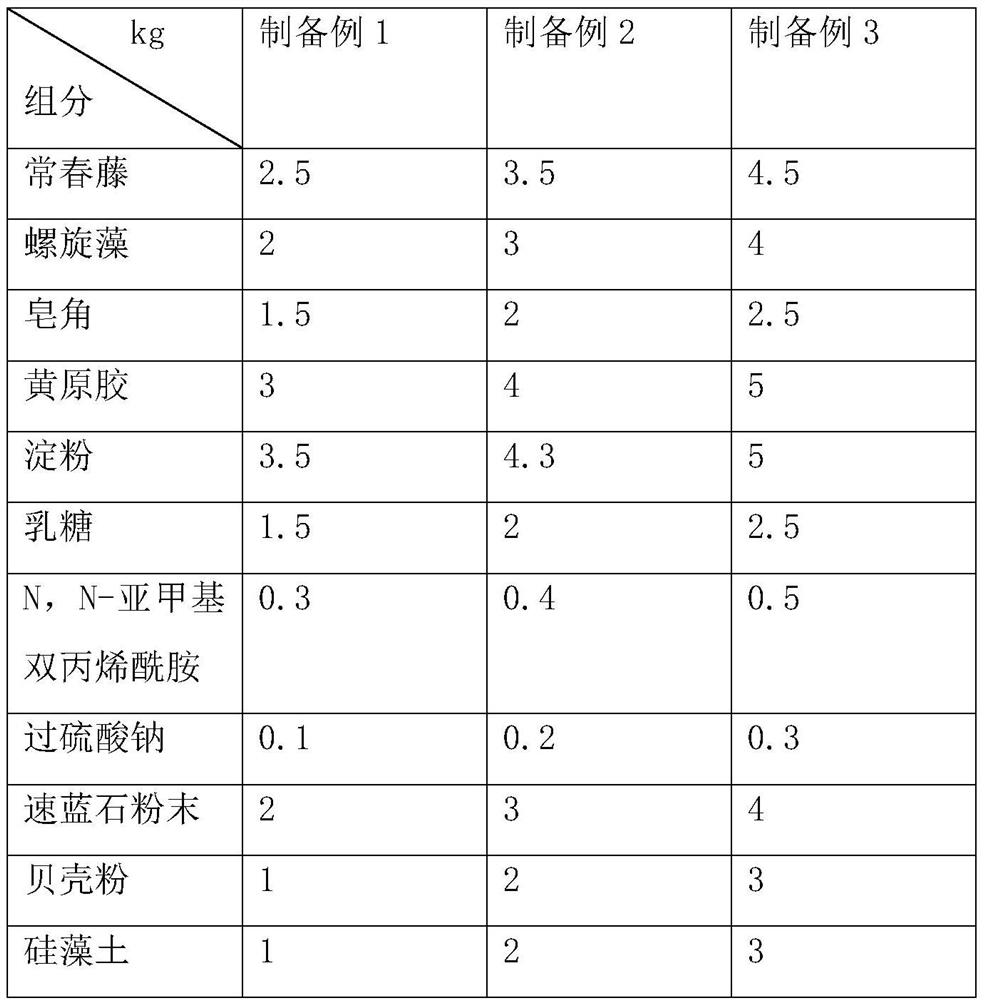

preparation example 1-3

[0042] Preparation Example 1: (1) According to the ratio of raw materials in Table 1, 2.5kg of ivy, 2kg of spirulina and 1.5kg of saponins were freeze-dried, mixed and milled, passed through a 150-mesh sieve to obtain plant powder, and freeze-dried The temperature is -40°C, and the time is 24h;

[0043] (2) Mix 3kg of xanthan gum and 3.5kg of starch, gelatinize in a water bath at 90°C, add 0.3kg of N,N-methylenebisacrylamide and 0.1kg of sodium persulfate after cooling, stir for 2 hours, and add 1.5kg of lactose and plant powder, mixed evenly to obtain an intermediate;

[0044] (3) Mix 2kg of sapphire powder, 1kg of diatomaceous earth and 1kg of shell powder evenly, add the intermediate, stir evenly, and dry at 40°C to obtain the purification factor.

[0045] The raw material ratio of purification factor in table 1 preparation example 1-3

[0046]

preparation example 2

[0047] Preparation example 2: (1) according to the raw material proportioning in table 1, 3.5kg ivy, 3kg spirulina and 2kg saponins are carried out freeze-drying, mix and grind, cross 200 mesh sieves, make plant powder, freeze-drying temperature -45℃, the time is 36h;

[0048] (2) Mix 4kg xanthan gum and 4.3kg starch, gelatinize in a water bath at 100°C, add 0.4kg N, N-methylenebisacrylamide and 0.2kg sodium persulfate after cooling, stir for 2.5h, add 2kg lactose and plant powder, mixed evenly to obtain an intermediate;

[0049] (3) Mix 3 kg of sapphire powder, 2 kg of diatomaceous earth and 2 kg of shell powder evenly, add the intermediate, stir evenly, and dry at 45°C to obtain the purification factor.

preparation example 3

[0050] Preparation Example 3: (1) According to the ratio of raw materials in Table 1, 4.5kg of ivy, 4kg of spirulina and 4kg of saponins are freeze-dried, mixed and milled, and passed through a 200-mesh sieve to obtain plant powder. -50℃, the time is 24h;

[0051] (2) Mix 5kg xanthan gum and 5kg starch, gelatinize in a water bath at 110°C, add 0.5kg N, N-methylenebisacrylamide and 0.3kg sodium persulfate after cooling, stir for 3 hours, add 2.5kg lactose and Vegetable powder, mixed evenly to obtain an intermediate;

[0052] (3) Mix 4kg of sapphire powder, 3kg of diatomaceous earth and 3kg of shell powder evenly, add the intermediate, stir evenly, and dry at 50°C to obtain the purification factor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com